Multitubular gasification reactor

A gasification reactor, tube-and-tube technology, which is applied in the chemical reaction reactor of gas and solid (its boiling point is lower than 700°C), in the field of tube-and-tube gasification reactor, which can solve the problem of uneven heating and affecting the reaction In order to achieve the effects of enhanced heat transfer, avoiding catalyst deactivation and burning, and easy control of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

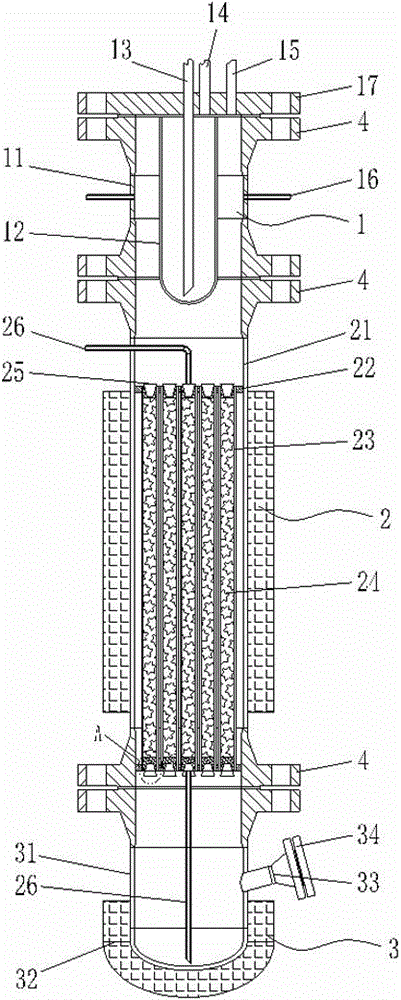

[0028] Embodiment one: if Figure 1~2 As shown, a tube-and-tube gasification reactor includes an interception section 1, a reaction section 2, and a gasification mixing section 3 that are sequentially connected from top to bottom;

[0029] The retaining section 1 includes a first sleeve 11, flanges 4 are provided at both ends of the first sleeve 11, and a blind plate 17 is connected to the top flange of the first sleeve 11. The first sleeve 11 is provided with an inner tank 12 with a U-shaped longitudinal section, the top opening of the inner tank 12 is sealed and connected with the bottom of the blind plate 17, and the blind plate 17 is provided with two air outlet pipes communicating with the inner tank. 13 and an air inlet pipe 14, the two opposite side walls of the first sleeve are provided with air outlets 16;

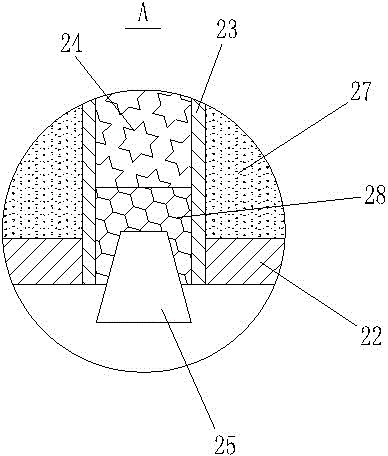

[0030] The reaction section 2 includes a second sleeve 21, flanges 4 are arranged at both ends of the second sleeve 21, and several vertical tubes 23 are evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com