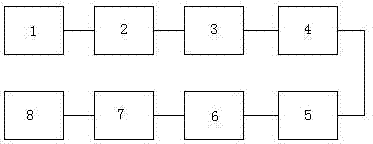

Intelligent and full-automatic motor rotor assembly line

A motor rotor, fully automatic technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of many processing and assembly procedures, low efficiency, and difficulty in hiring workers, and achieve the effect of reasonable structure, high efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

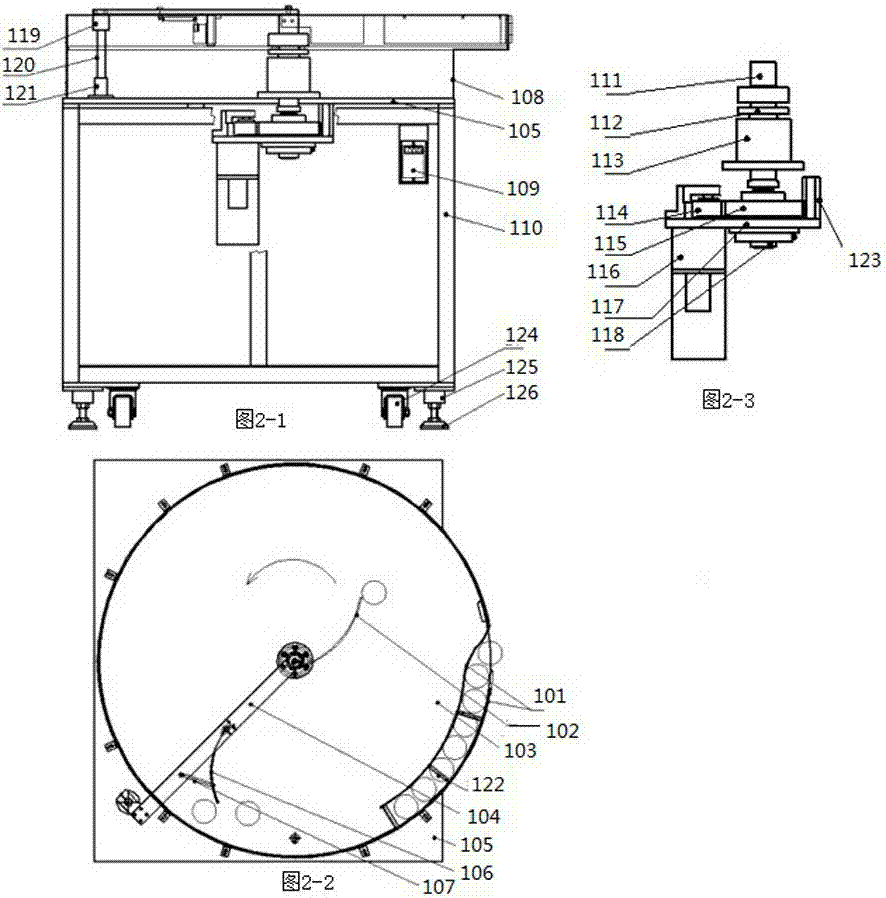

[0038] The rotor supply unit 1 is provided with a base plate 105 on which each component is installed. device 109, the bottom of the platform 110 is provided with casters 124 that can be easily moved and the platform feet 126 fixed by the connecting block 125; The outer periphery of the turntable is fixed on the support rotary table cover 108 on the platform base plate 105, and the discharge track 101 is connected and fixed to the support rotary table cover 108 by the support rod 122, and the support block 119, the pillar 120, the support 121 and the press The block 111 is connected and fixed on the supporting plate 104 on the platform base plate 105, the material shifting shrapnel 106 connected and installed by the tension spring 107 and the supporting plate 104, and the shifting material shrapnel 102 fixed on the pressing block 111; said turntable drive mechanism includes The bearing housing 113 fixed on the platform base plate 105, the transmission shaft 112 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com