Air conditioner outdoor unit shell manufacturing method

A production method and technology for an air conditioner external unit, which are applied in the directions of air conditioning system, heating method, space heating and ventilation, etc., can solve the problems of difficulty in guaranteeing strength, breaking the paint layer of the panel, and increasing the number of assemblers in the production line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in further detail below through specific examples, but the present invention is not limited only to the following examples.

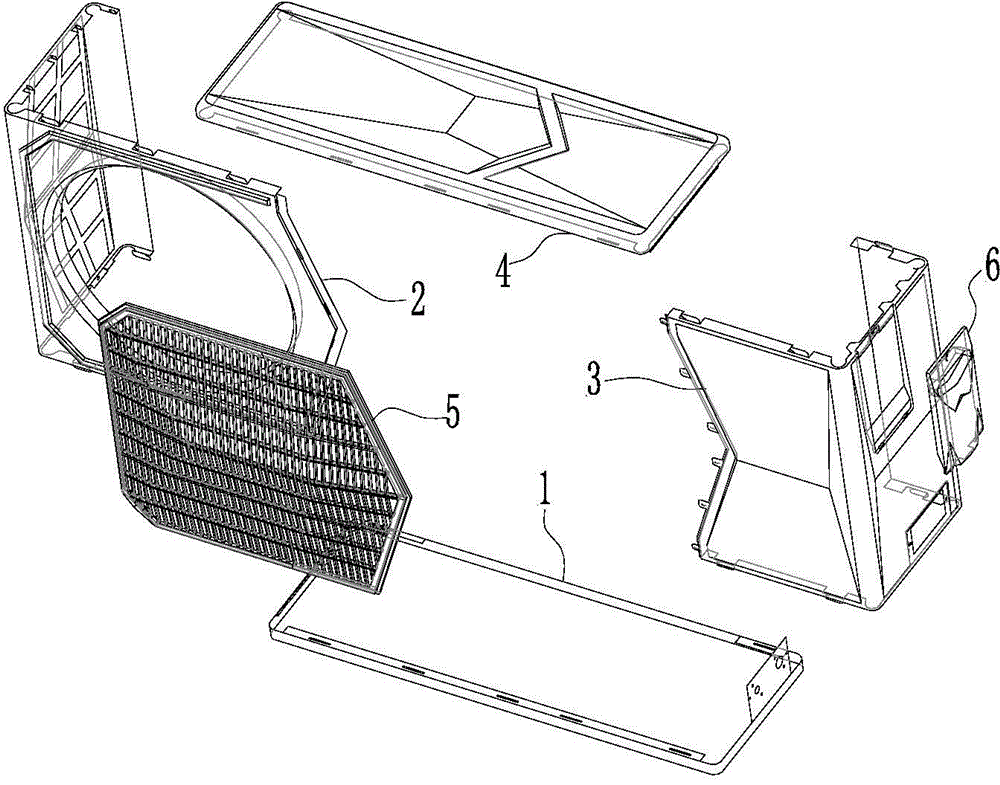

[0042] A method for manufacturing an air-conditioner outer unit casing according to the present invention includes the following steps: first step: first make the chassis 1, the left front panel 2, the right front panel 3, and the top cover 4 respectively; wherein the left front panel 2 includes the left front panel body and a The left side panel formed by side bending, the right front panel 3 includes the right front panel body and one side bent to form the right side panel, one side of the left front panel body is buckled with one side of the right front panel body to form the front panel of the housing;

[0043] Step 2: Fasten the chassis 1, the left front panel 2, the right front panel 3, and the top cover 4 with each other and fix them with screws.

[0044] Fold the other side of the left side panel to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com