Quick-to-disassemble/assemble type membrane drying device

A drying device and detachable technology, which is applied in the field of quick detachable membrane drying devices, can solve the problems of air pollution, maintenance difficulties, and reduced drying efficiency, and achieves improved quality, convenient operation, and increased space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

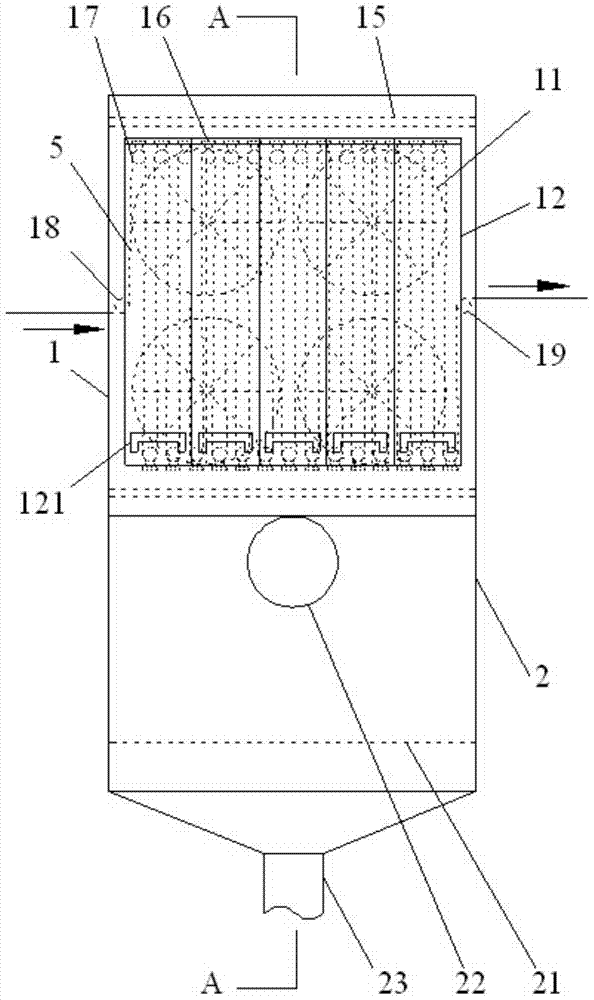

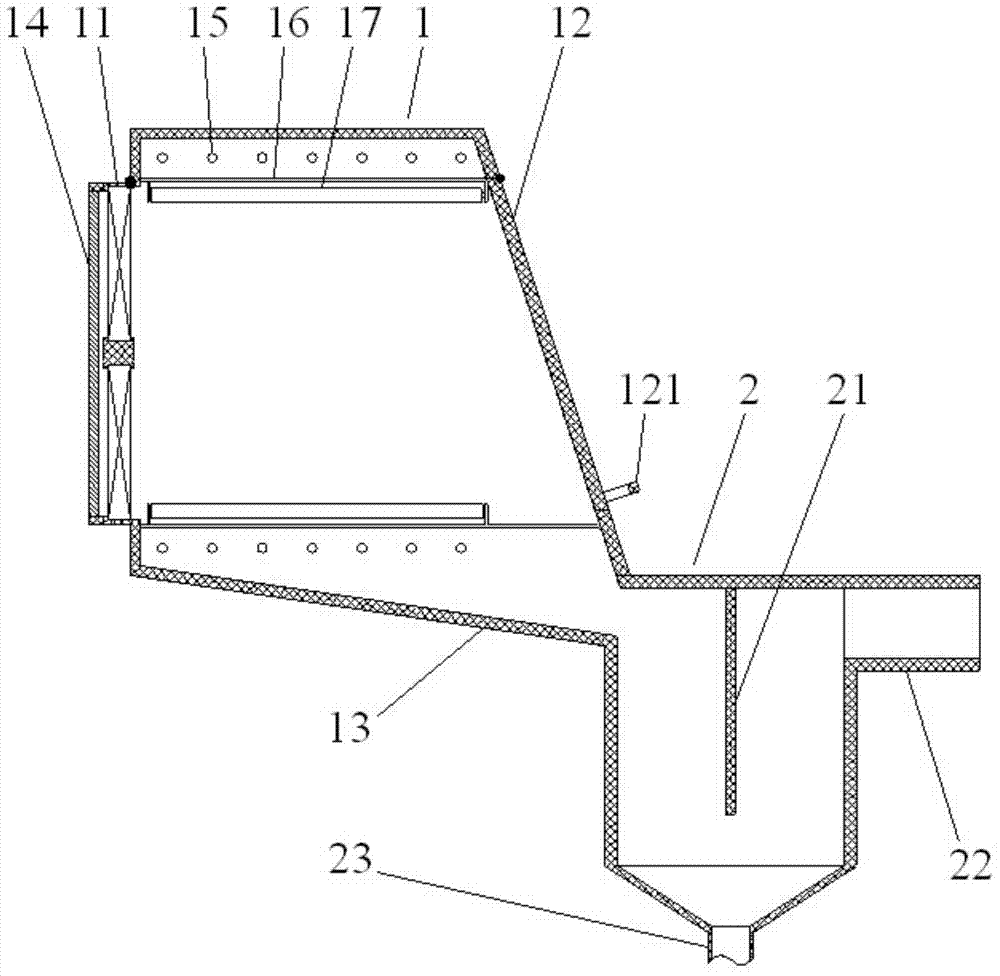

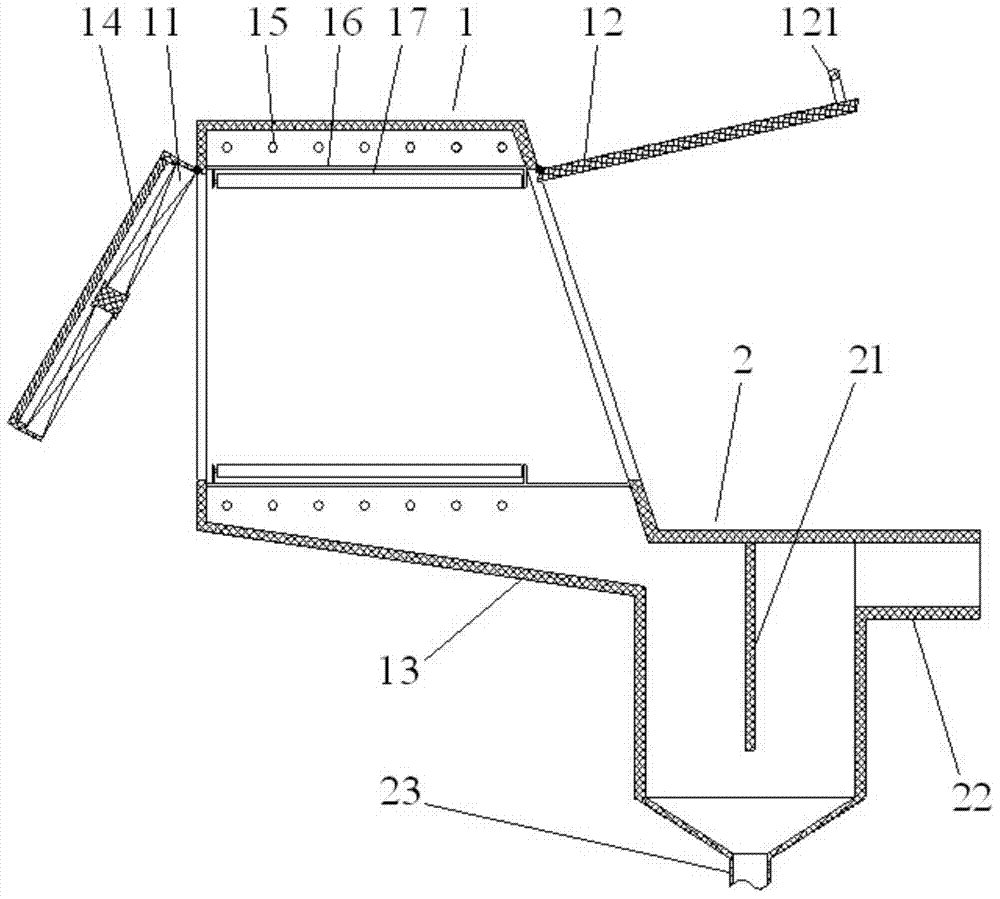

[0020] Such as figure 1 , figure 2 and image 3 As shown, the quick disassembly membrane drying device includes a drying box 1 and a waste discharge box 2; the drying box 1 and the waste discharge box 2 are integrally connected; and the waste discharge box One or more switchable condensation doors 12 are arranged on the side of the drying cabinet 1 connected to the body 2; the bottom surface of the drying cabinet 1 connected to the waste discharge cabinet 2 is set as a deflector 13; A plurality of fans 11 are arranged on the side opposite to the condensation door 12 on the dry box body 1; an air filter plate 14 is arranged on the outside of the fan; switch type; the top and bottom of the inside of the drying cabinet 1 are provided with a plurality of guide roller holders 16; the guide roller holders 16 are fixed with guide rollers 17; the guide roller holders 16 are connected with the drying box A plurality of heating pipes 15 are respectively arranged between the top and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com