Rotary-scanning online ultrasonic detection method for cylinders

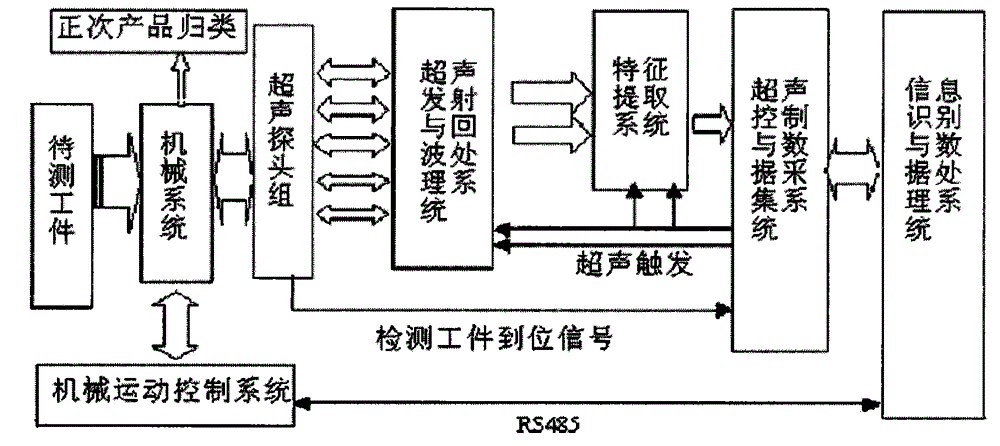

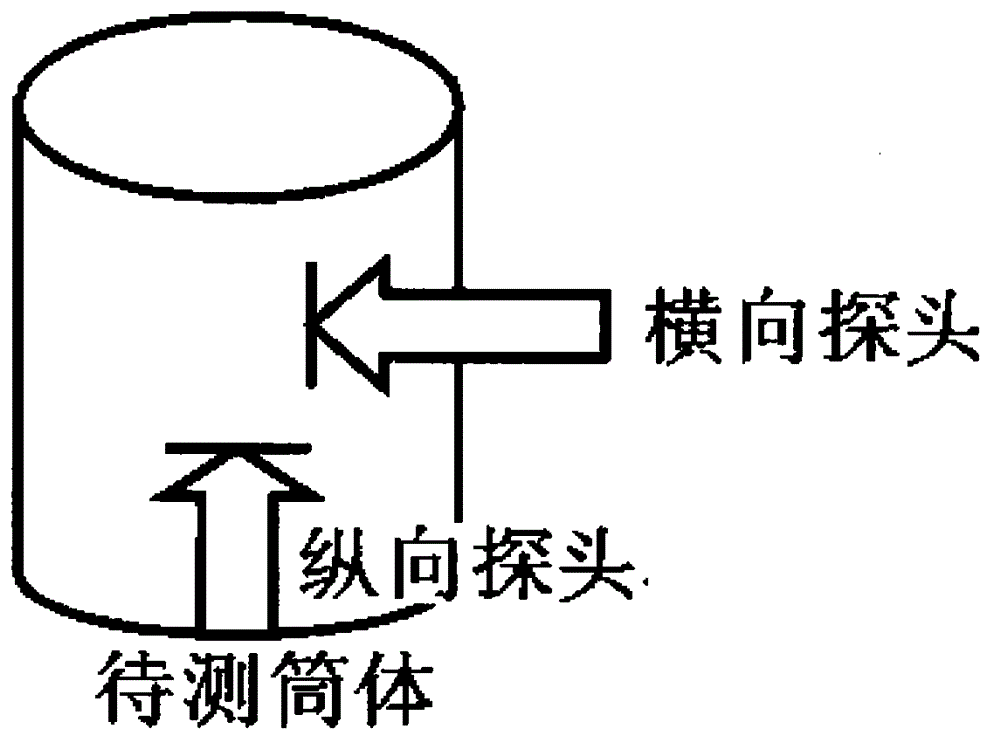

A detection method, a rotary technology, applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., to improve detection efficiency and overcome time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

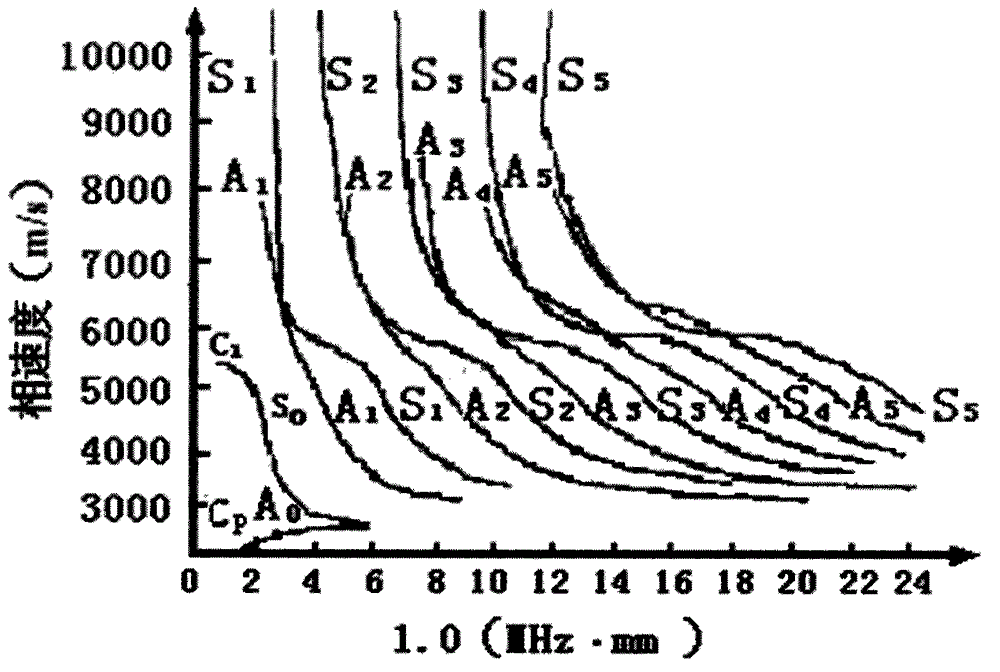

[0027] 1. Mode selection: When using plate waves for detection, in order to facilitate defect identification and detection, it is necessary to ensure that the sound wave propagating in the plate has a single mode and a stable speed as much as possible. For example: when the product of frequency and plate thickness is greater than 4MHz mm, the plate wave group velocity in A0 and S0 modes tends to be a constant, so when a 5MHz probe is used to detect a plate with a plate thickness of about 0.8mm, the plate wave group velocity will not increase significantly. The change. When A0 and S0 plate waves propagate in a uniform thin plate, the waveform will be a regular single-peak pulse, which is beneficial to the waveform identification during detection. From the plate wave equation:

[0028] 4 pq tan ( πfdq Cp ) + ( p ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com