Preparation method for large-format electropositive organic photoconductive drum and organic photoconductive drum prepared with method

An organic photoconductive drum and large-format technology, which is applied to the equipment of the electric recording process applying the charge pattern, the electric recording process applying the electric charge pattern, optics, etc. The thickness and uniformity are not easy to guarantee, and the processing design of dipping equipment is difficult to achieve the effect of easy preparation and purification process, simple structure and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the large-format positively charged organic photoconductive drum of the present invention adopts a low-pressure atomization film-forming method, comprising the following steps:

[0018] ① Spray the pre-coating paint on the base of the large-format organic photoconductive drum. The preparation method of the pre-coating paint is: dissolve the vinyl acetate resin and solvent at a mass ratio of 1:50-100;

[0019] ② After the pre-coating layer is fully dried, spray photosensitive paint. The preparation process of photosensitive paint is: Y-type phthalocyanine titanium oxide and solvent are uniformly dispersed by ball milling according to the mass ratio of 1:30-40, and then prepared into a generating material solution; 3 ,3′-Dimethyl-5,5′-di-tert-butyldiphenoquinone, styryltriphenylamine, polycarbonate resin, and solvent are dissolved in a mass ratio of 1:2-3:4-5:120-180 Prepare a transmission material solution; mix the generating material solution a...

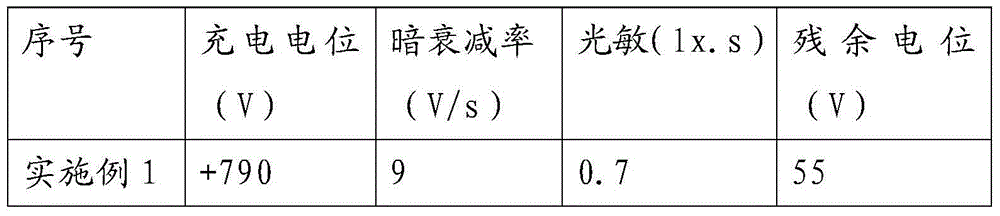

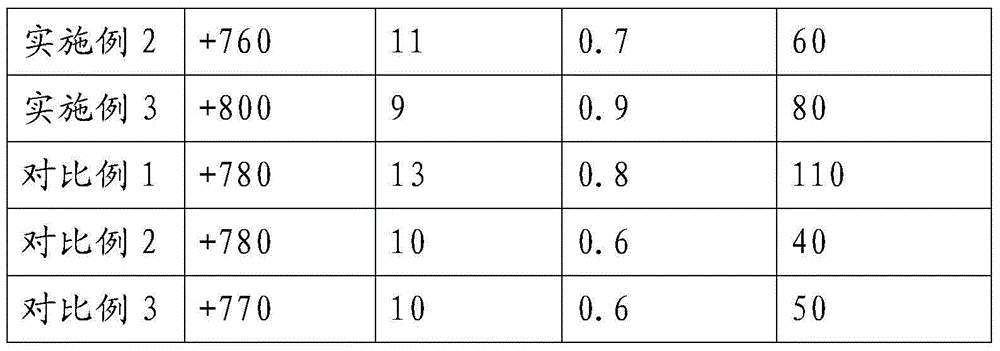

Embodiment 1

[0022] Example 1: ① Preparation and spraying of pre-coating paint: Dissolve 10 g of vinyl acetate resin SB-A in 800 ml of methyl ethyl ketone solvent to make a pre-coating solution, and spray it on the drum base to form a pre-coating. The organic photoconductor drum was baked in a drying oven at 100° C. for 10 minutes. ② Preparation of the generating material solution: Mix 1 g of Y-type titanium phthalocyanine and 40 ml of cyclohexanone, ball mill for 24 hours to disperse evenly, and prepare the generating material liquid for later use. ③Preparation of transmission material solution: 10g of 3,3′-dimethyl-5,5′-di-tert-butyldiphenoquinone, 20g of styryl triphenylamine, 40g of polycarbonate resin and 1800ml of toluene were fully dissolved and mixed for preparation ④ Preparation of photosensitive coating solution: mix 20ml of generating material solution and 500ml of photosensitive coating solution, ball mill for 12 hours and disperse evenly to prepare photosensitive coating solut...

Embodiment 2

[0024] Embodiment 2: Except that styryl triphenylamine is changed from 20 g to 30 g in the preparation of the transmission material solution in step ③, everything else is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com