Horizontal slurry material stirring uniform distribution filling machine

A pouring machine, horizontal technology, applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of material waste, equipment surface aging, uneven distribution of slurry, etc., to ensure the quality of uniform distribution , Position positioning is simple, the effect of reliable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

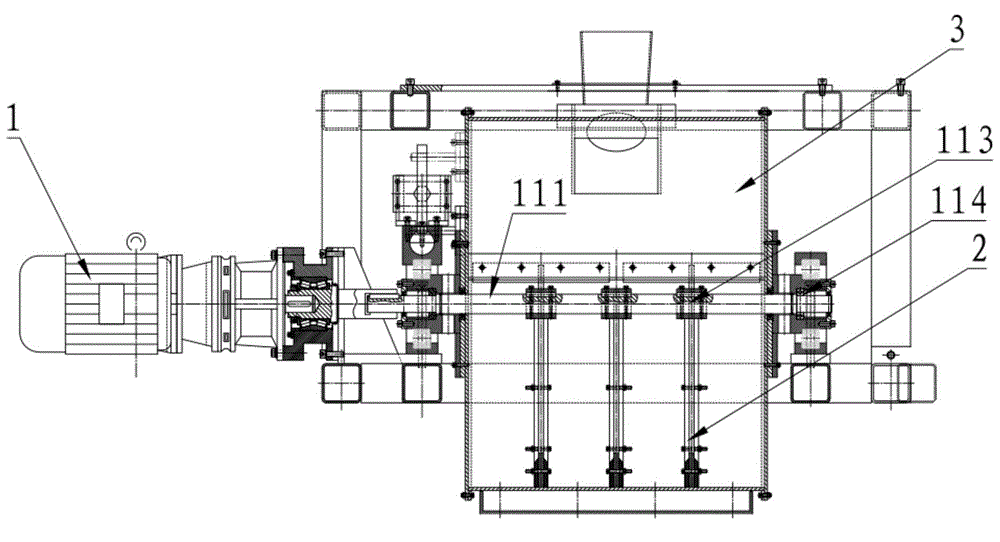

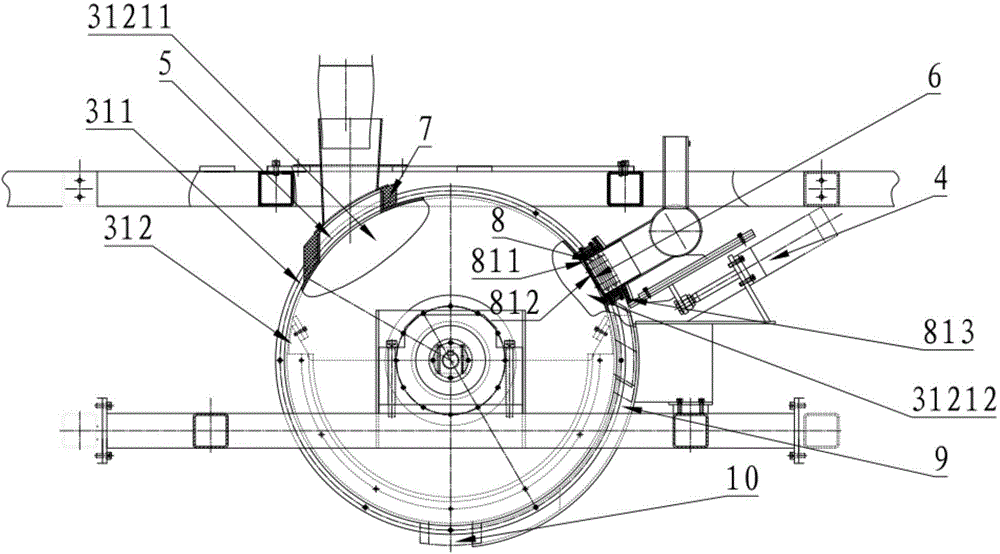

[0026] As shown in the figure, the horizontal slurry stirring and evenly distributing pouring machine of this embodiment includes a stirring motor 1, a stirring and evenly distributing paddle 2, a stirring chamber 3, and a water outlet plug moving cylinder 4 arranged outside the stirring chamber for adding water. The outer bin 311 of the stirring bin is fixed, the inner bin 312 can rotate, and the position of the inner bin 312 for adding materials and water is the initial position. After the material is rotated, it must return to the initial position for the next mixing. The moving cylinder 4 can realize the water injection function of the water tank to the mixing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com