A new type of greenhouse insulation quilt

A technology for thermal insulation quilts and greenhouses, applied in greenhouse cultivation, climate change adaptation, gardening, etc., can solve the problems of short service life, deviation, labor and money, etc., and achieve long service life, light weight and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

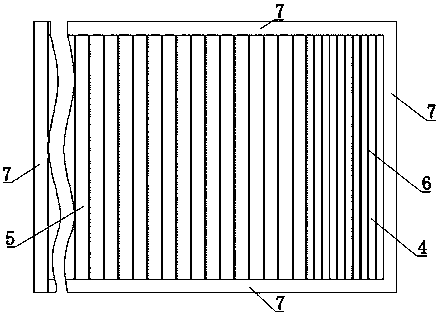

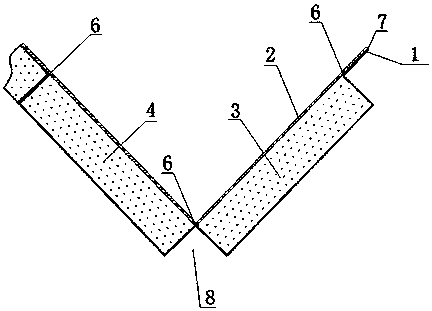

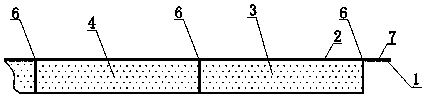

[0018] Figure 1-4 For the same example, such as Figure 1-4 As shown, a new greenhouse insulation quilt includes the first layer 1, the second layer 2 and the interlayer 3 between the first layer 1 and the second layer 2. The interlayer 3 is composed of two foam boards of different sizes arranged in parallel. , the foam boards include foam boards A4 and foam boards B5, the number of foam boards A4 is 10, and they are sequentially arranged at one end of the insulation quilt, the foam boards B5 are arranged in sequence along the foam boards A4, and the outer layer of the foam boards is provided with the first layer 1 and The second layer 2, the first layer 1 is non-woven fabric, the second layer 2 is polyester cloth, the non-woven fabric is in contact with three faces of the foam board, the polyester cloth is in contact with one face of the foam board, and two adjacent foam boards There is a seam spacing of 6 between the boards, and the non-woven fabric and polyester cloth are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com