Silencing exhaust hose and diesel generator thereof

A technology of silencer pipes and hoses, which is applied in the direction of silencer devices, exhaust devices, engine components, etc., which can solve the problems of high price and complex structure of silencer devices, and achieve the effect of easy installation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] Embodiment 2 is a kind of oil production generator, and its exhaust port is connected with silencing exhaust hose 1 .

[0036] Working process and principle of the present invention:

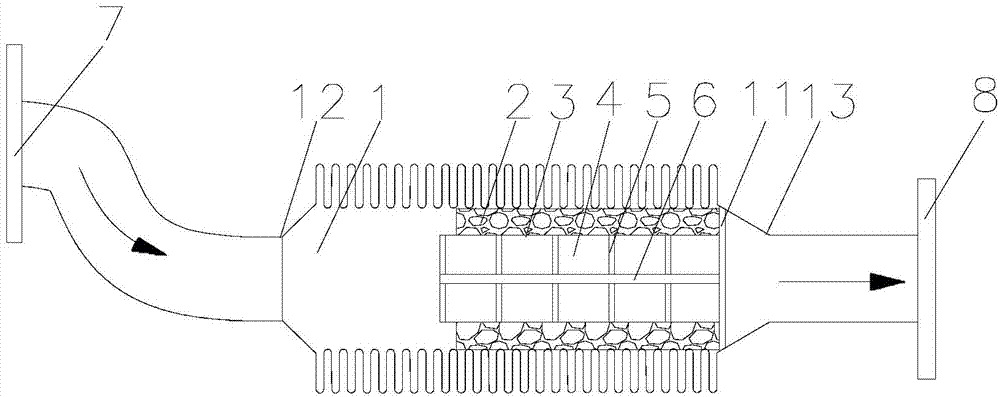

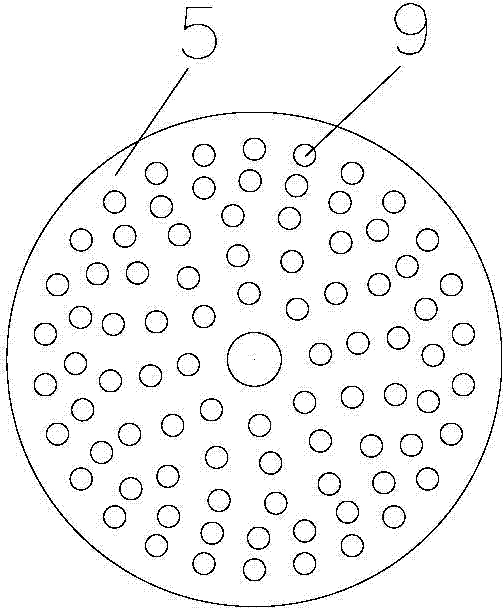

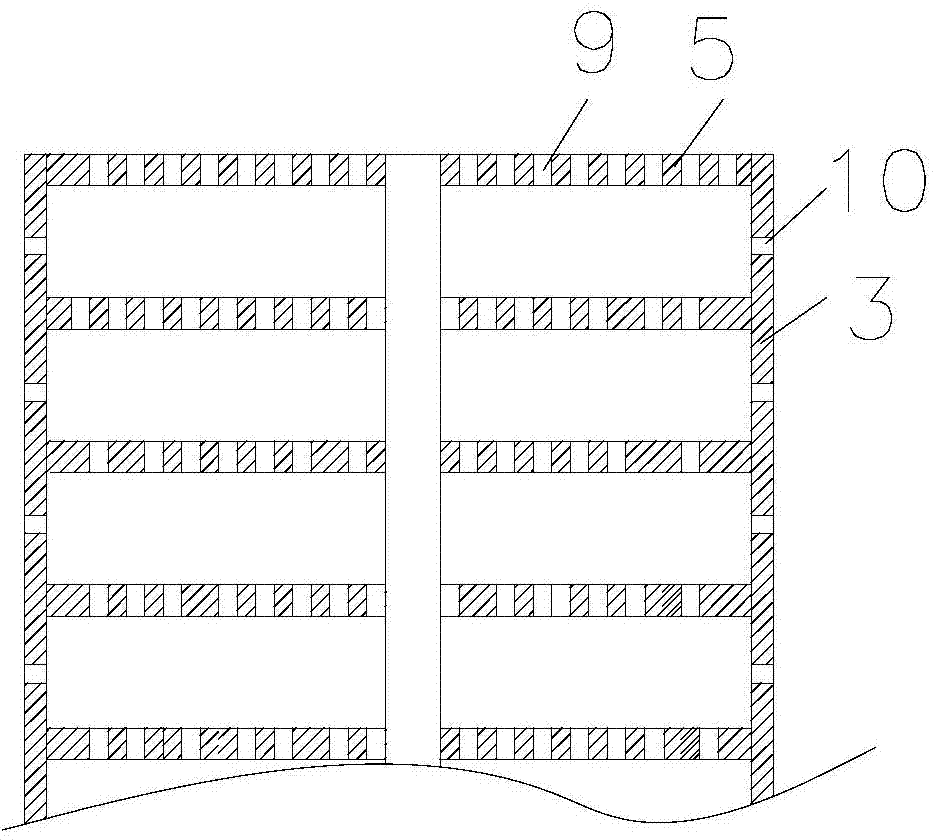

[0037] The exhaust pipe is set so that the hose 1 can be bent according to the needs during installation, and it can also reduce vibration. Installing the silencer device in the hose 1 greatly reduces the cost. After the airflow enters the hose 1, most of it will directly enter the silencer The pipe 3, through the second sound-absorbing board 5 arranged in layers, finally passes through the first sound-absorbing board 11 to decompose the airflow into countless weak and fine airflows, and another part of the airflow will enter the asbestos 2, and will pass through the asbestos 2 through the secondary silencing The through hole 10 enters the muffler pipe 3 and can also be decomposed into countless strands to achieve the purpose of silencing. The auxiliary muffler through hole 10 of the muff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com