Phase-change temperature-adjusting construction material detector and detection method thereof

A detection device and phase change technology, applied in the investigation phase/state change and other directions, can solve the problems of small number of test samples, small test sample volume, difficult to measure accurately, etc. Diversified Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

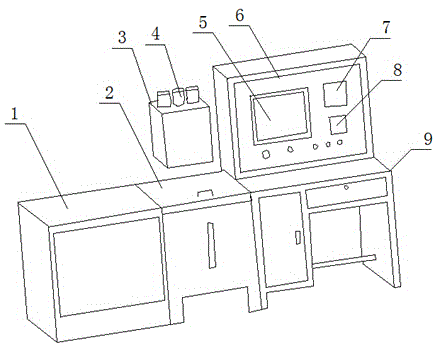

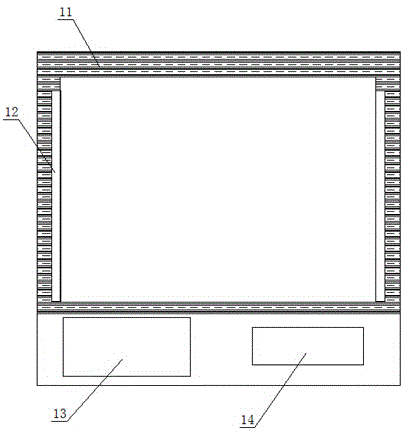

[0031] Such as Figure 1-6 Shown: a phase-change temperature-adjusting building material testing device, including a constant temperature box 1, a test piece box 3, an insulation box 2 and a control cabinet 6, and the constant temperature box 1 includes an outer box, an inner box, a compressor 13, a heater 12 and a temperature The regulator 14 is filled with high-density glass fiber insulation cotton 11 between the outer box and the inner box. The temperature regulator 14 regulates the temperature of the inner box through the compressor 13 and the heater 12 connected to it, keeps its temperature constant, and passes A display on the outer box is provided for temperature display, and the temperature adjustment range of the thermostatic box 1 is 0-65°C.

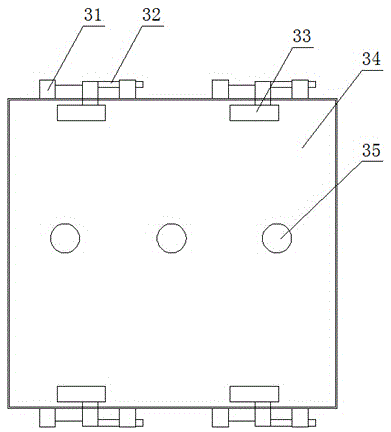

[0032] The test piece box 3 is made of aluminum material, and its specification is 400mm 400mm 400mm, the test piece box 3 includes a box body and a cover plate 34, and its cover plate 34 is connected with the box body thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com