Quasi-cuboctahedron tensegrity structure

A technique of tensioning the overall structure and octahedron, which is applied in special structures, building components, building structures, etc., to improve the stress state, facilitate mass production, and facilitate processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

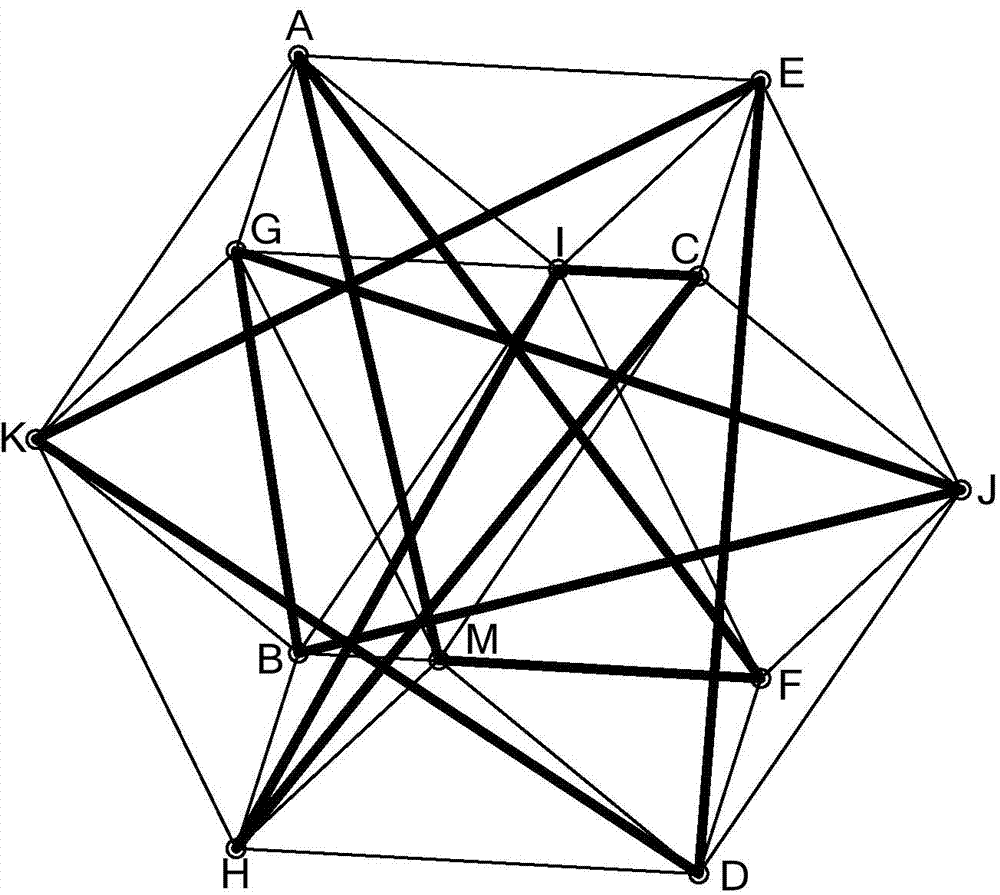

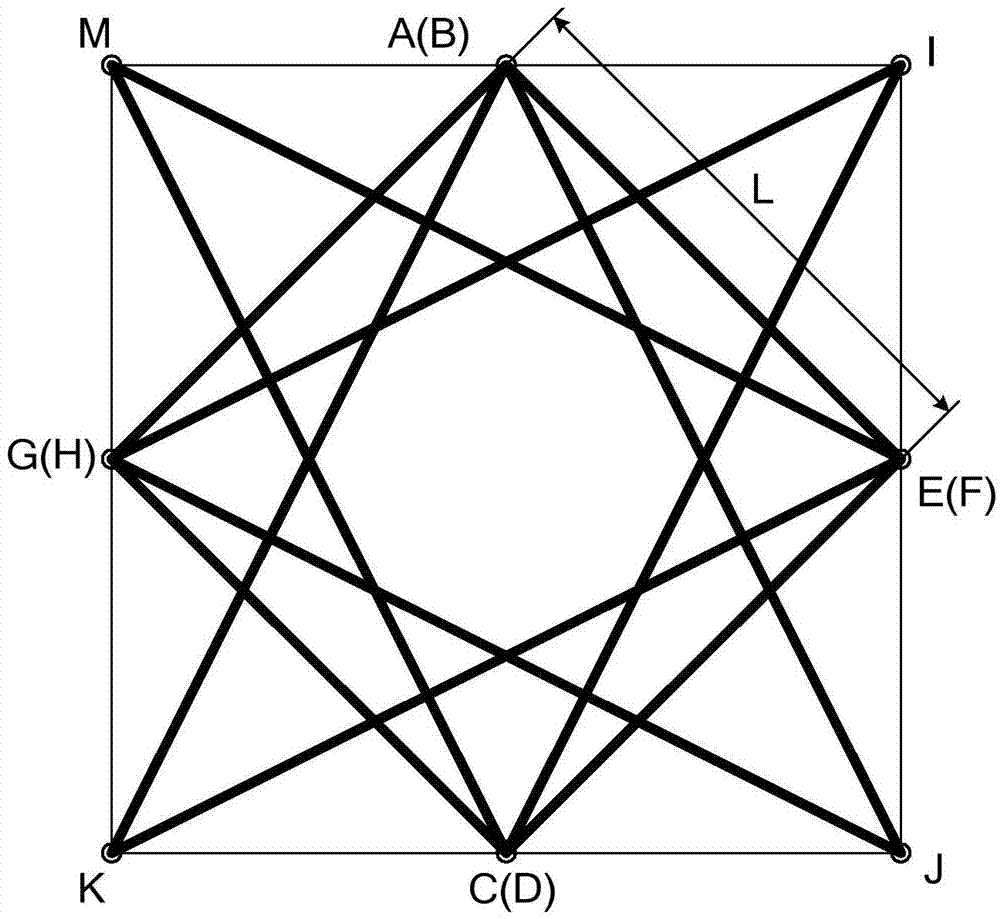

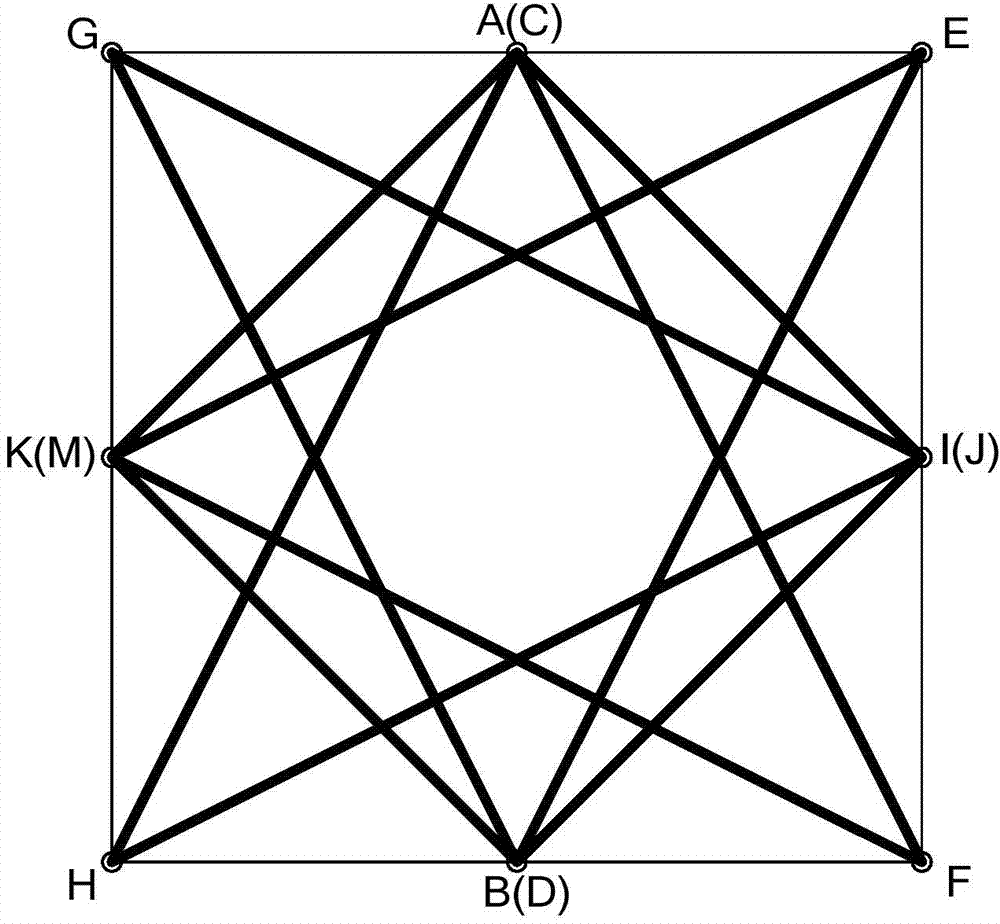

[0019] combine Figure 1~4 , the cubo-octahedral tensegrity structure in the present invention is shaped as a unit obtained by connecting the midpoints of two adjacent sides on the basis of a cube and cutting off eight corners. Therefore, the obtained unit structure has 6 square faces, 8 triangular faces, and 14 faces in total. Because the faces and edges of regular polygons of the same type do not intersect, the number of edges can be obtained by multiplying the number of its sides by the number of faces: 3×8=4×6=24.

[0020] The cubo-octahedral tensegrity overall structure in the present invention is made up of 12 nodes, 24 stay cables and 12 pressure rods, and the 12 nodes are respectively located at 12 vertices of the cubo-octahedron, and are distributed on the same spherical surface, i.e. cubic The circumscribed sphere of the octahedron, the radius of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com