Press ejector

A technology of demolding device and press, applied in the direction of press, peeling device, metal processing equipment, etc., can solve problems such as major safety hazards, and achieve the effect of avoiding safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

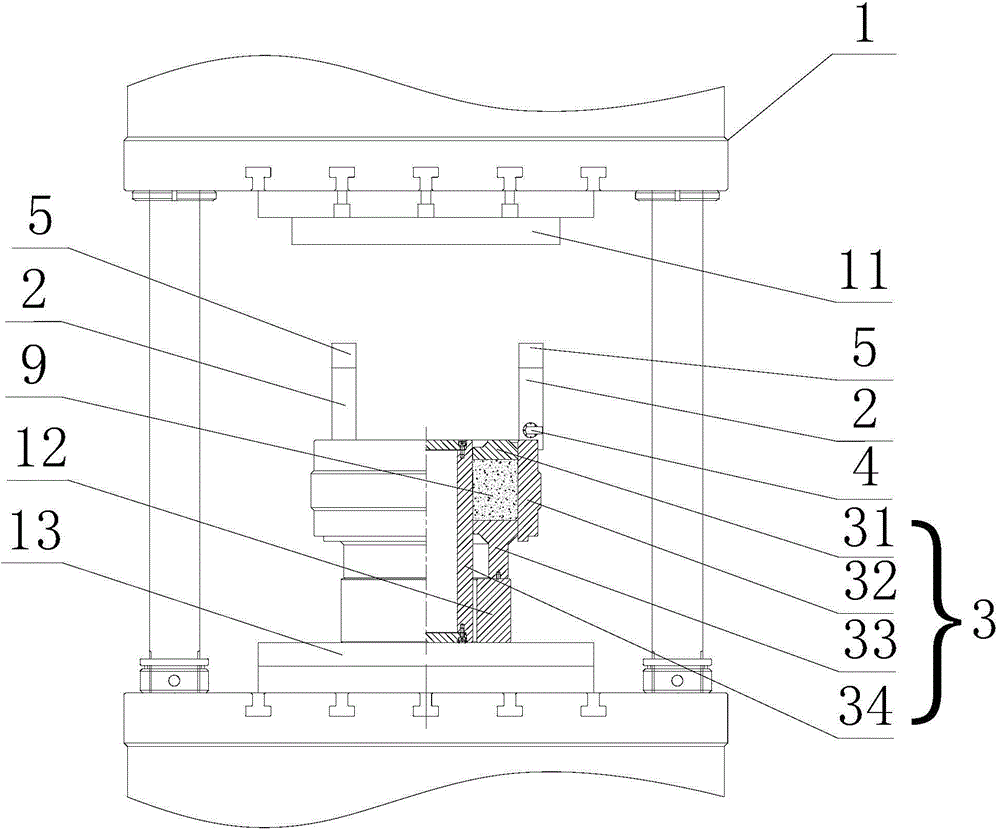

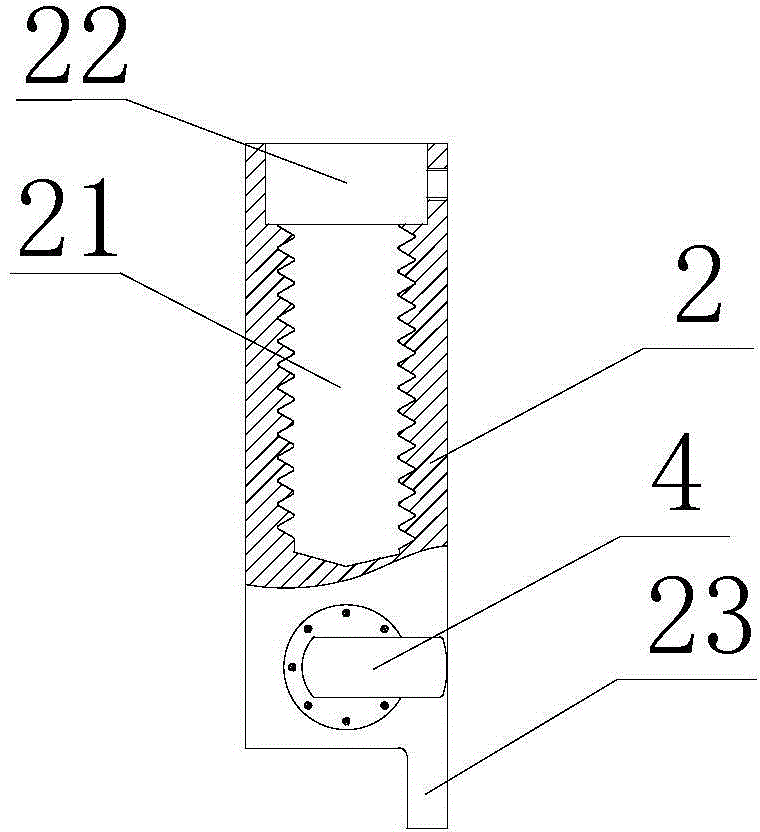

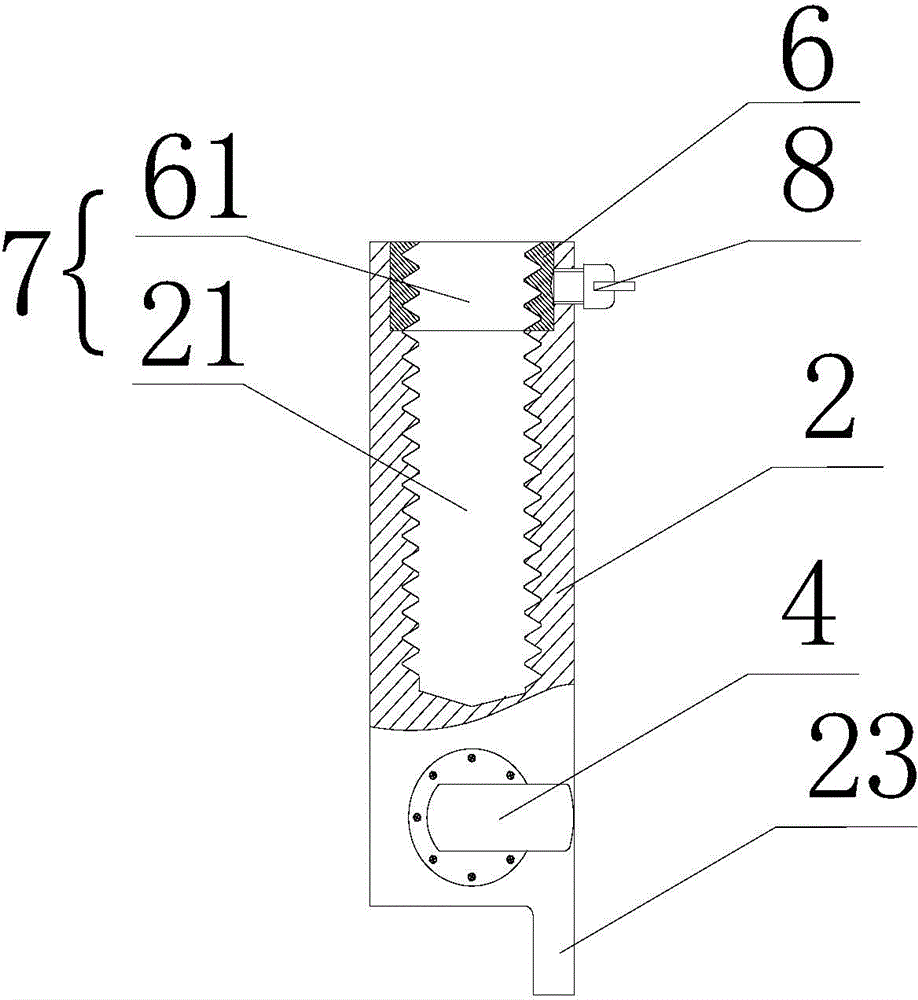

[0018] refer to figure 1 , a press demoulding device, including a press head 11 located at the top of the press 1, a workbench located at the bottom of the press 1 and used to support the combination of the workpiece 9 and the mold 3, and at least two for demoulding Ejector 2, each of the ejector rods 2 is installed on the upper end of the mold 3 through the magnetic base 4 arranged at its lower part; the mold 3 includes an outer cylinder 32, an inner cylinder 34 installed on the workbench, located The upper formwork 31 at the upper end between the cylinder 32 and the inner cylinder 34, the lower formwork 33 located at the lower end between the outer cylinder 32 and the inner cylinder 34 and installed on the workbench, the ejector rod 2 is evenly installed on the upper end of the outer cylinder 32, the top The diameter of the rod 2 is smaller than the wall thickness of the outer cylinder 32; the workbench includes a base plate 13 fixedly connected to the lower part of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com