High-rise building basement roof settlement post-pouring joint advanced water stop construction method

A technology for basement roofs and high-rise buildings, which is applied in construction, water conservancy projects, artificial islands, etc., to achieve continuous and complete waterproofing and facilitate site layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the embodiment given with accompanying drawing, but embodiment does not constitute any limitation to the present invention.

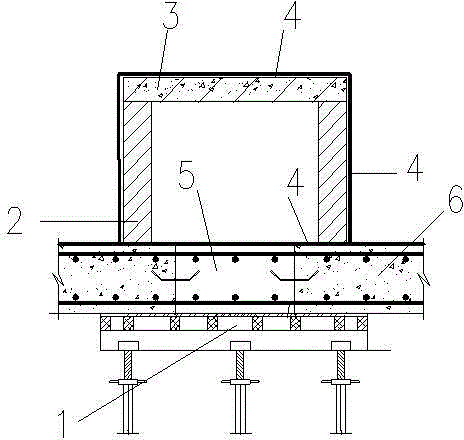

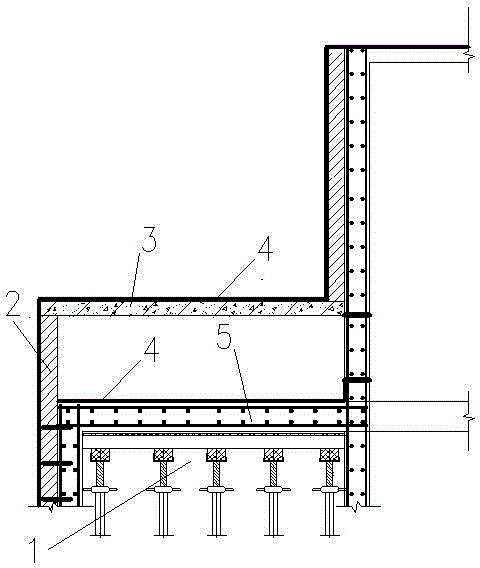

[0031] see figure 1 , figure 2 , a kind of construction method of advanced water-stop pouring belt after the settlement of the basement roof of high-rise building, it is carried out according to the following steps:

[0032] (1) Clean up both sides of the cast belt 5 after settlement.

[0033] (2) The lower supporting formwork and post-casting belt support system 1 of the post-settlement pouring belt 5; the post-casting belt support system 1 adopts f48*3.0 steel pipe scaffolding, and the vertical and horizontal spacing of the vertical poles is 800mm.

[0034] (3) Waterproof both sides of the cast belt 5 after settlement.

[0035] (4) Build waterproof guide wall 2 on both sides of the upper part of pouring belt 5 after settlement, formwork and tie bars on the upper part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com