Safety interlocking control system for crane position loading

A technology of safety interlocking and control systems, applied in packaging, distributing devices, transportation and packaging, etc., can solve the problems of static charge not being eliminated, waste, safety hazards, etc., to prolong the discharge time of static electricity and avoid fire and explosion Accidents, the effect of reducing the instantaneous electrostatic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

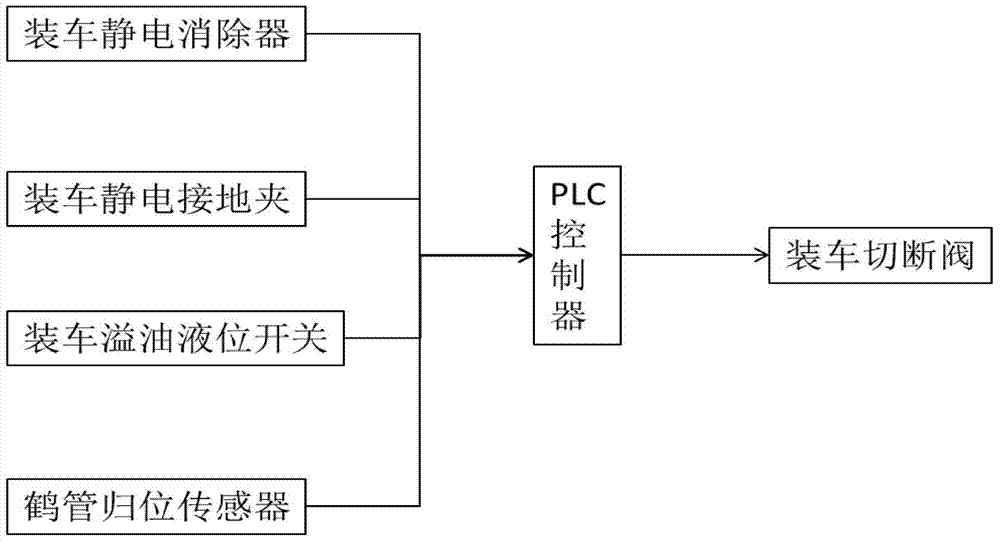

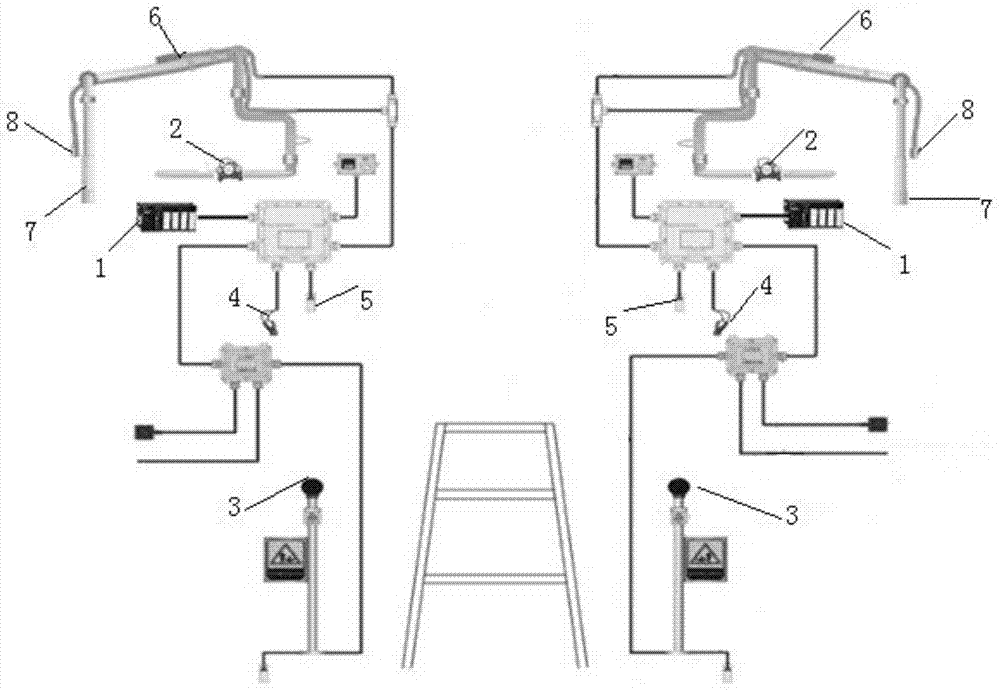

[0015] A crane loading safety interlock control system, including a human body static elimination module for realizing the safe discharge of human static electricity, a vehicle static elimination module for realizing the safe discharge of vehicle static electricity, and a crane tube for detecting the position of the crane tube The homing detection module, the oil overflow alarm module used to detect the oil level, the control module used to receive the signals of the above modules and make judgments, and the action mechanism controlled by the control module to control whether to perform refueling operations, all The above-mentioned control module adopts PLC controller 1, and the above-mentioned action mechanism is the loading cut-off valve 2.

[0016] The human body static elimination module adopts the human body static touch ball 3 made of static subconductor material, the human body static touch ball 3 automatically detects the human body static resistance, safely releases st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com