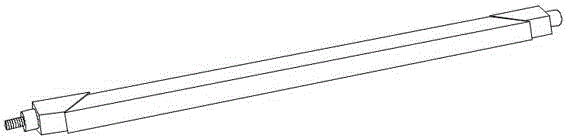

Locking strip for vertical mounting

A technology of vertical installation and locking strips, applied in the direction of friction-clamped detachable fasteners, connecting components, mechanical equipment, etc. Long thread locking length, outstanding substantive features, and the effect of preventing dislocation and overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

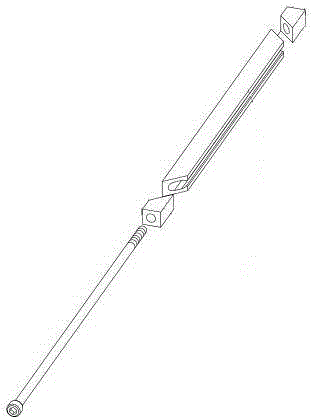

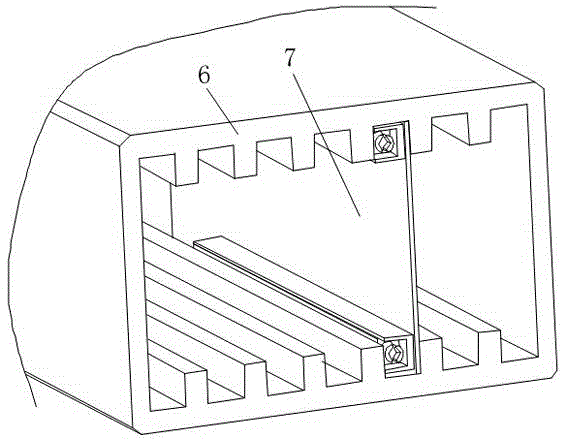

[0041] Such as image 3As shown, the locking strip for vertical installation is mainly used for the clamping installation of the chassis 6 and board 7 of military equipment, especially the clamping installation during vertical insertion, and is usually installed in the preset installation groove of the chassis. The locking bar is used to clamp the board to keep it stably in the chassis. When the board fails or needs maintenance, just adjust and loosen the locking bar to take off the board. Due to the design defect of the existing locking bar structure, if the power tool is used to disassemble, it is easy to cause the end wedge to fall, which will cause the short circuit of the board card circuit to fail, and when the locking bar is inserted and pulled in the vertical direction, it will be damaged due to gravity. The function makes the wedge part open at the maximum width, which seriously affects the insertion of the board and greatly increases the difficulty of board insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com