Three-roller double-zone upper-and-lower-rubber-ring drafting device for ring spinning frames

The invention relates to a drafting device and a technology of a spinning frame, which is applied to the field of a three-roller, double-zone, upper and lower apron drafting device of a ring spinning frame, and can solve the problems of weak controllability of roving sliver, poor yarn quality, and drafting in the second drafting zone. Problems such as low multiples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The following is a further detailed description of the three-roller double-zone upper and lower apron drafting device of the new ring spinning frame in conjunction with the accompanying drawings.

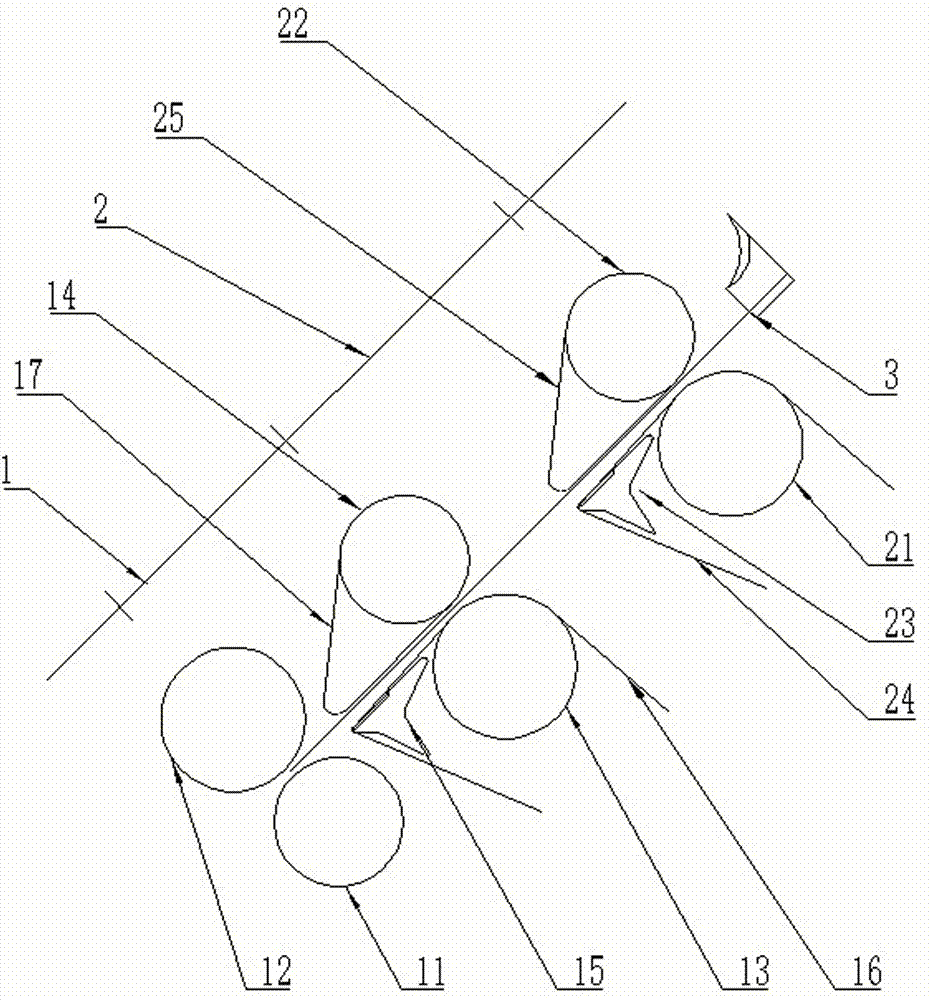

[0008] Depend on figure 1 It can be seen that the three-roller double-zone upper and lower apron drafting device of the ring spinning frame of the present invention includes a first drafting zone 1 and a second drafting zone 2, and the first drafting zone includes a front roller 11, a front rubber Roller 12, a middle roller 13 and a middle iron roller 14 are arranged in the middle of the first drafting zone 1 and the second drafting zone 2, and the front lower pin 15 is set on one side of the roller 13, and the front lower apron 16 passes through the front lower pin 15 Set on the roller 13, the middle iron roller 14 is provided with a front apron 17, the second drafting zone 2 includes a rear roller 21 and a rear iron roller 22, one side of the rear roller 21 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com