Preparation method for soft fabric with high air permeability

A breathable and fabric technology, applied in the field of fabrics, can solve the problems of short service life, fabric damage, high temperature injury of staff, etc., and achieve the effect of improving softness, softness and dyeing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

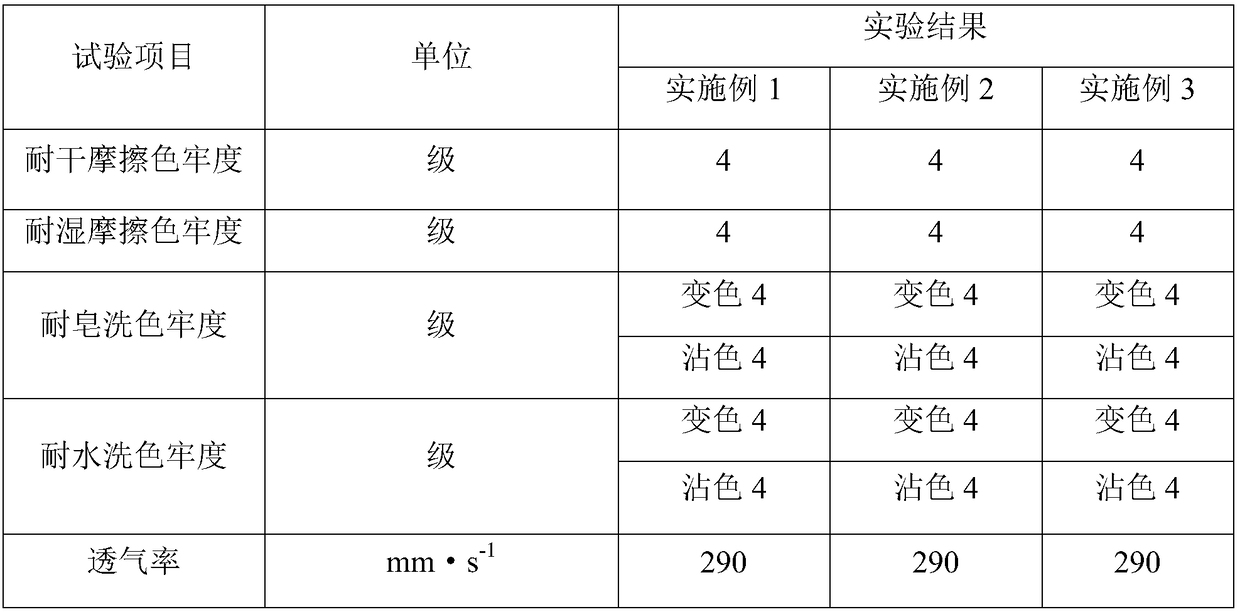

Embodiment 1

[0019] The preparation method of the soft fabric with high air permeability comprises the following steps: rinsing, dyeing, color fixing treatment, soaping, washing with water, drying and setting.

[0020] Wherein, the rinsing process is specifically as follows: the fabric is rinsed with a rinsing solution, the rinsing temperature is 60° C., the rinsing time is 30 minutes, and the rinsing solution includes the following components in terms of water volume: cutinase 6 g / L , sodium lauryl sulfate 6g / L.

[0021] The dyeing process is specifically as follows: the fabric is placed in a dyeing solution for dyeing, and the dyeing solution includes dyes, dyeing auxiliaries and water, wherein the dyeing auxiliaries include the following components in terms of water volume: chitosan 1g / L, keratin 3g / L, fatty alcohol polyoxyethylene ether 3g / L, the dyeing temperature is 50°C, and the dyeing time is 60min.

[0022] The color-fixing process is specifically as follows: a color-fixing liqu...

Embodiment 2

[0026] The preparation method of the soft fabric with high air permeability comprises the following steps: rinsing, dyeing, color fixing treatment, soaping, washing with water, drying and setting.

[0027] Wherein, the rinsing process is specifically as follows: the fabric is rinsed with a rinsing solution, the rinsing temperature is 65° C., the rinsing time is 35 minutes, and the rinsing solution includes the following components in terms of water volume: cutinase 7 g / L , sodium lauryl sulfate 7g / L.

[0028] The dyeing process is specifically as follows: the fabric is placed in a dyeing solution for dyeing, and the dyeing solution includes dyes, dyeing auxiliaries and water, wherein the dyeing auxiliaries include the following components in terms of water: chitosan 2g / L, keratin 4g / L, fatty alcohol polyoxyethylene ether 5g / L, the dyeing temperature is 55°C, and the dyeing time is 80min.

[0029] The color-fixing process is specifically as follows: the color-fixing liquid is...

Embodiment 3

[0033] The preparation method of the soft fabric with high air permeability comprises the following steps: rinsing, dyeing, color fixing treatment, soaping, washing with water, drying and setting.

[0034] Wherein, the rinsing process is specifically as follows: the fabric is rinsed with a rinsing solution, the rinsing temperature is 70°C, the rinsing time is 40min, and the rinsing solution includes the following components according to the water volume: cutinase 8g / L , sodium lauryl sulfate 8g / L.

[0035] The dyeing process is specifically as follows: the fabric is placed in a dyeing solution for dyeing, and the dyeing solution includes dyes, dyeing auxiliaries and water, wherein the dyeing auxiliaries include the following components in terms of water volume: chitosan 1 ~2g / L, keratin 4g / L, fatty alcohol polyoxyethylene ether 6g / L, the dyeing temperature is 60°C, and the dyeing time is 90min.

[0036] The color-fixing process is specifically as follows: the color-fixing liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com