Method for solidifying much waster liquid based on alkali slag cement

A technology of alkali slag cement and high-level waste liquid, applied in the field of building materials, alkali slag application and treatment of radioactive waste, can solve the problems of large proportion of radioactivity, poor anti-leaching performance, etc., to protect the environment, reduce pollution, and be conducive to sustainable development effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

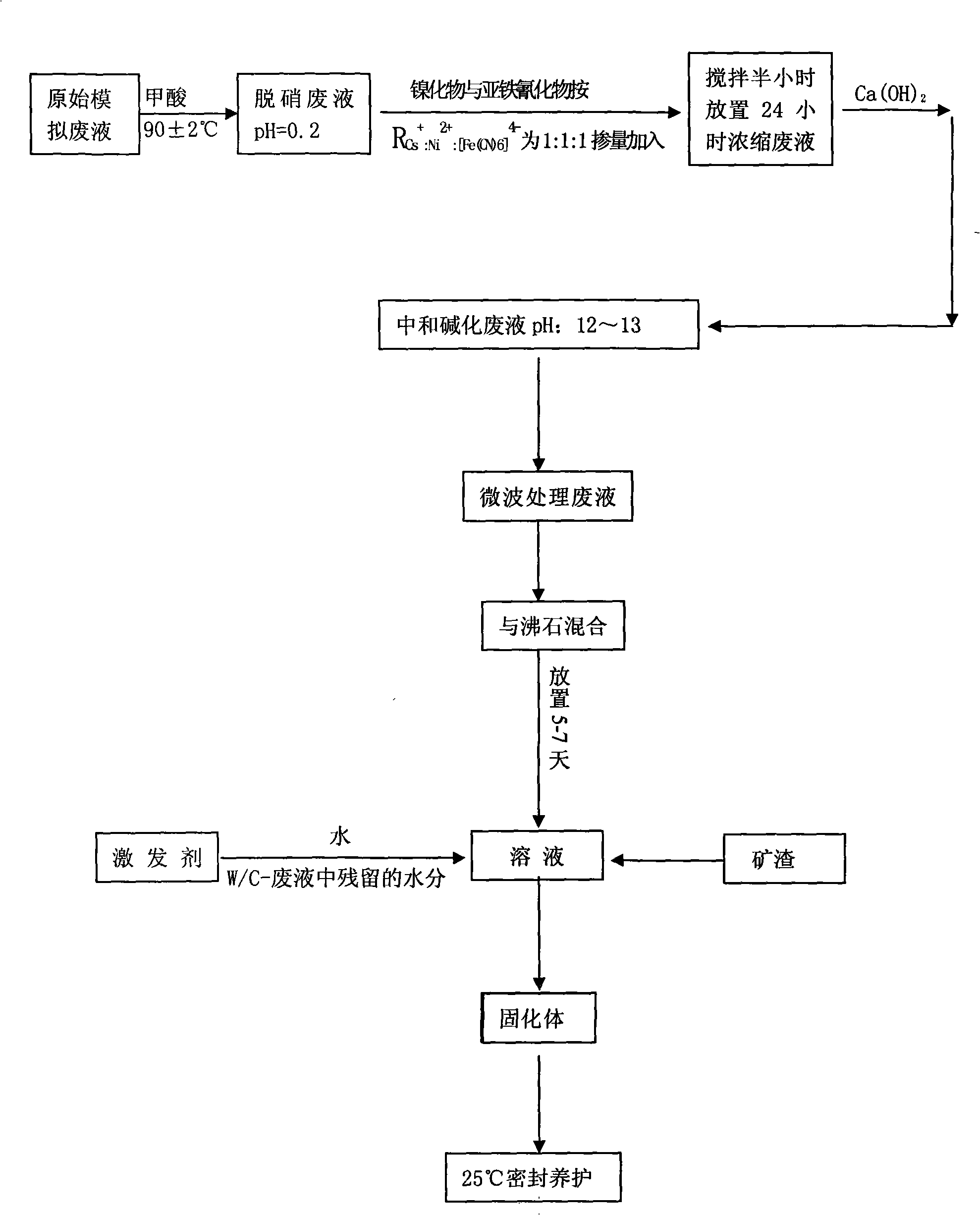

[0018] craft see figure 1

[0019] The effective volume of the reaction vessel is 1 liter

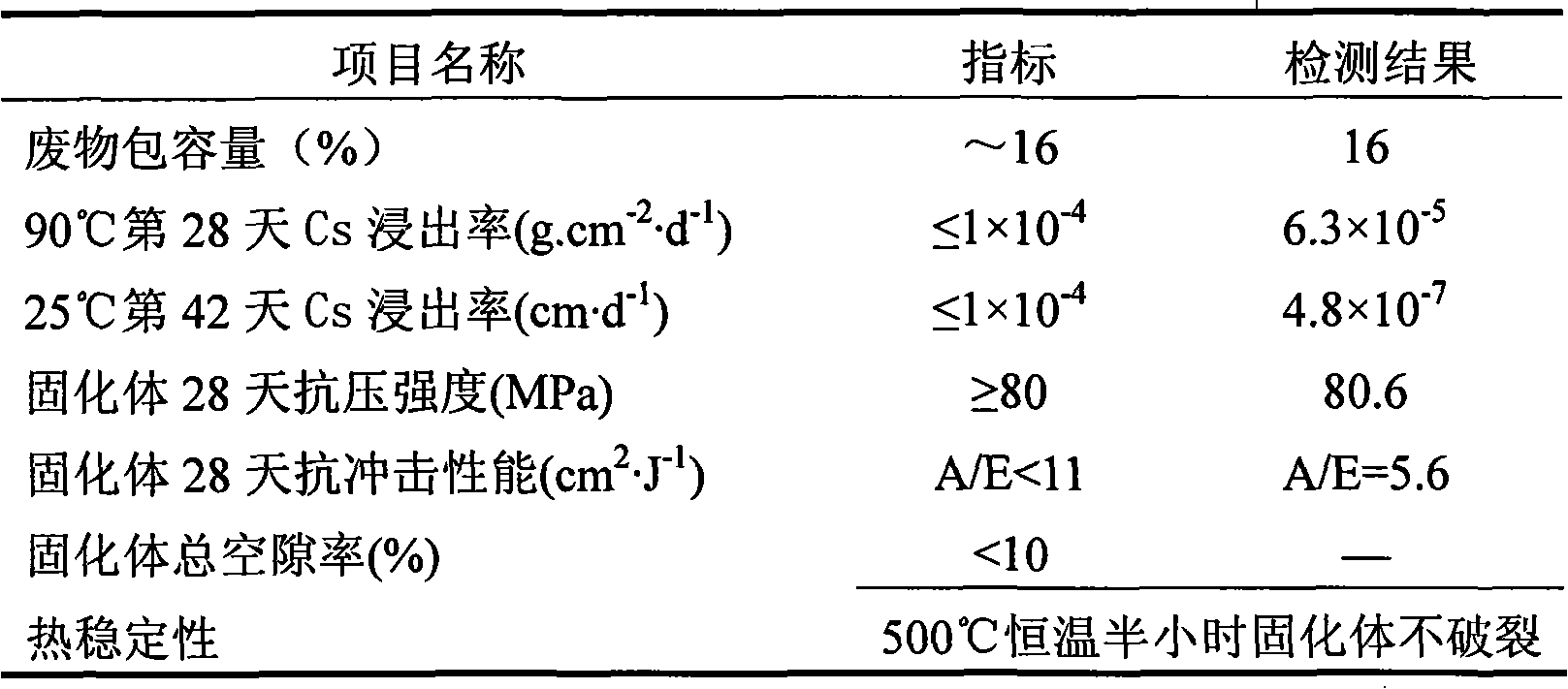

[0020] The simulated high-level waste liquid is based on the composition of typical high-level waste liquid in my country (320 grams of salt, 2molHNO acidity 3 / L) prepared. Measure 0.5 liters of simulated feed liquid into the reaction container, add 0.12 g of nickel compound and 0.29 g of ferrocyanide and stir for 30 minutes. After standing for 24 hours, heat with 0.5-2.1 kilowatt microwave at 99 ° C for 20 minutes, add Ca ( Oh) 2 60 grams of the neutralized pH value is 12, and then heated by 0.5-2.1 kilowatt microwave at 99° C. for 20 minutes, and the water content of the waste liquid is controlled at 45% to 50%.

[0021] The content of zeolite is 50%-70%, and the specific gravity is 1.94g·cm -3 The high-silica zeolite is ground to a 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com