Optical sensor unit

A technology of optical sensors and unit shells, which is applied in the direction of instruments, electrical components, scientific instruments, etc., can solve the problems of light leakage detection accuracy, manufacturing energy consumption, and reduction, so as to achieve yield rate, increase manufacturing efficiency, and prevent printed wiring The effect of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

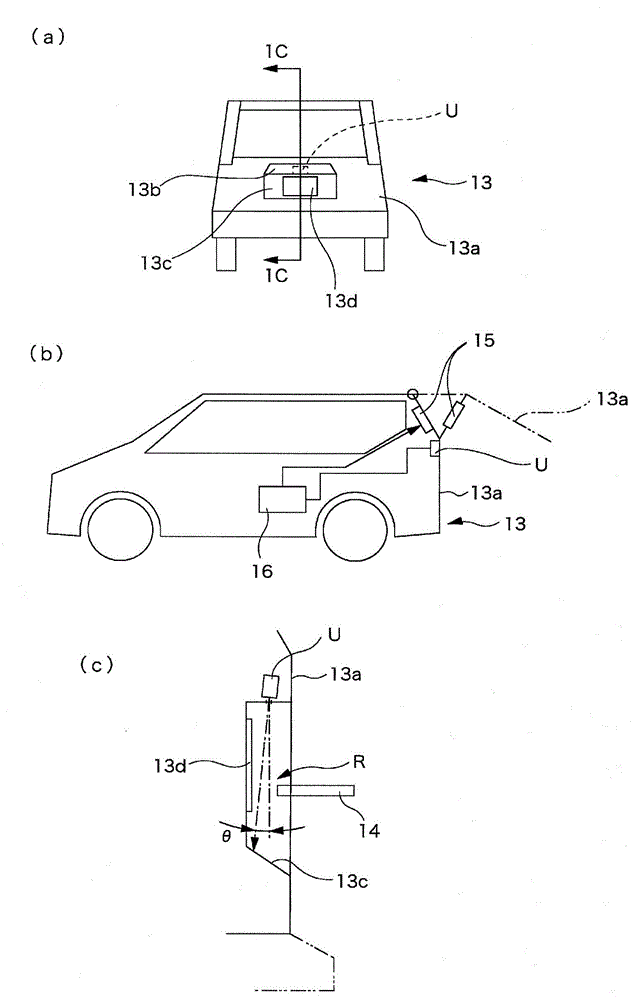

[0031] figure 1 A vehicle 13 to which the present invention is applied is shown. In this example, the photosensor unit (U) is used while being fixed to the rear door 13a in order to control the opening and closing operation of the rear door 13a of the vehicle.

[0032] As will be described later, the optical sensor unit (U) is configured to output a detection signal when detecting that the detection object 14 enters a predetermined detection area (R) onto which detection light is projected, and the optical sensor unit (U) is fixed to the The top wall portion of the license plate mounting recess 13c surrounded by the license plate decoration 13b. It should be noted that, in figure 1 In , reference numeral 13d denotes a car license plate.

[0033] Also, in this example, the optical axis of the detection light is slightly inclined toward the vehicle inner side (angle θ) so that the center of the detection area (R) of the photosensor unit (U) is located in the license plate mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com