a traction machine

A machine base and rotor technology, applied in the field of traction machines, can solve problems such as the increase of traction machine parts, elevator vibration and noise, and inertia increase, and achieve the effects of saving manual installation, improving safety and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

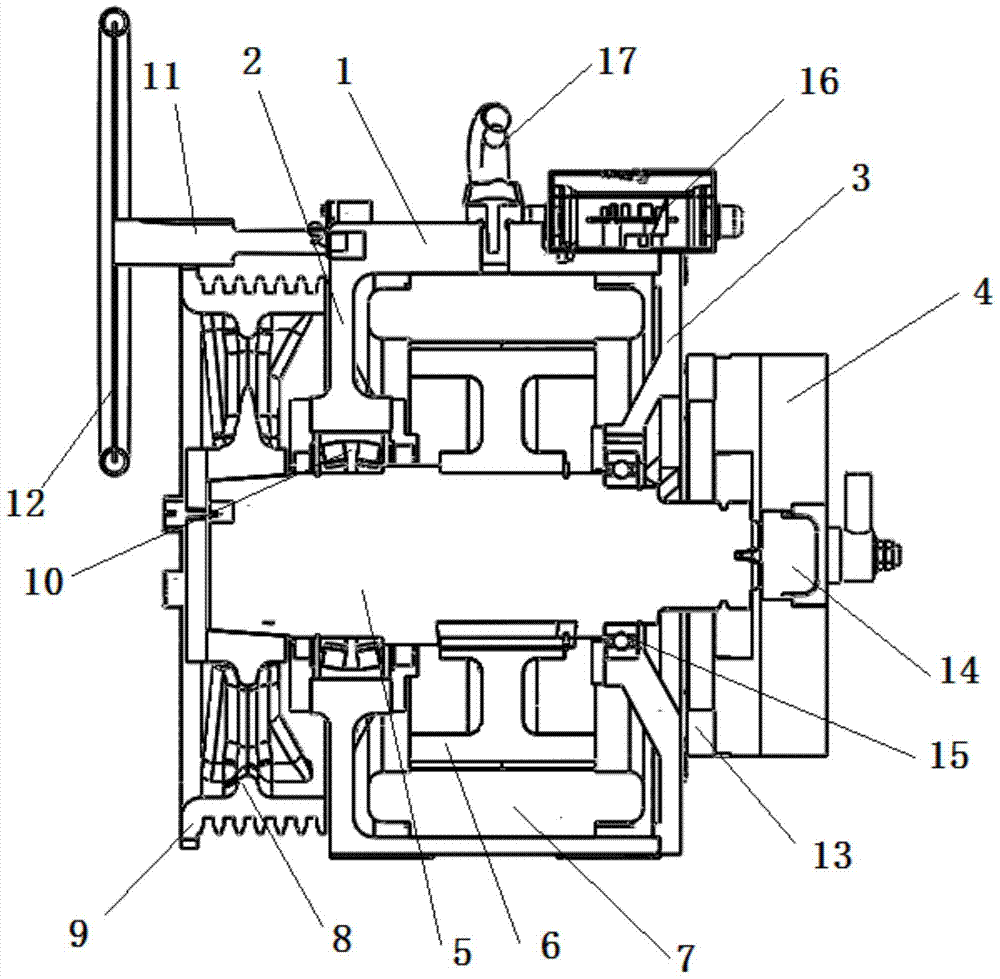

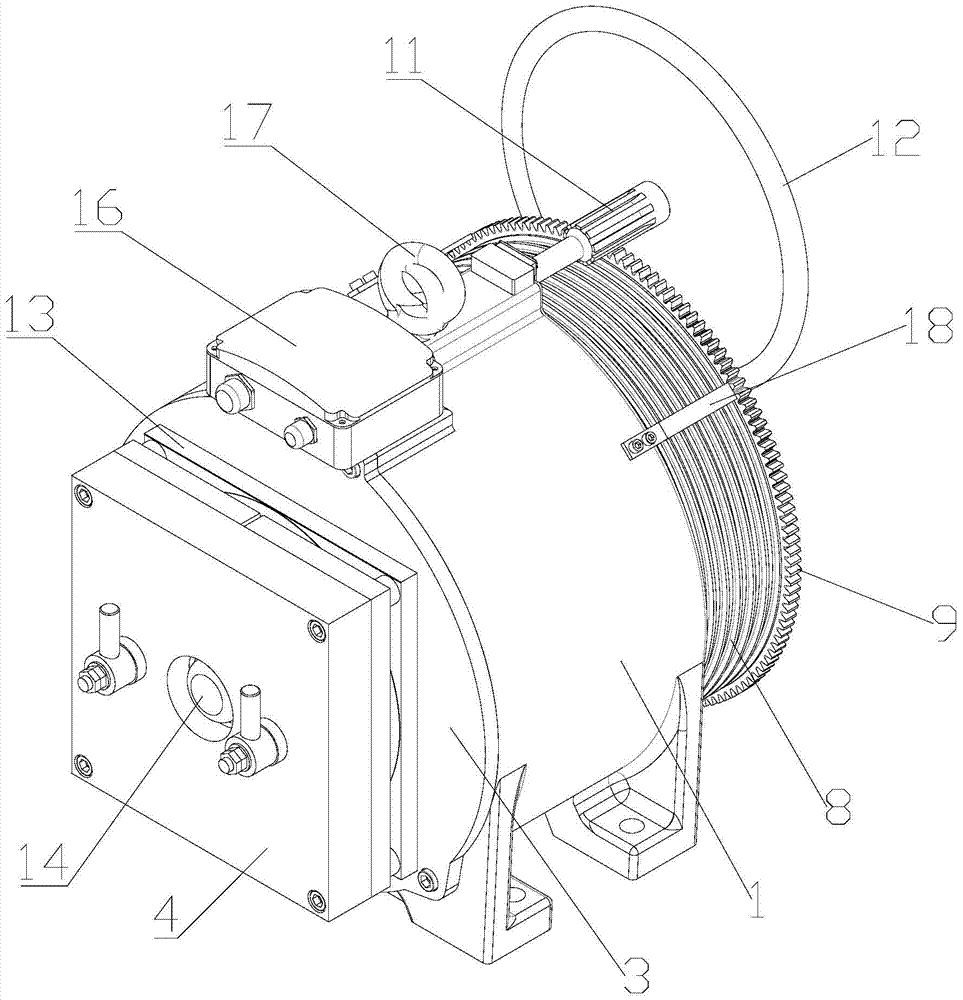

[0028] Such as figure 1 The traction machine described in the present invention is shown, such as figure 2 As shown, including machine base 1, one end of said machine base 1 is integrally formed with side cover 2, said machine base 1 and side cover 2 are preferably made of seamless steel, which can effectively ensure the overall structure of the traction machine stability, and is conducive to long-term use, the other end is fixedly installed with a brake disc end cover 3, and a stator 7 is fixedly installed in the base 1, and the stator 7 is preferably a stator core with windings, and the stator 7 is equipped with a rotatable rotor assembly;

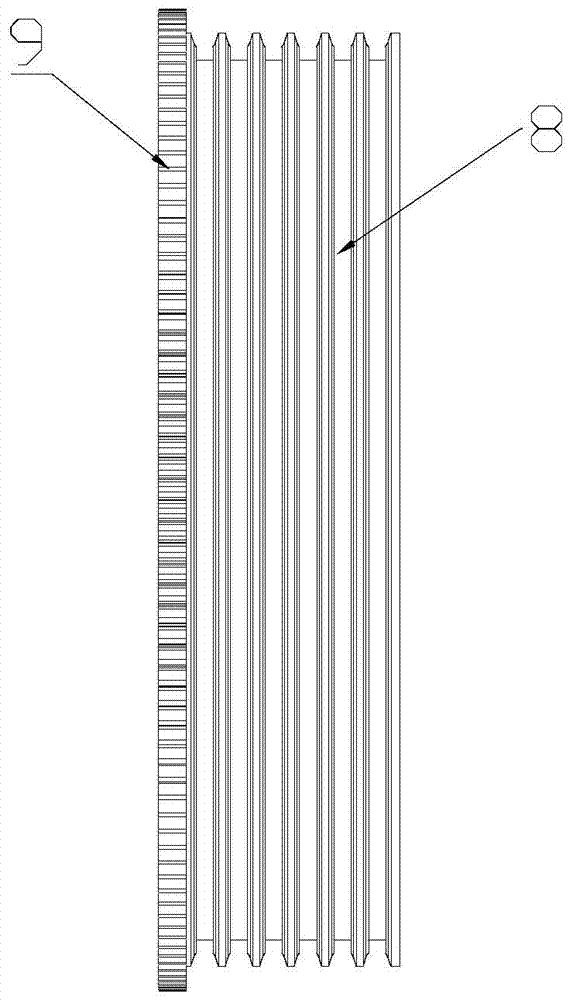

[0029] The rotor assembly includes a shaft 5 and a rotor yoke 6, such as Figure 5 As shown, the rotating shaft 5 is statically connected to the inner wall of the rotor yoke 6 through a flat key 21, and a plurality of arc-shaped magnets 19 are uniformly glued on the outer wall of the rotor yoke 6, and the arc-shaped magnets 19 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com