Method for controlling finish rolling steel throwing speed of hot continuous rolling mill

A technology of throwing steel speed and hot continuous rolling mill, which is applied in the direction of roll speed control, etc., and can solve the problems of affecting the quality of the strip tail and coiling stability, unstable operation, and prone to coiling edge damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

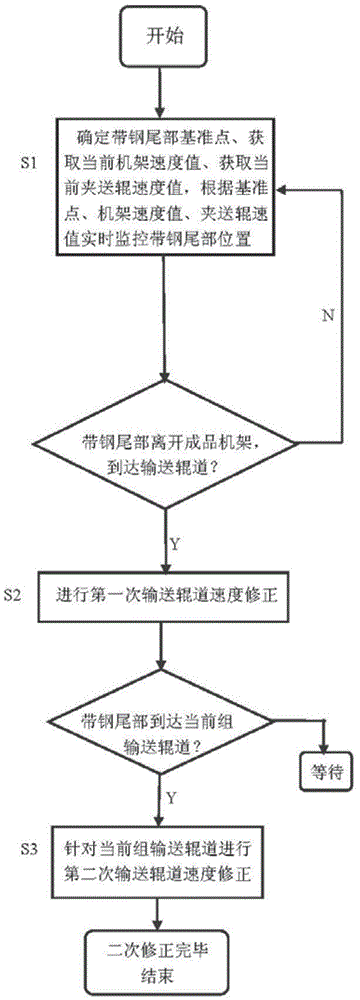

[0037] In the following, a method for controlling the finishing rolling and throwing speed of a hot continuous rolling mill according to the present invention will be further described in detail according to the accompanying drawings and specific embodiments.

[0038] As shown in the figure, a method for controlling the speed of finishing rolling and throwing steel in a hot continuous rolling mill, the specific control technical scheme is as follows:

[0039] 1. Judging the position of the strip steel after throwing

[0040] Combined with the tail position tracking of the strip, the change of the rolling force of the stand is used as a condition in this technical solution to determine the specific position of the tail of the strip. The specific scheme is:

[0041] 1.1. Taking the rolling force signal of the rack as the judgment condition, judge the specific position of the tail of the strip, and use it as the reference point of the tail of the strip;

[0042] 1.2. After knowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com