The nut-turn-screw shift-tight locking device installed in the undermount sink

A screw and sink technology, used in water supply installations, indoor sanitary piping installations, kitchen cabinets, etc., can solve the problems of cabinet table area water, inconvenient installation, easy breakage, etc., and achieves large contact area, small footprint, assembly and disassembly. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

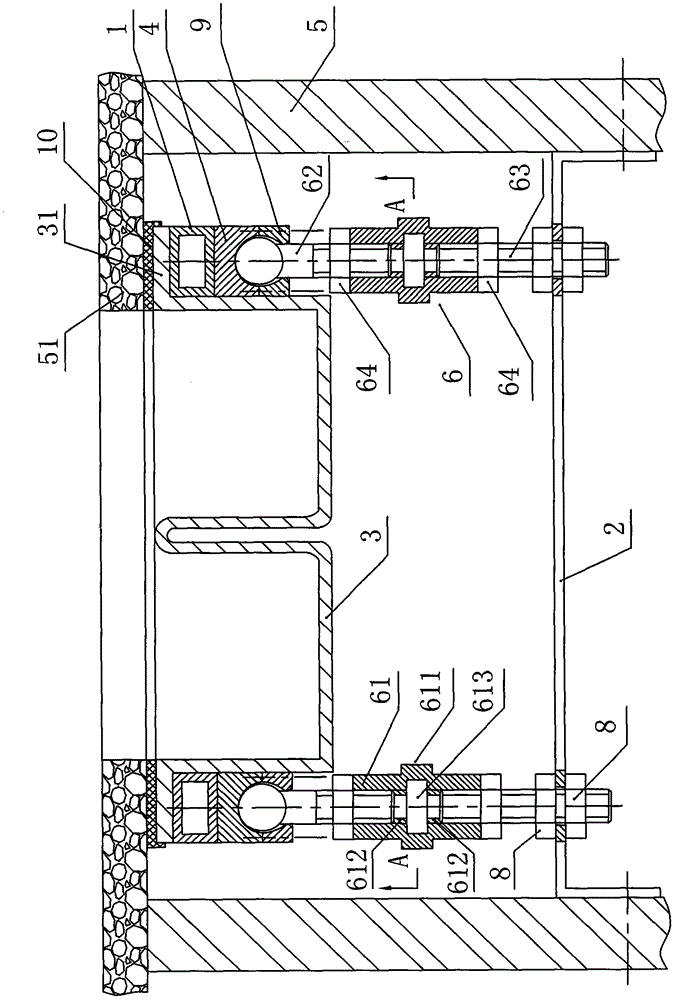

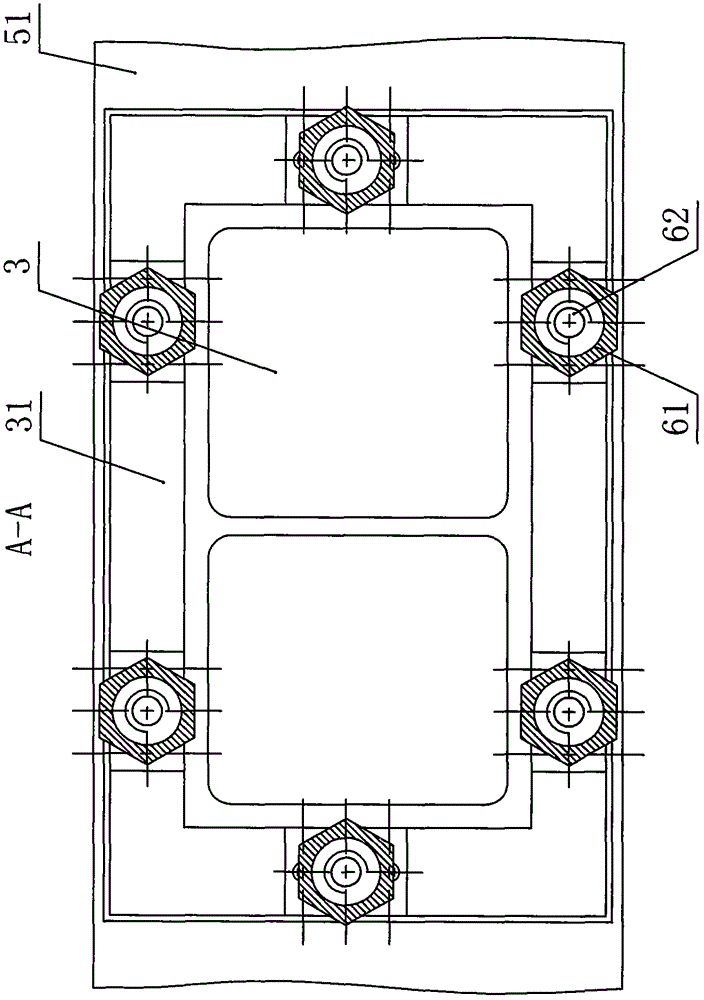

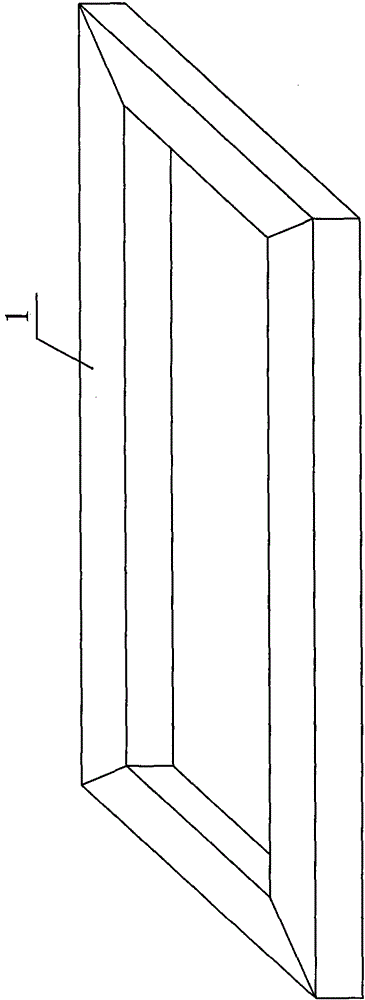

[0015] Such as figure 1 , 2 , 3, 4, and 5, the present invention discloses a nut-turn-screw shifting and locking device installed in an undermount sink, including a compression frame 1, a compression block 4, a connection block 9, and a compound screw adjustment mechanism 6 and the frame 2, the compression frame 1 is attached to the lower surface of the sink edge 31, the compression block 4 is in contact with the lower end surface of the compression frame 1, and the frame 2 is installed on the cabinet body 5, the compound screw adjustment mechanism 6 is arranged between the compression block 4 and the frame 2, and the connection block 9 connects the compound screw adjustment mechanism 6 and the compression block 4 together, and the connection Block 9 and pressing block 4 are fixed by screws. With the above-mentioned technical solution, since the pressing frame 1 is bonded to the peripheral edge 31 of the water tank, the contact area is large and the stress is small. The fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com