EMC circuit

A circuit and filter circuit technology, which is applied in the field of electronic ballasts, can solve the problems of not being able to meet the requirements of the high frequency band, not being able to meet the middle frequency band, and the filtering effect of the primary common mode filter circuit is not good enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

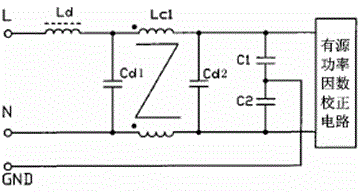

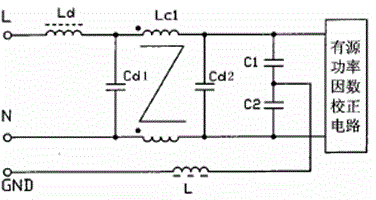

[0014] Embodiment 1, appended image 3 It is a circuit diagram of an EMC circuit, including a differential mode filter circuit and a common mode filter circuit connected in sequence, the common mode filter circuit is electrically connected to an active power factor correction circuit, and the differential mode filter circuit includes a differential mode inductance Ld, a differential mode capacitor Cdl and a differential mode Mode capacitor Cd2, common mode filter circuit includes common mode inductor LCl, common mode capacitor Cl and common mode capacitor C2, differential mode inductor Ld and differential mode capacitor Cdl are connected in series at both ends of the power supply, common mode inductor LCl and differential mode capacitor Cd2 and The differential mode capacitor Cd1 is connected in parallel, the common mode capacitor Cl and the common mode capacitor C2 are connected in parallel with the differential mode capacitor Cd2 after being connected in series, and the joint...

Embodiment 2

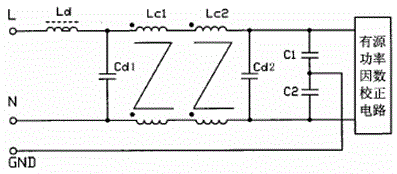

[0028] Embodiment 2, with Figure 4 It is a circuit diagram of an EMC circuit, including a differential mode filter circuit and a common mode filter circuit connected in sequence, the common mode filter circuit is electrically connected to an active power factor correction circuit, and the differential mode filter circuit includes a differential mode inductance Ld, a differential mode capacitor Cdl and a differential mode Mode capacitor Cd2, the common mode filter circuit includes common mode inductor LCl, common mode inductor LC2, common mode capacitor Cl and common mode capacitor C2, differential mode inductor Ld and differential mode capacitor Cdl are connected in series at both ends of the power supply, differential mode capacitor Cd2 and The differential mode capacitor Cdl is connected in parallel, the common mode inductor LCl and the common mode inductor LC2 are connected in parallel with the differential mode capacitor Cdl, the common mode capacitor Cl and the common mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com