Method for achieving ground coal bed gas production through cluster well and horizontal well under complex terrain condition

A complex terrain, cluster well technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high cost, low output, difficult construction, etc., to achieve good economy and increase coal seam The scope of gas surface mining, the effect of saving coalbed methane surface development projects and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

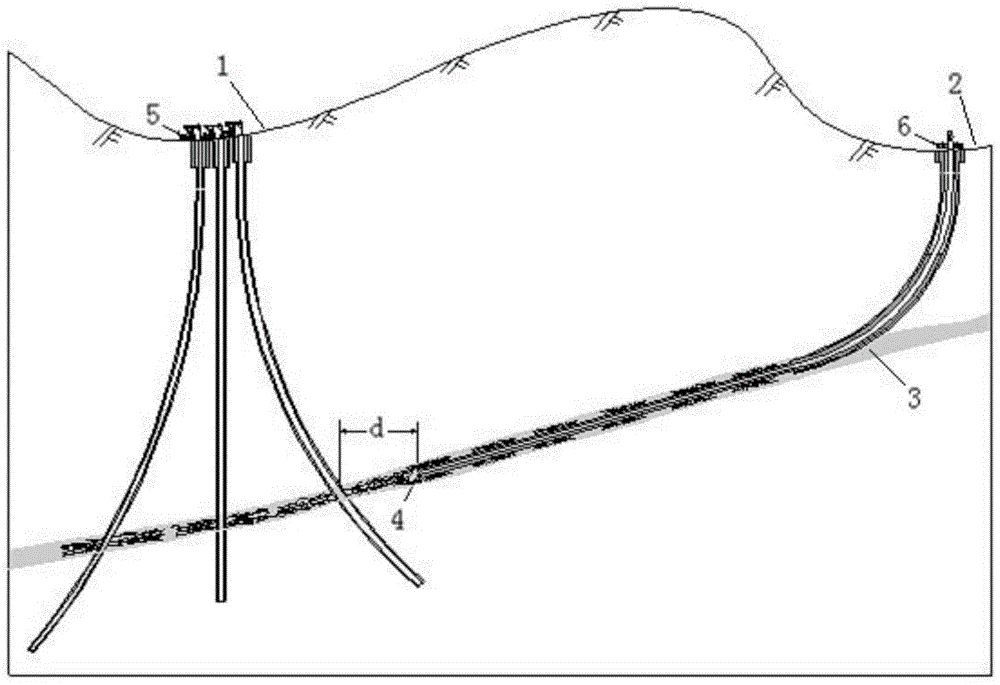

[0020] Such as figure 1 As shown, the combined ground mining method of coalbed methane by cluster wells and horizontal wells under complex terrain conditions of the present invention comprises the following steps:

[0021] (a) Set up a cluster well site (1) meeting the ground construction conditions at the position where the depth of the target coal seam (3) is 600m to 800m, construct a cluster well and cement the well; in this step, the cluster well consists of a vertical well and Composed of four to five directional wells, both vertical wells and directional wells adopt a double-opening shaft structure. The maximum well deviation of directional wells is less than 45° and the build-up rate is less than 5° / 30m. The plane distance between vertical wells and directional wells is controlled at 250m~ 300m, in order to reduce the difficulty of cluster well construction and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com