An experimental device for simulating multi-angle fracture network proppant settlement law

An experimental device and proppant technology, which is applied in the field of experimental devices for simulating the settling law of proppant in multi-angle fracture nets, can solve the problems of inability to adjust the structure, unable to reflect the structure of the fracture network, and not considering wall leakage, so as to achieve real and measured fractures. The effect of reliable data, easy cleaning and replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

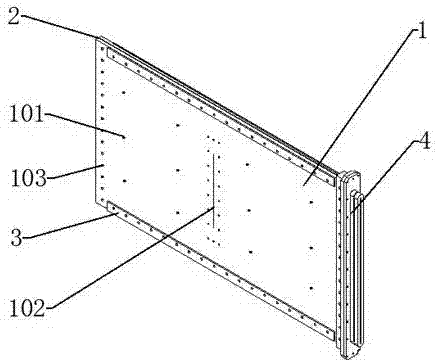

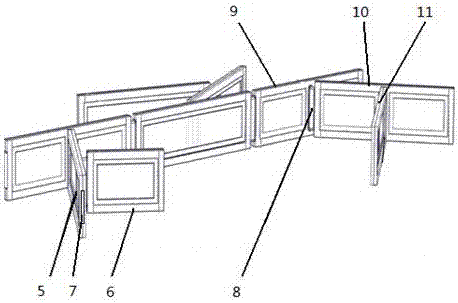

[0039] like figure 1 , figure 2 As shown, an experimental device for simulating multi-angle dynamic fracture network proppant settlement rules includes artificial fractures, and each section of the artificial fractures consists of two parallel transparent organic glass plates 1, and the four sides of the organic glass plates 1 surround bolt holes 103, The upper and lower ends between the plexiglass plates 1 are all provided with sealing strips 2, and the outer sides of the upper and lower ends of the plexiglass plates 1 are all provided with pressure plates 3, and the three are connected and compressed by bolts to form a single closed space; the organic Part of the evenly distributed small holes 101 that can be plugged are set on the glass plate 1, and some of the small holes 101 can be selectively blocked according to the permeability of different formations, so that the loss ratio of the sand-carrying fluid is closer to the real wall leakage. ; The compressive capacity of ...

Embodiment 2

[0042]An experimental device as described in Example 1 is used to simulate the multi-angle dynamic fracture network proppant settlement law experiment, the steps are as follows:

[0043] (1) According to the quantity and viscosity required by the experiment, configure the sand-carrying fluid;

[0044] (2) Prepare the proppant required by the experiment;

[0045] (3) Adjust the branch joints at all levels to the desired test angle and fix them;

[0046] (4) According to the experimental requirements, adjust the opening and closing amount of the small holes on the plexiglass plate;

[0047] (5) Check the cleanliness of the device, if it is dirty, it should be cleaned before use;

[0048] (6) First inject the device with clear water to circulate, check the tightness of the device, and after confirming the seal, empty the device;

[0049] (7) uniformly mixing the sand-carrying liquid and the proppant in the sand mixing tank to form a mixed liquid; pumping the mixed liquid into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com