Automobile cooling liquid waste heat recycling device

A waste heat recovery and automobile cooling technology, applied in the direction of electrical components, engine components, machines/engines, etc., to achieve the effects of energy saving, strong practicability, and strong structural design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

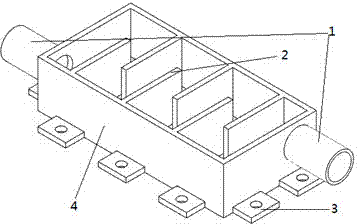

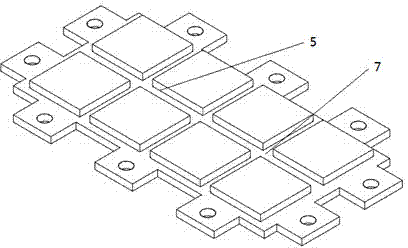

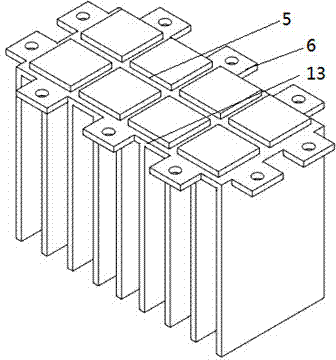

[0016] A device for recovering waste heat from automobile coolant, comprising a liquid storage tank 4 , a thermoelectric power generation module 5 , a radiator 13 and a thermal insulation pad 7 . The liquid storage tank is used to collect the heat of the engine coolant, and a water inlet and a water outlet are respectively arranged on its left and right sides, and the liquid storage tank is connected in series with the engine cooling water circuit 1 through the water inlet and the water outlet. Inside the liquid storage tank, there is a fin plate 2 used to collect the heat of the engine coolant. There are 6 fin plates in the same shape, which are used to collect the heat of the engine coolant, which is beneficial to the uniform temperature distribution at the bottom of the liquid storage tank and ensures that the liquid storage tank There is enough heat on the bottom to provide a heat source for the unit. The radiator 13 includes a main cooling fin 11 and a heat dissipation fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com