Ejecting oil scavenger of flooded evaporator for screw water chiller

A flooded evaporator and chiller technology, which is used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reduced heat exchange effect of the evaporator, failure to work normally, and excessive oil loss of the compressor. Flexibility, improved use efficiency, improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

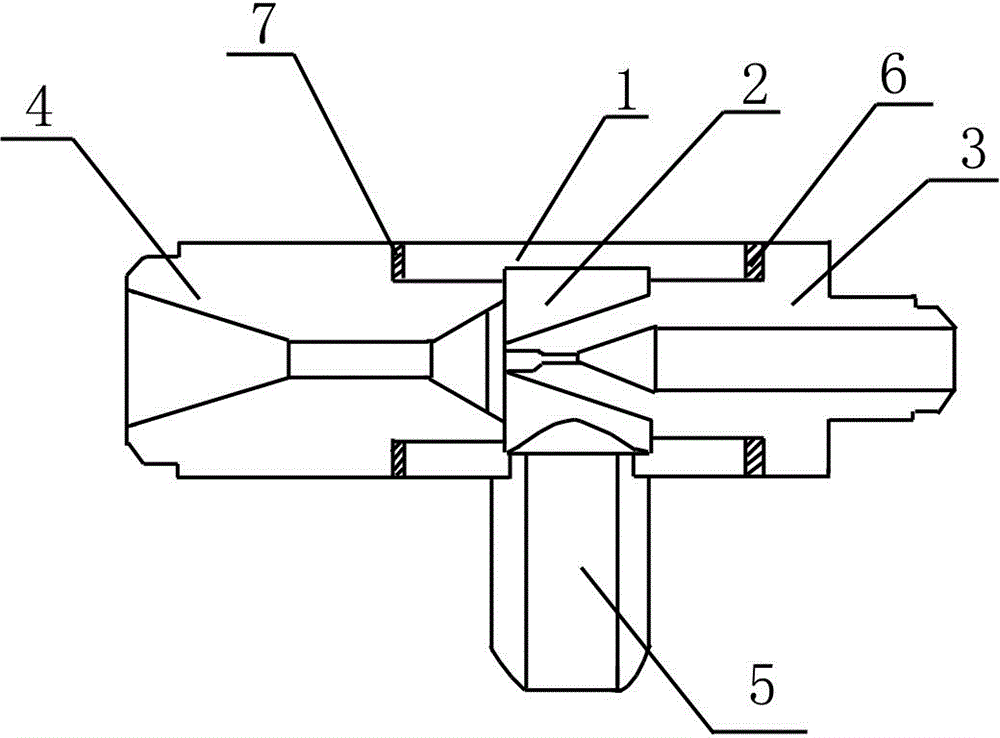

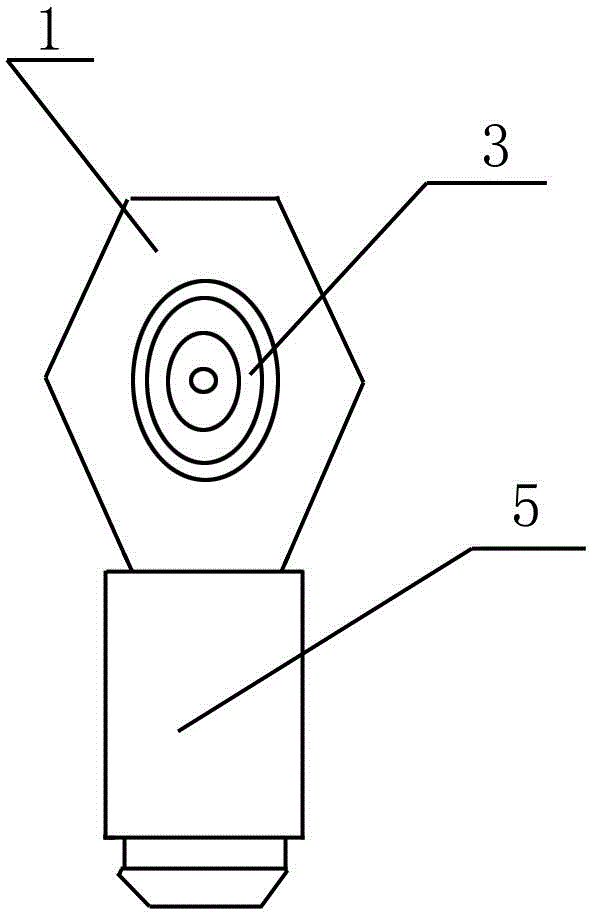

[0009] exist figure 1 and figure 2 Among them, the present invention provides a flooded evaporator injection oil return device of a screw chiller, which includes a base 1, a cavity 2 is provided in the base 1, and the front and rear parts of the base 1 are respectively connected to There are a nozzle 3 and a mixing tube 4, the front part of the base 1 is threaded with the nozzle 3, and the rear part of the base 1 is threaded with the mixing tube 4. The connection between the front of the base 1 and the nozzle 3 is provided with a front sealing ring 6, the connection between the rear of the base 1 and the mixing tube 4 is provided with a rear sealing ring 7, and the opening and cavity at the tail of the nozzle 3 The front part of 2 is connected, and the opening of mixing pipe 4 head is connected with the rear part of cavity 2, and the bottom of base 1 is provided with drainage tube 5, and drainage tube 5 is connected with the bottom of cavity 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com