Selective catalytic reduction (SCR) denitration flow field simulation system and method

A technology for simulating systems and flow fields. It is applied in separation methods, chemical instruments and methods, and dispersed particle separation. It can solve problems such as affecting the service life of equipment, affecting denitration efficiency, and increasing equipment pressure loss, so as to achieve true measured data. Reliable, highly informative, compact results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

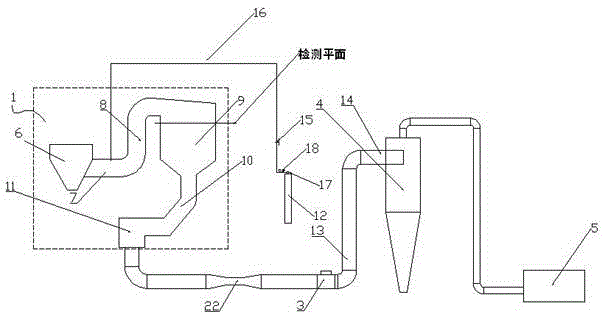

[0024] Such as figure 1 As shown, the SCR denitration flow field simulation system of the present invention includes an SCR denitration reactor model 1, a flow measurement device 2, a dust collector 4, an induced draft fan 5 and a methane gas injection device 12; It is safe, so methane gas is used.

[0025] The SCR denitration reactor model 1 is obtained by reducing the size of the SCR denitration reactor according to the ratio of 1:10 to 1:15 according to the size of the specific project SCR denitration reactor provided by the design manufacturer, including the economizer outlet section 6, The SCR denitrification reactor 9 and the air preheater inlet section 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com