Coal fired boiler belt conveying type coal quantity weighing metering device

A technology for belt conveying and coal-fired boilers, which is applied to measuring devices, conveyor objects, transportation and packaging, etc., can solve problems such as easy errors and unsustainable scale accuracy, and achieve the effect of reducing labor burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

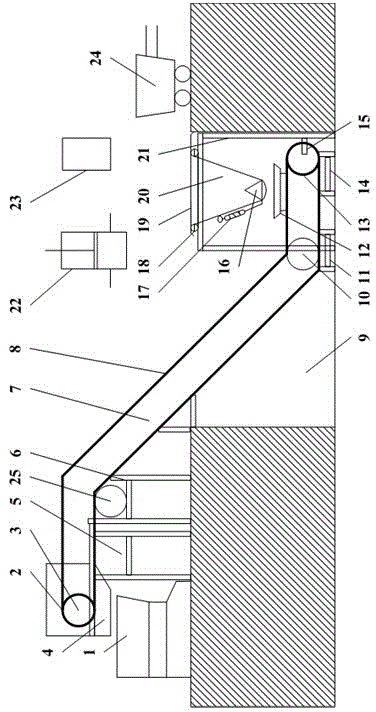

[0019] Such as figure 1 Shown, the present invention comprises belt transport device, weighing coal scuttle 20 and metering control cabinet 23; Weighing coal scuttle 20 is housed in coal unloading pit 9, and weighing coal scuttle 20 is installed on the side of coal unloading pit 9 by fixed support 21 At the front, the coal truck 24 is located on the ground outside the coal unloading pit 9, and the coal of the coal truck 24 is poured into the weighing coal hopper 20, and the boiler coal hopper 1 is located on the ground on the other side outside the coal unloading pit 9, weighing A belt transport device for transporting coal is installed between the heavy coal hopper 20 and the boiler coal hopper 1; a weighing sensor 18 for measuring the weight of the weighing coal hopper 20 is installed on the weighing coal hopper 20, and the weighing sensor 18 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com