Electric tool

A technology of electric tools and power supplies, which is applied in the direction of electrical components, emergency protection circuit devices, etc., and can solve the problems of bolts that are easy to fall, fall, and easy to lose, and achieve the effect of avoiding falling and preventing loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

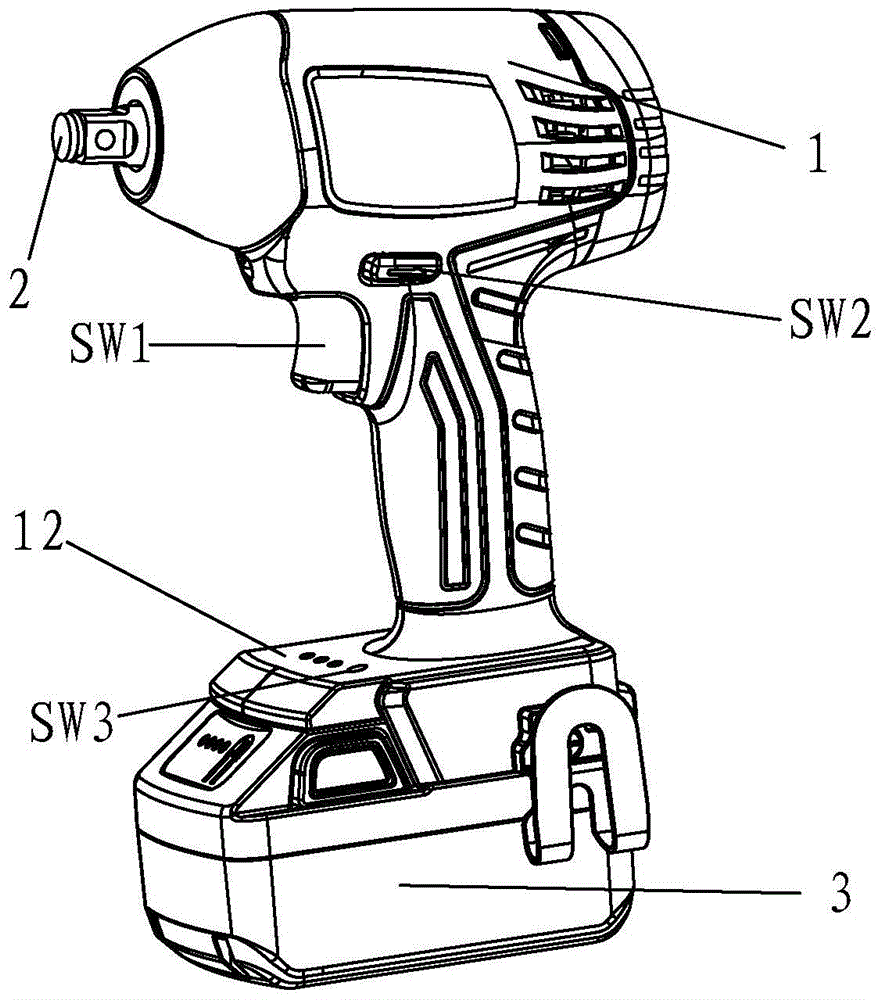

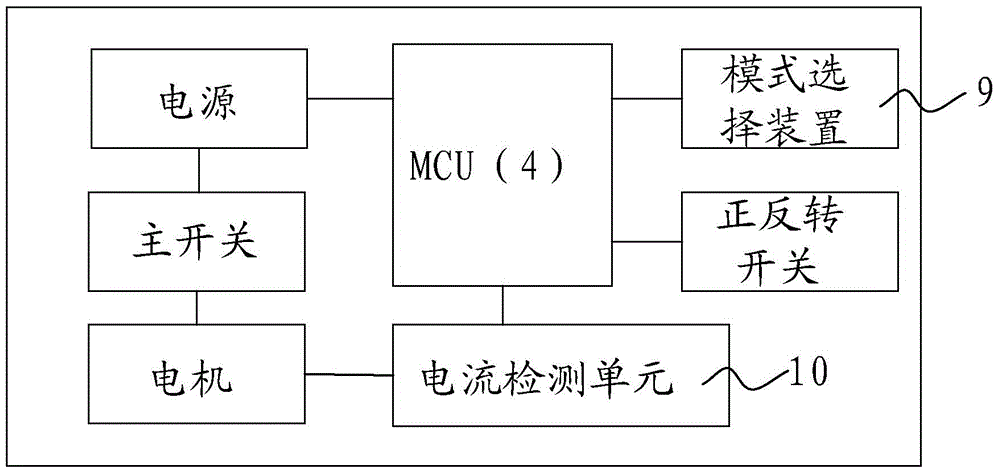

[0026] Reference attached figure 1 and attached image 3 As shown in the electric tool, the electric tool mainly includes a housing 1, a motor (not shown in the figure) located in the housing, a working head 2 driven by the motor, a battery pack 3 connected to the tool body as a power source, and a control motor The start / stop main switch SW1 and a controller MCU4, the controller MCU4 can receive the signals of the main switch SW1, the forward and reverse switch SW2, the mode selection switch SW3 and the current detection unit 10, and accordingly control the motor to perform corresponding actions.

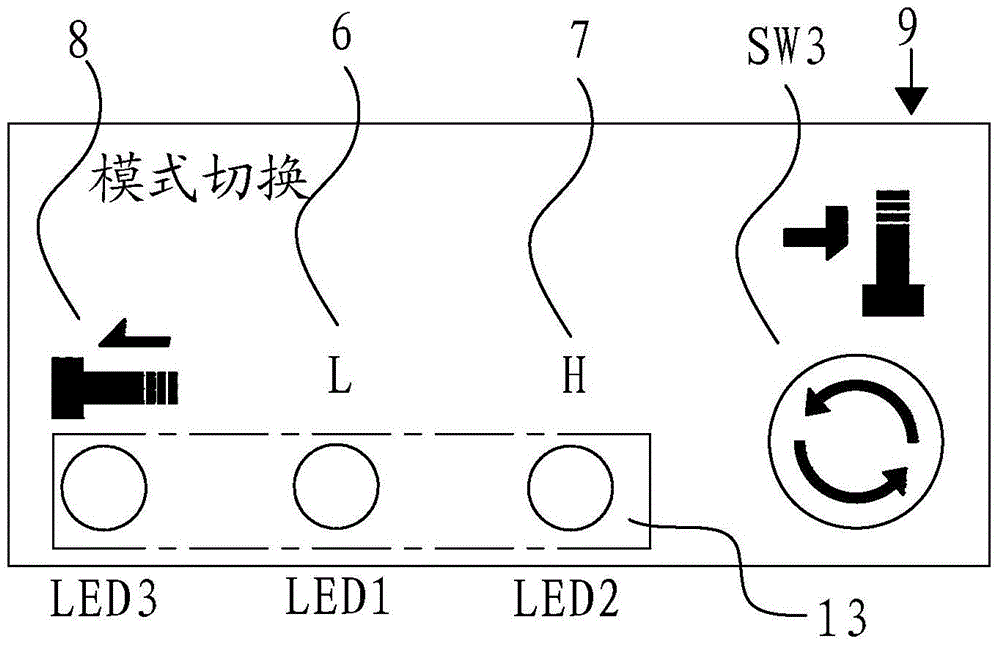

[0027] Reference attached image 3 And attached Figure 4 As shown, the power tool has three working gears, low torque gear 6, high torque gear 7 and fastener withdrawal gear 8. The operator can switch among the three working gears by pressing the mode selection switch SW3 of the mode selecting device 9, and the operator can know the selected working gear through the LED light o...

Embodiment 2

[0032] Refer to attached Figure 7 And attached Figure 8 As shown, compared with Embodiment 1, in Embodiment 2, the electric tool does not have a mode selection device and a display device, and the others are basically the same as Embodiment 1. The operator triggers the main switch SW1 to turn on the motor power, the controller MCU14 receives the signals of the main switch SW1 and the forward and reverse switch SW2, if the forward and reverse switch SW2 is in the forward position, the controller MCU14 adjusts the duty of the output current To adjust the output torque and speed of the brushless motor, if the forward and reverse switch SW2 is in the reverse position, the controller MCU14 receives the sampled current value from the current detection unit 20, and compares the current value with the pre-stored value in the controller MCU14 Compared with the preset current value, if the motor current value is continuously lower than the preset current value within a predetermined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com