Preparation method of variable-thickness layer-to-layer connection structure fabric

A layered structure and variable thickness technology, applied in the direction of fabrics, braids, textiles, etc., can solve the problems that cannot be carried out internally, and the fabric's anti-delamination effect is poor, so as to achieve the increase of inter-layer connection depth and strength, and anti-delamination Strong ability and good anti-delamination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of the new structural layered fabric formed by the mutual transfer of the inner and outer yarn bundles, and the design of the fabric process parameters are shown in Table 1.

[0046] Table 1 Process parameters of layered fabric

[0047]

[0048]The specific operation method is as follows:

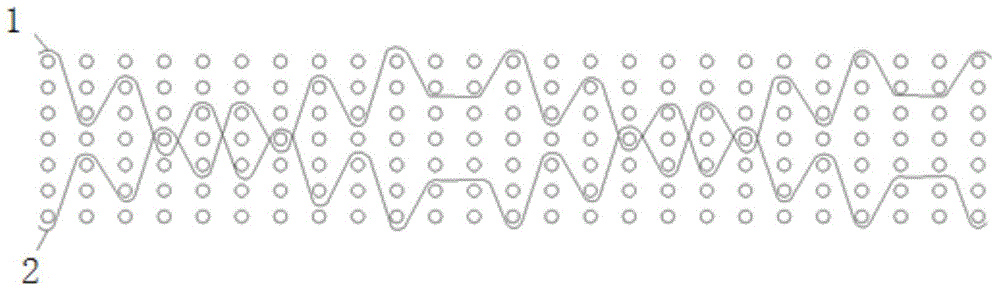

[0049] (1) Layered fabrics are interwoven by warp and weft direction yarn bundles through the relative displacement and weft threading of two adjacent rows of warp yarns, see Figure 4 . Set two adjacent columns of warp yarns as a pair, and define the column where the warp yarns can be seen on the outer surface of the fabric as the high column. Figure 4 The column ① in the column, the other column that is paired with it is the lower column, that is Figure 4 ② in the column, and the distance between the high and low columns is 2 spindles.

[0050] (2) The first layer is opened, and the weft yarn is introduced, and then the second layer is opened, and the weft ...

Embodiment 2

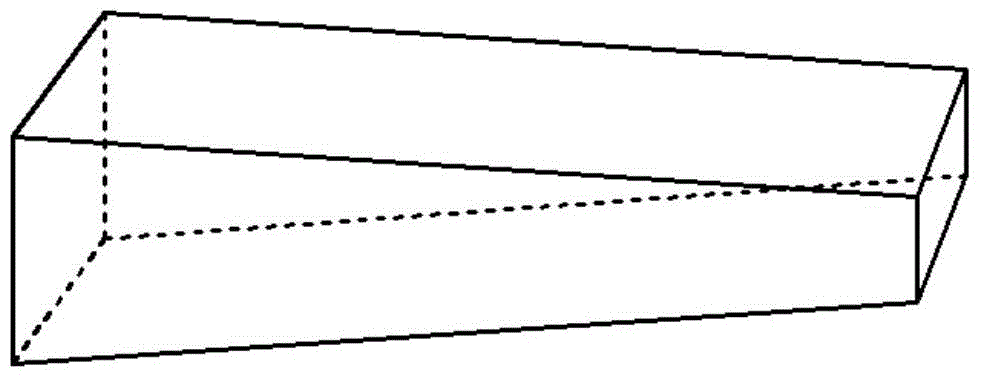

[0057] developed as figure 2 For the plate-shaped variable-thickness fabric shown, the thickness of the plate gradually changes from 8mm to 5mm, and the process parameters of the plate-shaped variable-thickness layered fabric are designed as shown in Table 2.

[0058] Table 2 Process parameters of panel fabric with variable thickness layered structure

[0059]

[0060]

[0061] The specific operation method is as follows:

[0062] (1) Set two adjacent rows of warp yarns as a pair, and define the row where the warp yarns can be seen on the outer surface of the fabric as the high row, that is, Figure 4 The column ① in the column, the other column that is paired with it is the lower column, that is Figure 4 ② in the column, and the distance between the high and low columns is 2 spindles.

[0063] (2) The first layer is opened, and the weft yarn is introduced, and then the second layer is opened, and the weft yarn is introduced, and so on, and the weft yarn is inserted...

Embodiment 3

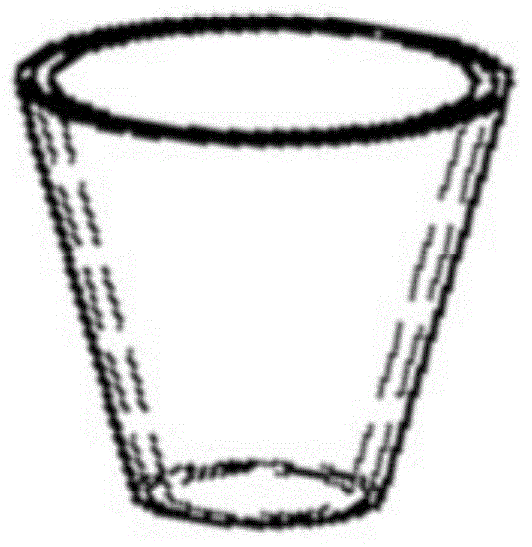

[0070] developed as image 3 The tapered tubular variable thickness fabric shown in Table 3 shows its technological parameter design.

[0071] Table 3 Process parameters of tapered tubular fabric with variable thickness

[0072]

[0073] The tapered tubular variable-thickness fabric has a total of 120 wefts, and two rows of warp yarns total 30. It needs to be reduced 60 times from 3 strands to 1 strand. Therefore, one warp yarn is subtracted for every two wefts.

[0074] Its specific operation is as follows:

[0075] (1) Set two adjacent rows of warp yarns as a pair, and define the row where the warp yarns can be seen on the outer surface of the fabric as the high row. Figure 10 The column ① in the column, the other column that is paired with it is the lower column, that is Figure 10 ② in the column, and the distance between the high and low columns is 2 spindles.

[0076] (2) The first layer is opened, and the weft yarn is introduced, and then the second layer is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com