Cable

A technology of cables and conductive cores, which is applied in the field of cables for transmitting analog signals and high-current power supplies. It can solve the problems of easy breakage, poor swing performance, and high conductor hardness, and achieve increased softness, improved swing performance, and high conductivity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

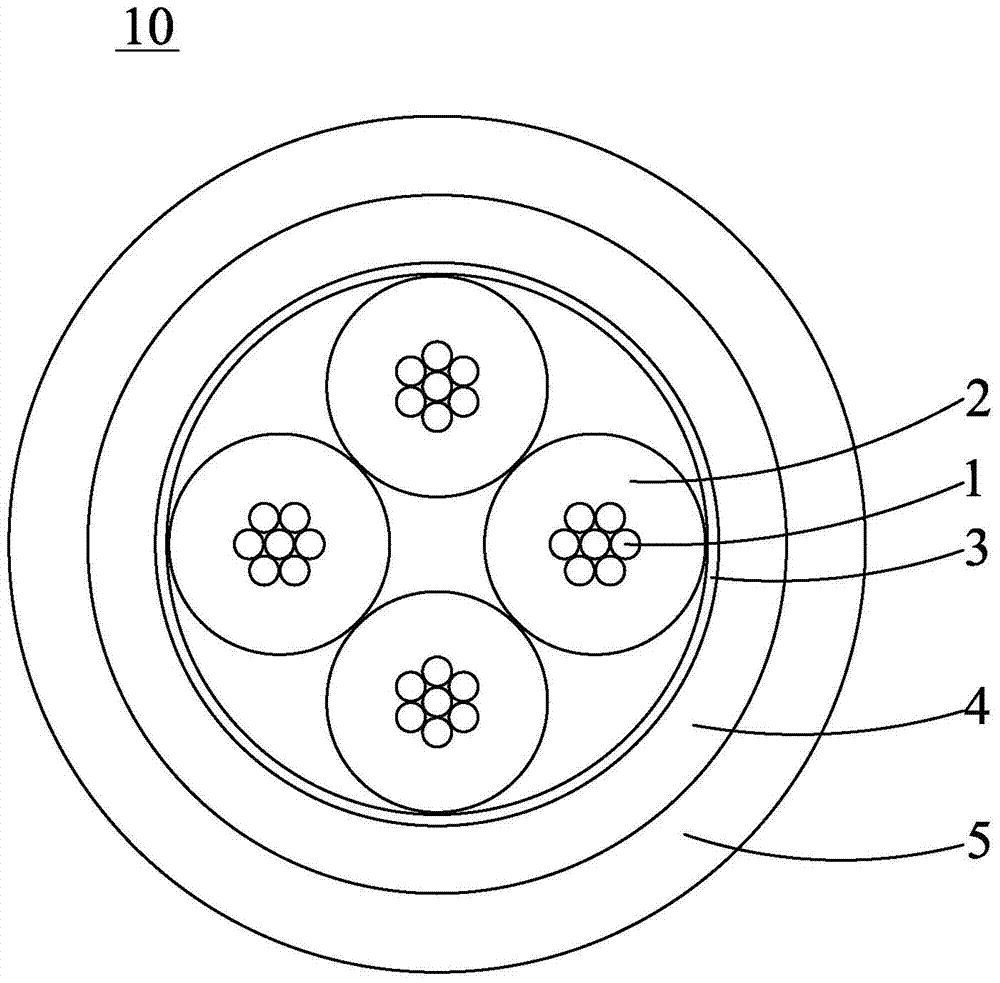

[0010] see figure 1 As shown, the cable 10 according to the first embodiment of the present invention includes several conductive core wires 1 twisted together, an insulator 2 wrapped outside the conductive core wire 1, insulating tissue paper 3 wrapped outside the insulator 2, wrapped in cotton The shielding layer 4 on the outside of the paper 3 and the insulating jacket 5 wrapped on the outermost side. The conductive core wire 1 is made of conductive fiber material, the conductive fiber is nano-scale, and its conductivity can be equal to that of a copper conductor. The conductive fiber has high softness, which increases the softness of the cable 10, and improves the performance of the cable. 10 texture, the conductive core wire 1 made of conductive fiber material also has relatively high conductivity. The shielding layer 3 is also made of conductive fiber material and has a mesh structure. The shielding layer 4 has a low surface resistivity, so that the cable 10 does not ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com