A performance testing device and testing method for an electric scooter

An electric scooter and testing device technology, applied in vehicle testing, measuring device, machine/structural component testing, etc., can solve problems such as large testing sites and low data reliability, improve stability, and obtain measured data. Reliable, shortened test time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

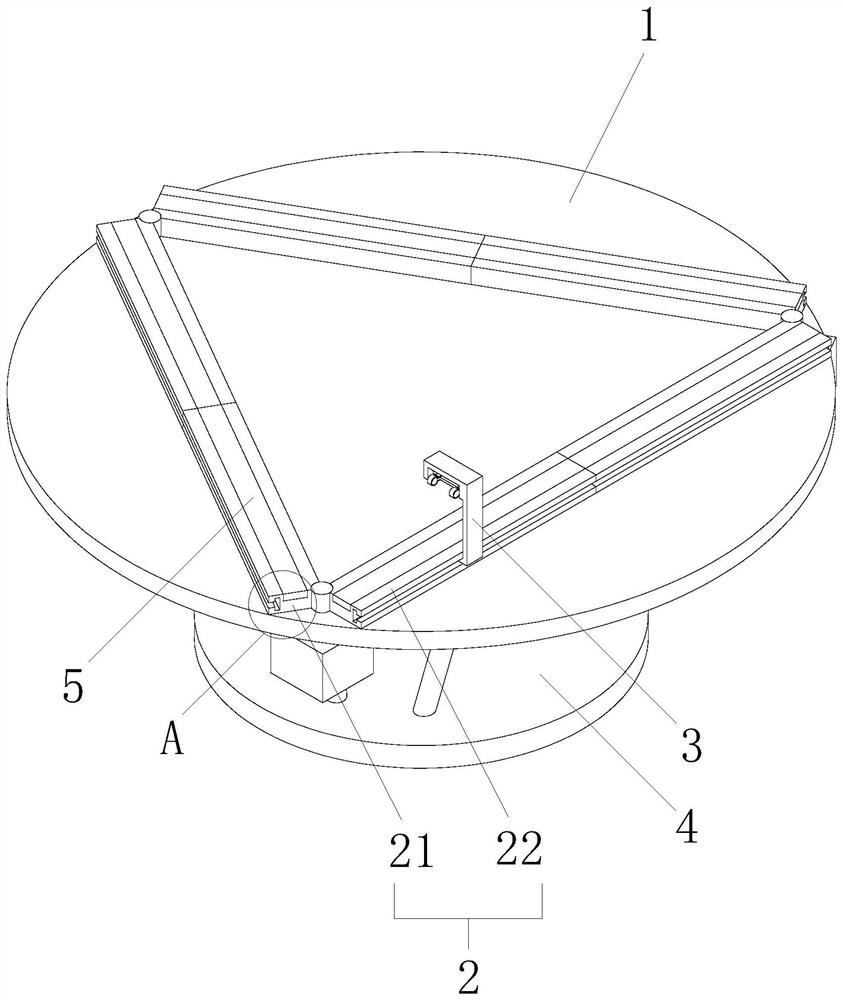

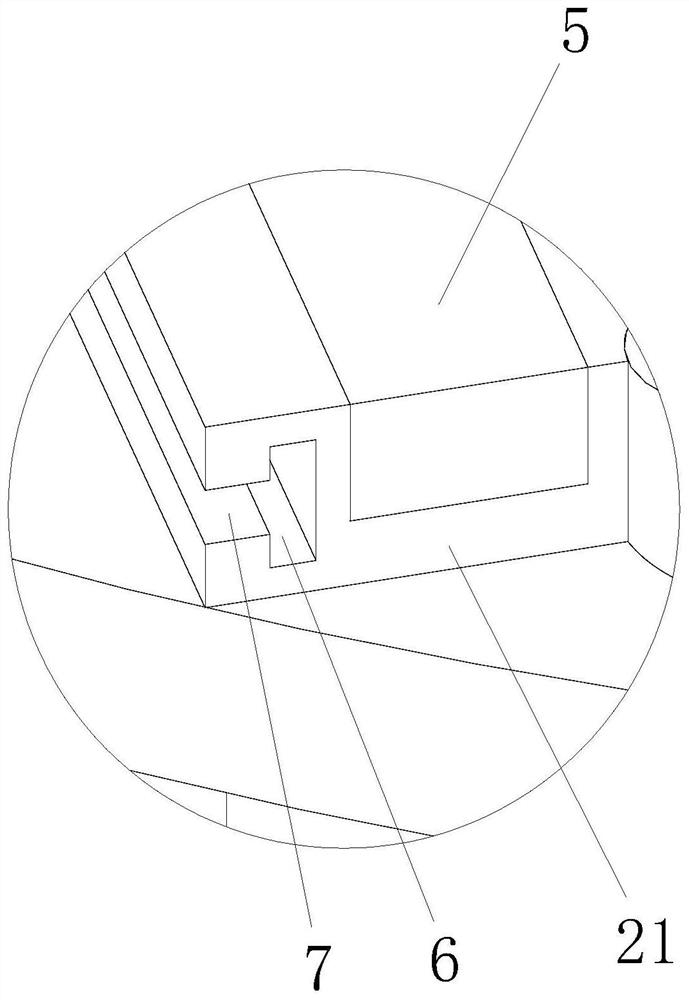

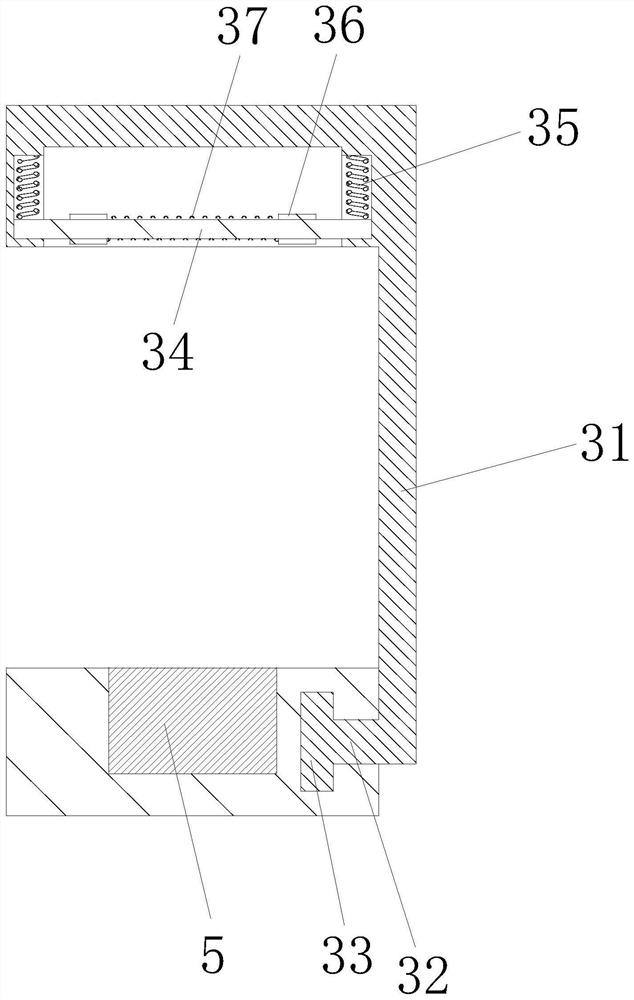

[0031] combined with Figure 1-4 , a performance testing device and testing method for an electric scooter of the present embodiment, comprising a test platform 1 and three test frames 2 arranged on the test platform 1, the three test frames 2 are pre-assembled into a triangular structure, and two adjacent The ends of two test frames 2 abut to form straight sides, and the test frame 2 includes a first test frame 21 and a second test frame 22, and the first test frame 21 is fixedly connected to the test platform 1, and the second test frame 2 is connected to the test platform 1. The test frame 22 is rotatably connected to the test platform 1, the bottom of the test platform 1 is equipped with a motor for driving the rotation of the second test frame 22, and the second test frame 22 is rotatable to abut against the first test frame 21 To form a straight edge, it also includes a handlebar fixing assembly 3 that can move on three test frames 2. The test frame 2 is provided with a ...

Embodiment 2

[0041] A performance testing method of an electric scooter, comprising the following steps: S1, fixing the handlebar of the electric scooter on the handlebar fixing assembly 3, and starting the electric scooter after placing a load on the electric scooter; S2, The electric scooter moves on the test frame 2. When the electric scooter is about to move from the first test frame 21 to the second test frame 22, the second test frame 22 rotates outwards and abuts against the first test frame 21 to form a straight edge. ; S3, the electric scooter moves to the second test frame 22, and the second test frame 22 resets and connects with the first test frame 21 of the adjacent test frame 2 to form a straight edge; S4, the electric scooter moves to the adjacent test frame 2 On the first test frame 21; S5, repeating S1-S4.

[0042] When this method is used to test the performance of the electric scooter, the electric scooter can realize long-distance cycling on three test frames without oc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com