Motor driving system current sensor fault diagnosis method

A technology of motor drive system and current sensor, which is applied in the direction of instruments, measuring electric variables, measuring devices, etc., can solve the problems of cost increase, achieve cost saving, and realize the effect of torque safety control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

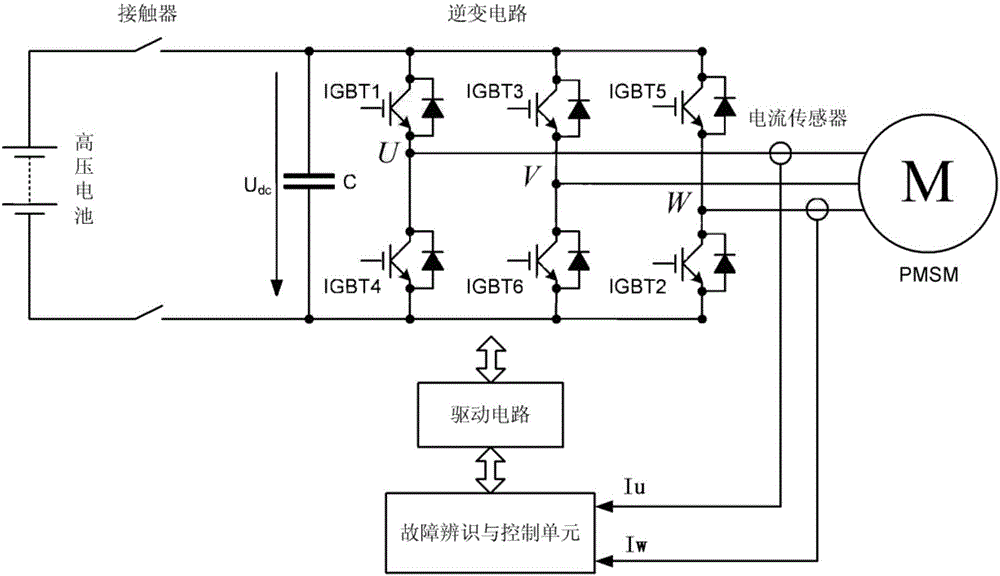

[0020] Motor drive systems such as figure 1 As shown, it includes a motor, a motor controller, a fault identification and control unit, a drive circuit, and two current sensors. The two current sensors detect the current of any two phases of U, V, and W of the three-phase motor. The fault identification and The control unit performs fault diagnosis on the current sensor itself based on the current detection values of the two current sensors.

[0021] Motor drive system current sensor fault diagnosis method:

[0022] Use the first current sensor and the second current sensor to detect the current of any two phases of the three-phase motor respectively;

[0023] Sampling the phase current detected by the first current sensor and the phase current detected by the second current sensor, the number of sampling points in one phase current cycle is N;

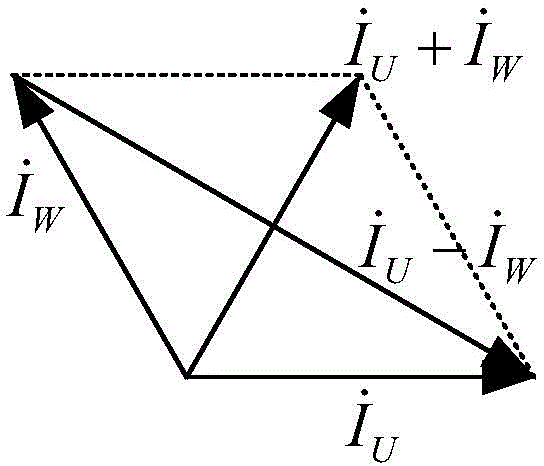

[0024] Calculate the N phase current amplitudes in a phase current cycle, In the formula, A(M) is the Mth phase current amplit...

Embodiment 2

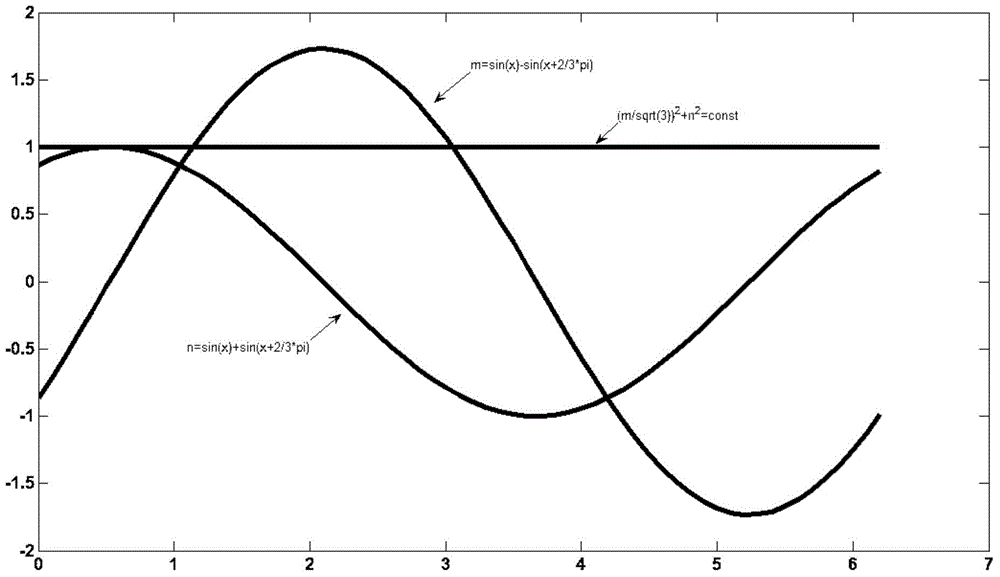

[0031] Based on the motor drive system current sensor fault diagnosis method in Embodiment 1, a phase current starting from the peak time (the peak time can be selected as the positive peak value or the negative peak value) of the phase current detected by the current sensor is also calculated. Each accumulated current value within the current cycle and calculate the sine degree, If the N sine degrees in the phase current cycle are not constant (that is, more than P sine degrees exceed the sine degree threshold range, P is a positive integer less than N, and the sine degree threshold range is obtained by matching), then judge the phase The current is non-sinusoidal, and the current sensor has a serious or precision failure; I' M is the cumulative current value up to the Mth sampling point in the phase current cycle, I M is the Mth sampling value in the phase current cycle, I k is the kth sampling value in this phase current cycle, I 1 is the current sampling value at the p...

Embodiment 3

[0049] Based on the motor drive system current sensor fault diagnosis method of Embodiment 2, within a phase current cycle, if the sampled value of the phase current detected by a current sensor is always a constant value, such as: ±Imax, or between ±Imax A certain constant value of , it is judged that the current sensor is unreasonable, and the current sensor has a serious fault.

[0050] It should be noted that in special working conditions, such as locked rotor or large-scale fluctuation of torque command, the accuracy fault diagnosis of the current sensor can be disabled first (that is, the balance and sine degree diagnosis should be disabled), and only for serious faults of a single current sensor Carry out diagnosis (that is, only open the rationality diagnosis of the single-phase current in Embodiment 3, and the locked-rotor working condition can be known from the motor position sensor), so as to avoid false alarms of diagnostic faults. Due to the limited duration of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com