Electrophoresis conveying device

A conveying device and electrophoresis technology, applied in electrophoretic plating, transportation and packaging, electrolytic coatings, etc., can solve the problems of not meeting the production rhythm and low work efficiency, and achieve the effects of improving the production takt, simple structure and preventing tilting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

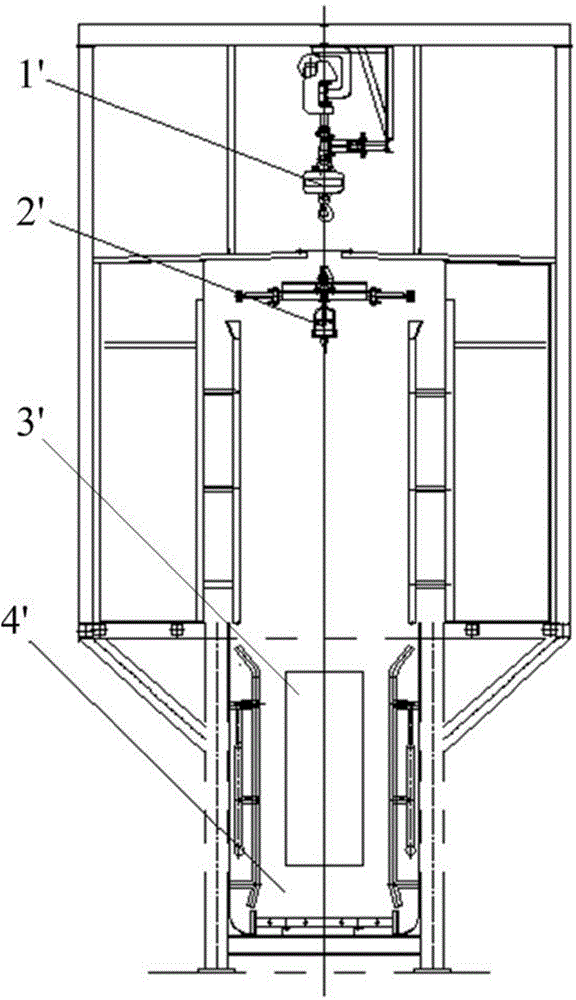

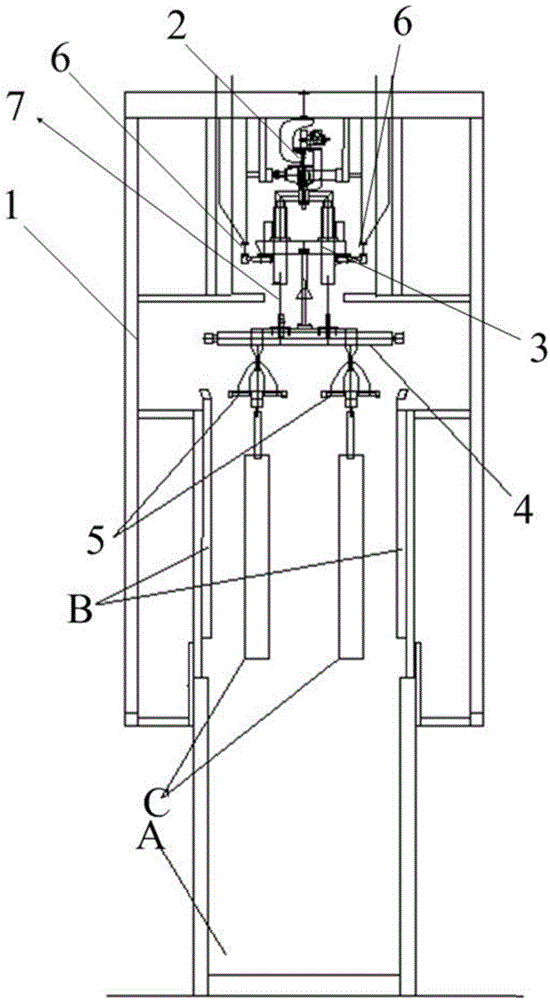

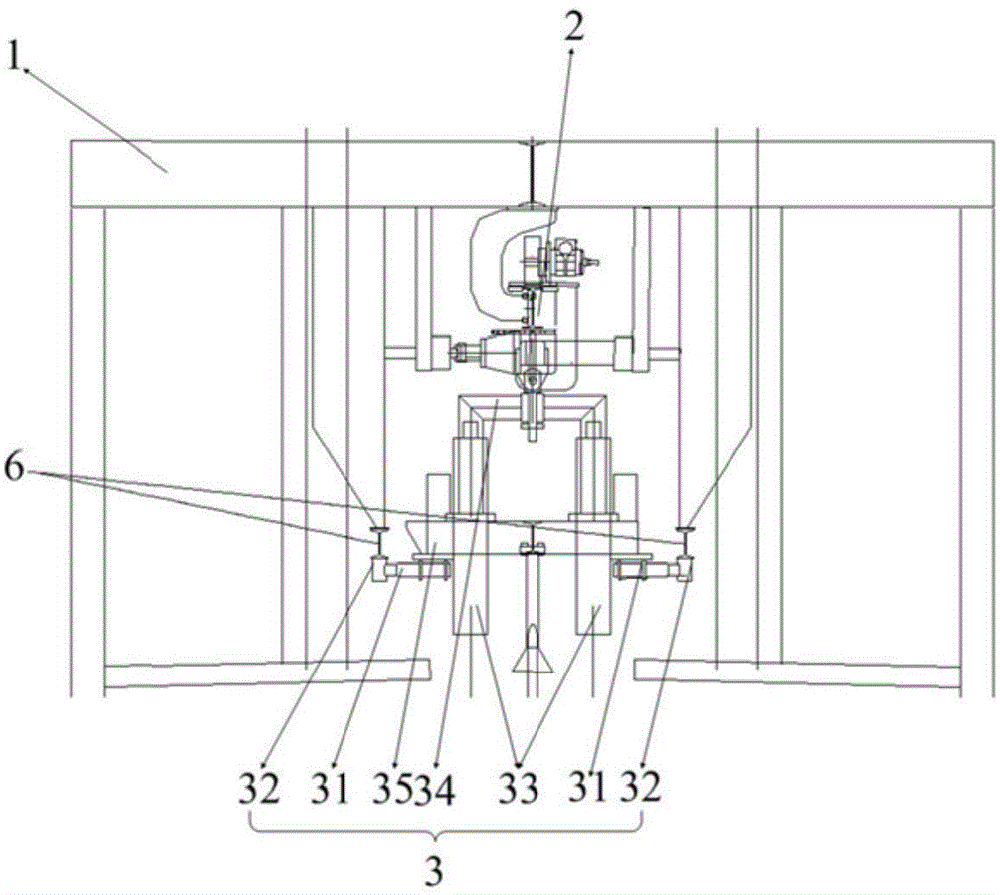

[0034] refer to figure 2 and image 3 , the electrophoretic transport device provided by the present invention includes a fixed frame 1, the top of the fixed frame 1 is fixed with a drive part 2, and the drive part 2 can be a drive motor, an electric hoist and other devices. In order to facilitate the installation of the spreader, the The lower end of the driving part 2 is fixedly connected with a articulated part 3, and the articulated part 3 is connected with a sling, and the sling includes an upper sling 4 and a lower sling 5, wherein the lower sling 5 is used for hanging Hang the electrophoresis part C, the upper spreader 4 is used to arrange and fix the lower spreader 5, and at least two sets of the lower spreaders 5 are fixed on the upper spreader 4, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com