A bearing height detection device

A height detection device and bearing technology, which is applied in sorting and other directions, can solve the problems of inaccurate bearing height detection and easy wear of the detection head, and achieve the effects of high automation, high work efficiency and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

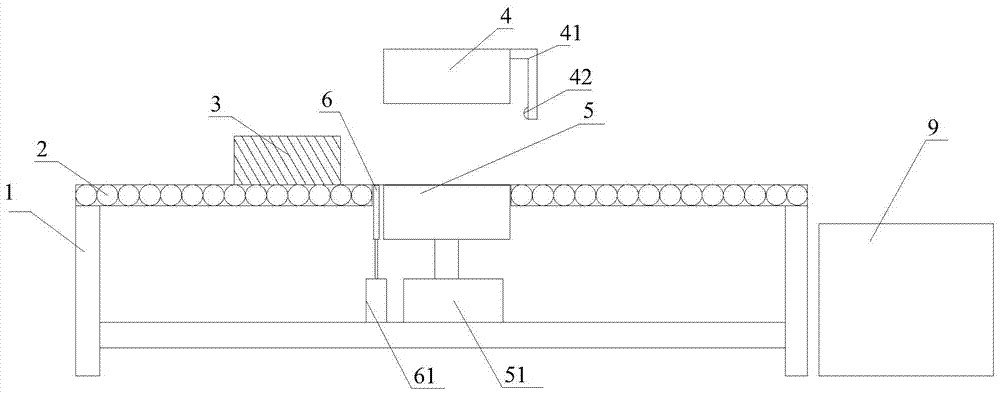

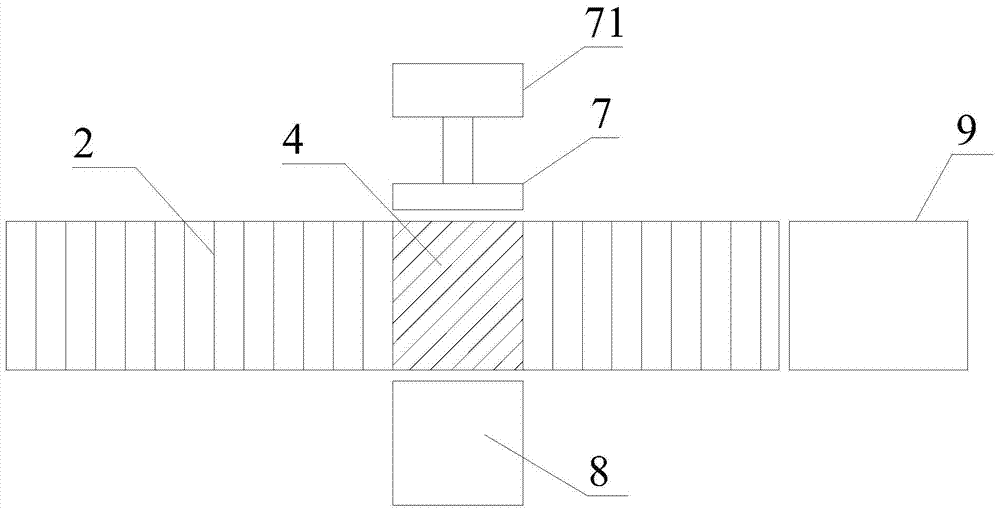

[0017] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a bearing height detection device proposed by the present invention; figure 2 It is a top view of a bearing height detection device proposed by the present invention.

[0018] refer to figure 1 , figure 2 , a bearing height detection device proposed by the present invention is used to detect the height of the bearing 3, including a bracket 1, a controller, a limit plate 4, a lifting platform 5, a baffle plate 6, a push plate 7, a first driving device 51, The second driving device 71 , the third driving device 61 , the first receiving box 8 , and the second receiving box 9 .

[0019] Lifting platform 5 is installed on support 1, and the second receiving box 9 is arranged at the discharge port place of support, is all provided with conveying roller group 2 between lifting platform and support feeding end, discharging end, and setting limit is limited above lifting platform. Position plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com