Handheld constant rigidity ring shear apparatus and using method thereof

一种常刚度、手持式的技术,应用在使用施加稳定的剪切力测试材料强度、仪器、测量力等方向,能够解决体积大、设备复杂、环剪仪制造成本和使用成本增加等问题,达到体积小、质量轻便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

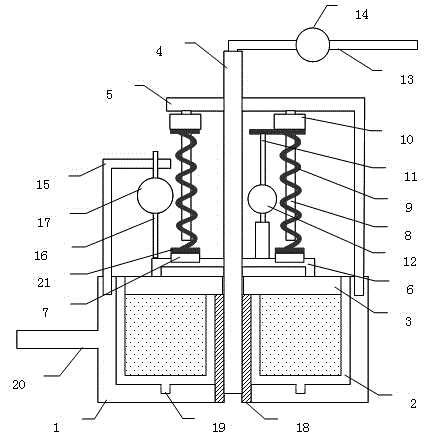

[0034] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

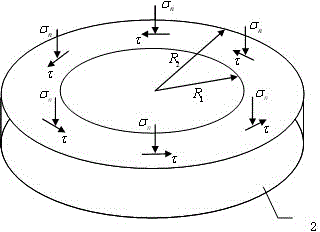

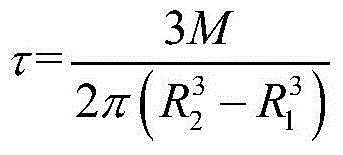

[0035] see figure 1 and figure 2, a hand-held constant stiffness ring shear instrument, comprising a base 1 and an annular steel frame 2 sheathed in the base 1, the top of the steel frame 2 is fastened with an annular upper cover 3, and the upper part of the upper cover 3 is fixed with a transmission Pressing plate 6, a rotating shaft 4 is vertically arranged in the center of the base 1, the rotating shaft 4 passes through the pressure transmitting plate 6 and is fixed with the pressure transmitting plate 6 by threads, a wrench 13 is fixed on the top of the rotating shaft 4, and a wrench 13 is embedded on the wrench 13 Digital display table 14; the side wall of the base 1 is fixed with a spring support 5 by threads, and a spring guide rod 8 is vertically fixed below the spring support 5, and the upper end of the spring guide rod 8 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com