Device and method for detecting bonding strength of bimetallic plate

A technology that combines strength and detection devices, applied in the direction of measuring devices, using mechanical devices, analyzing materials, etc., can solve the problems of undetectable shear strength values, prone to bending and breaking, and complicated processing of detection samples, and achieve friction Small resistance, accurate and reliable measured data, and high motion precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to facilitate understanding of the present invention, the present invention will be described more fully below in conjunction with specific embodiments.

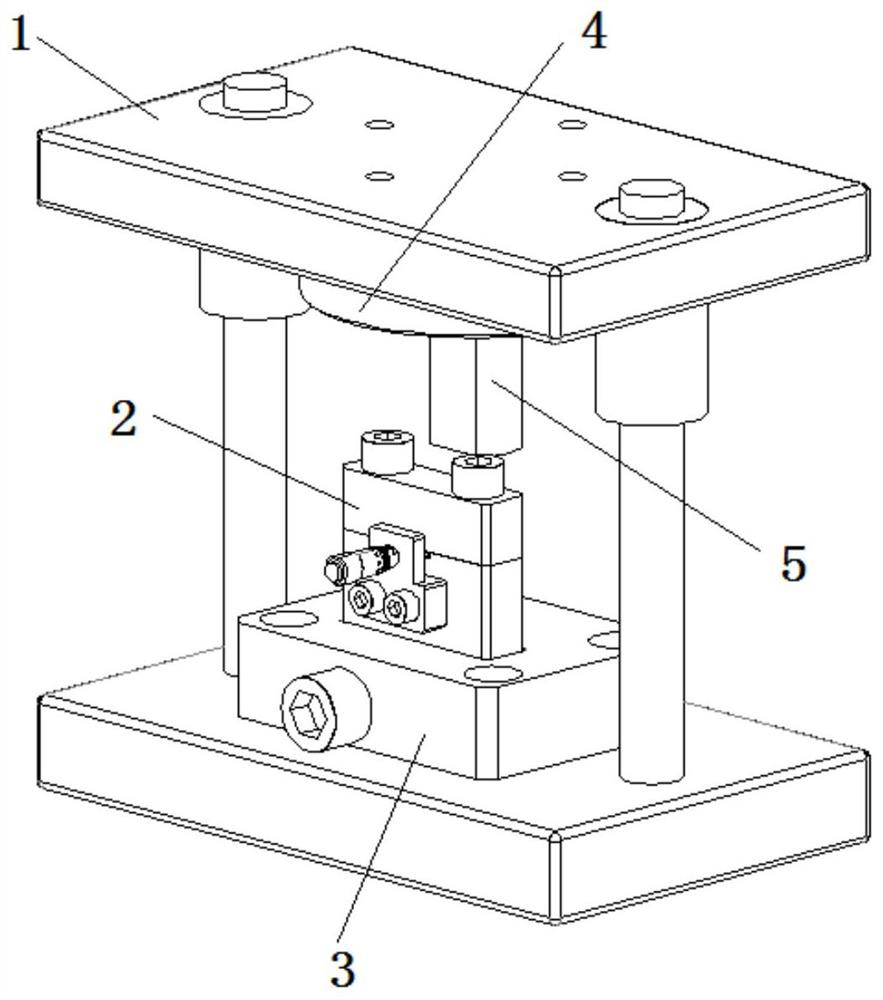

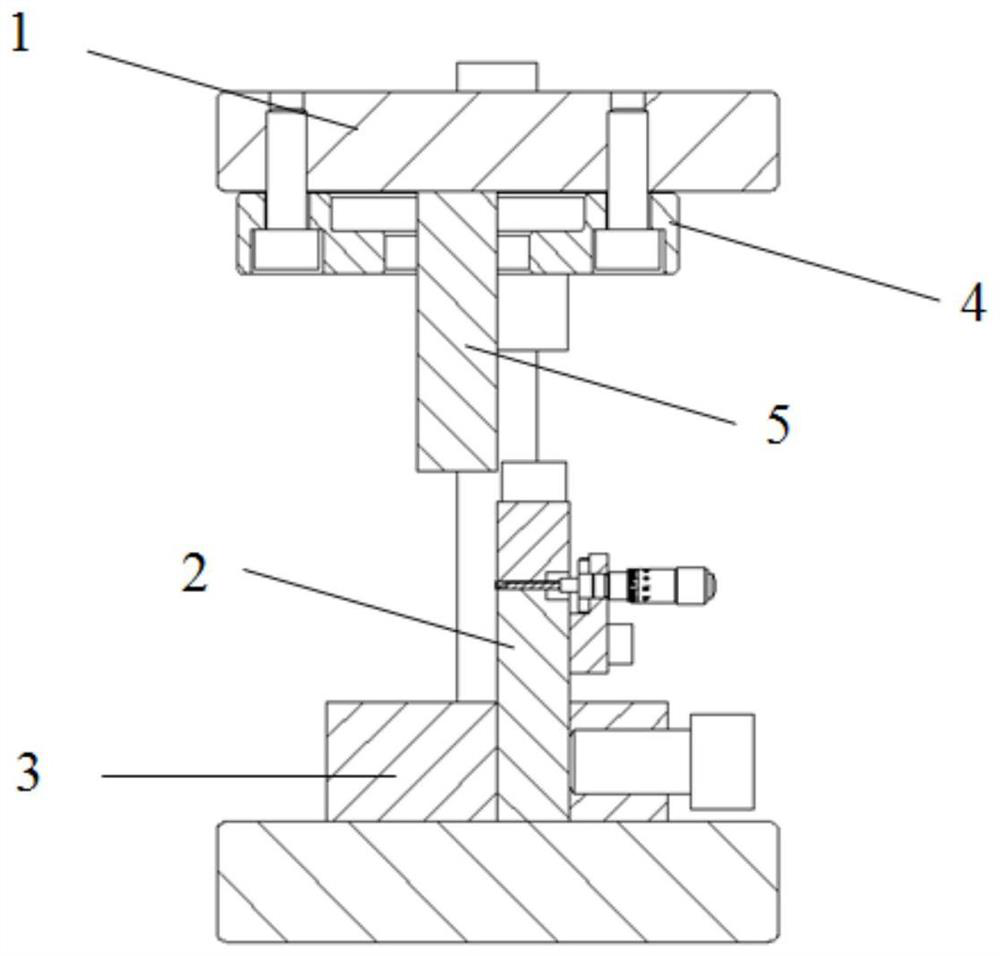

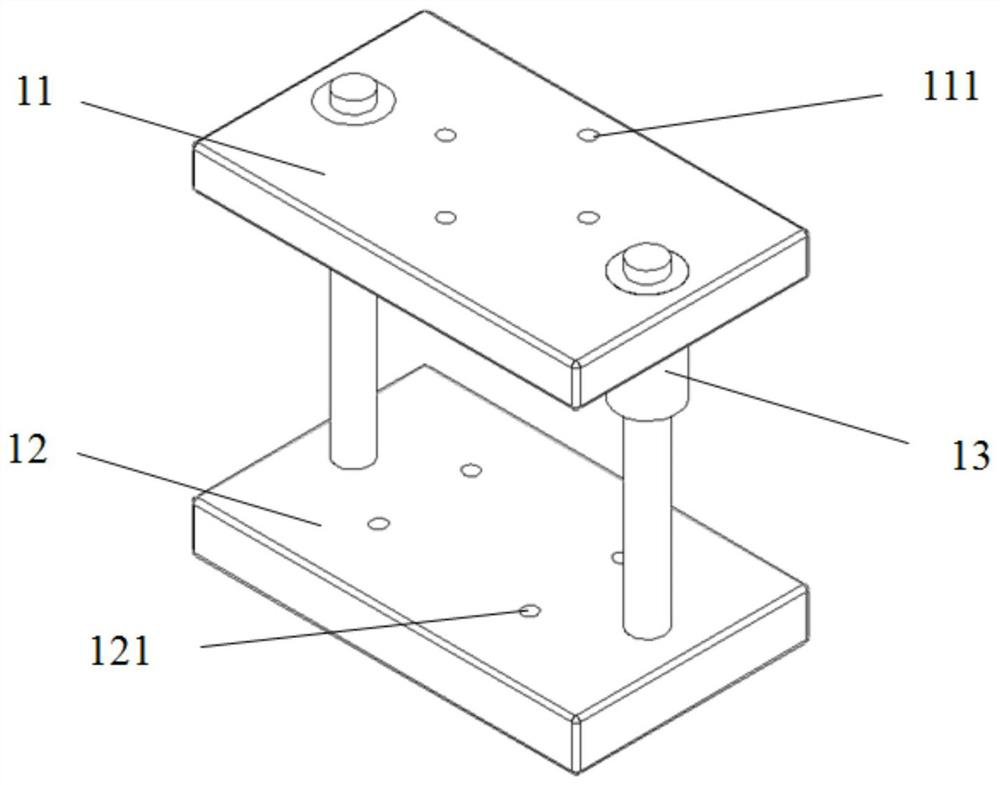

[0062] Such as Figure 1-13 As shown, a detection device for the bonding strength of bimetallic plates includes: an intermediate ball mold set 1, a sample holding assembly 2, and a cutter 5. The intermediate ball mold set 1 includes a horizontally arranged upper template 11 and a The lower formwork 12 just below the upper formwork 11, the upper formwork 11 and the lower formwork 12 are provided with movable joints and the two are movably connected through the active joints, and the upper formwork 11 can move up and down relative to each other in the vertical direction , the upper end surface of the lower template 12 is provided with a positioning and fixing block 3 and the sample holding assembly 2 is installed on the positioning and fixing block 3, the sample holding assembly 2 is used to clamp the sample 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com