Moso bamboo cutter

A cutter and moso bamboo technology, applied in wood processing equipment, manual woodworking tools, forestry, etc., can solve the problems of easily cutting others or oneself, dizziness of the operator, and low safety, and achieve simple cutting operation and protection Integrity, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

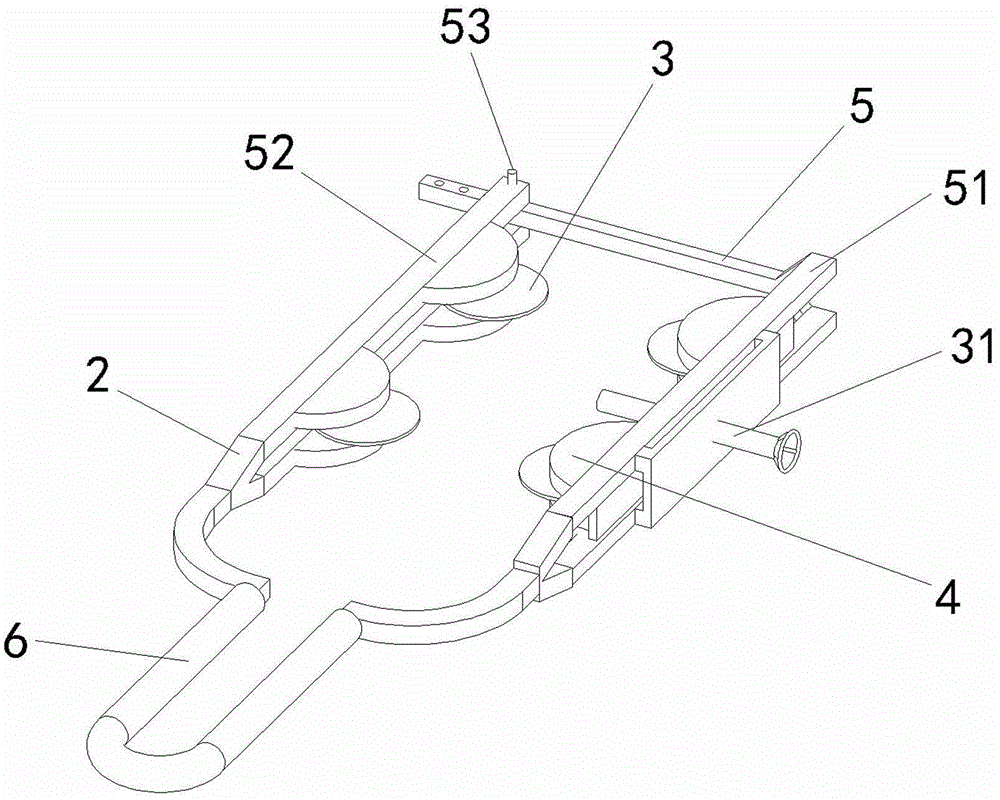

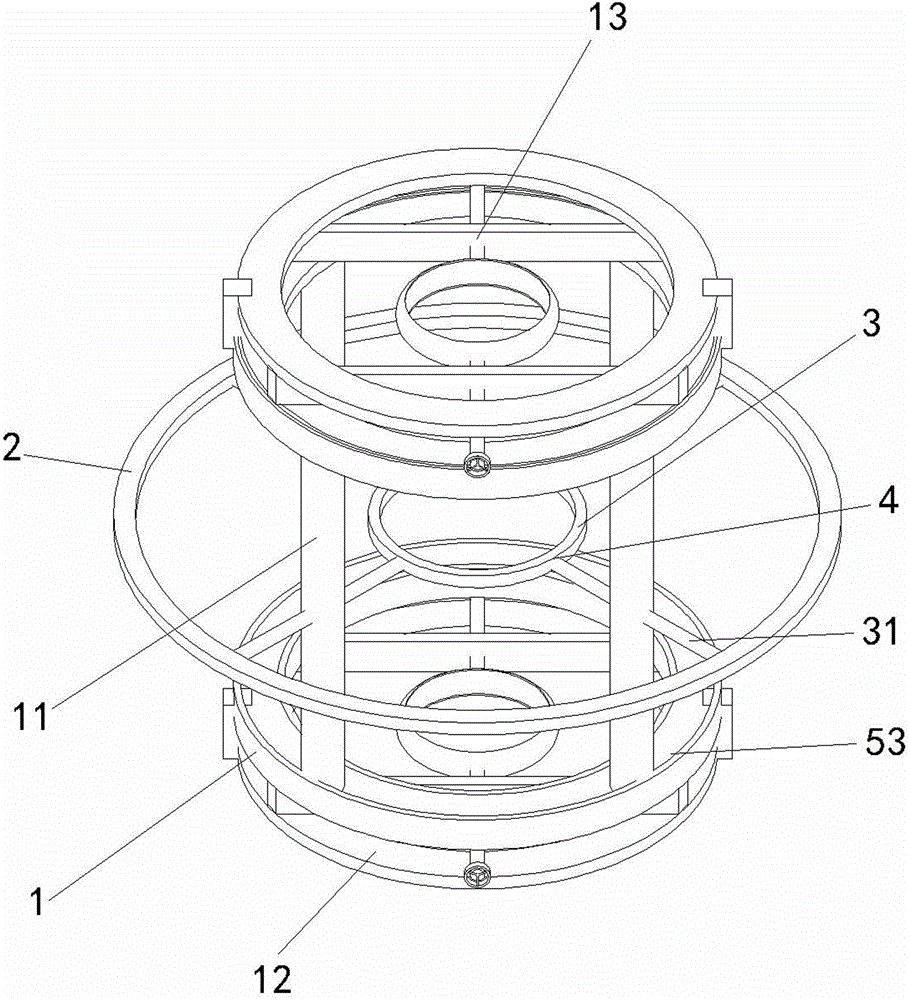

[0018] Embodiment one, such as figure 1 and figure 2 A kind of moso bamboo cutter shown, comprises fixing device 1 and cutting device 2, and fixing device 1 and cutting device 2 are arranged separately and both cooperate with each other, and cutting device 2 comprises a knife group 4 and the adjusting frame of a fixed knife group 4 In structure 5, the knife group 4 is composed of four cutting knives 3, and the centers of the rotating shafts of the cutting knives 3 are connected in a square shape. For the arrangement of the cutting tool 3, the adjustment frame structure 5 is also arranged in a square shape. The adjustment structure 5 includes a base bar 51 and a limit bar 52. The base bar 51 includes a short right-angled side and a long right-angled side. The short right-angled There is a rotating structure 53 part on the side, and the rotating structure 53 includes a row of evenly distributed first fixing holes arranged on the short right-angled side and the second fixing ho...

Embodiment 2

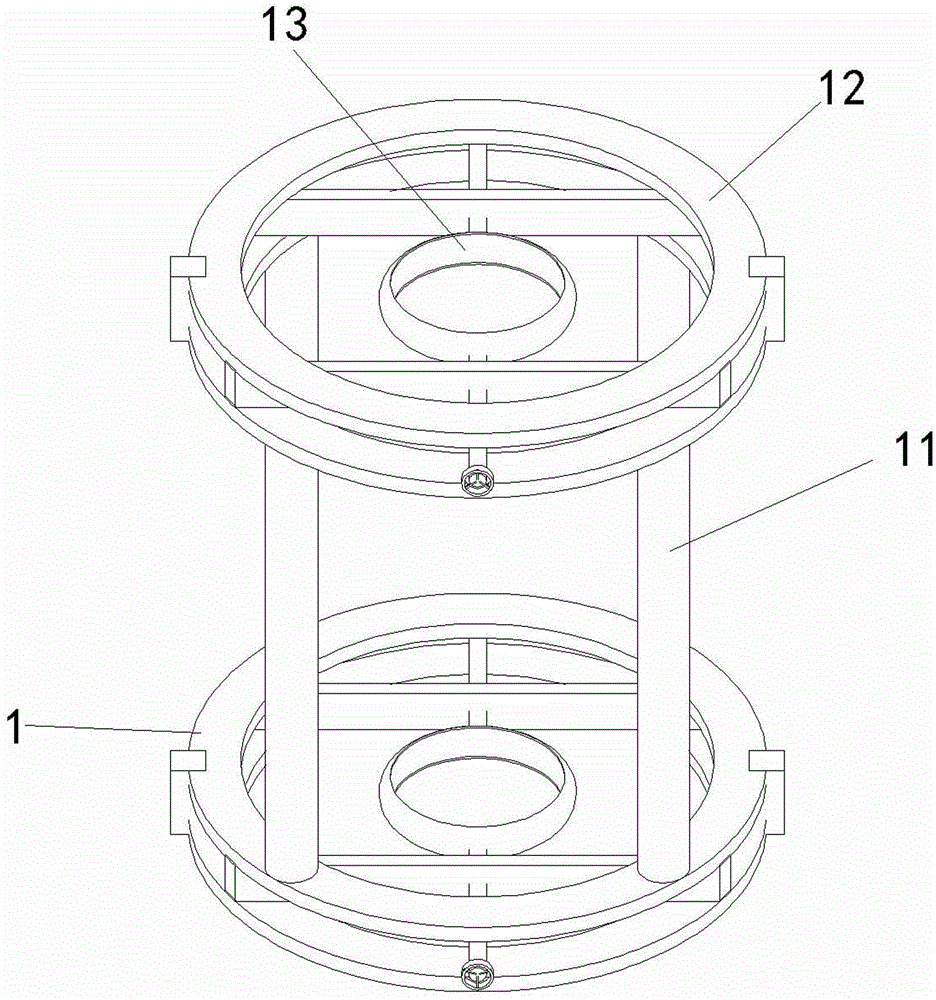

[0022] Embodiment two, such as image 3 As shown, the fixing device 1 includes four liftable fixing rods 11, and the two ends of the fixing rods 11 are respectively provided with limit rings 12, and the limit rings 12 include a first circle and a second circle, between the first circle and the second circle A card and device 13 is provided, and the card and device 13 includes a symmetrically arranged fixed bottom plate, an adjusting screw is arranged on the fixed bottom, one end of the adjusting screw is provided with a control part and the other end is provided with a hoop. The middle part between the fixed bottom plates includes a hinge arranged on one side of the spacer ring 12, and a buckle is arranged on the other side to realize the disassembly of the fixing device.

[0023] The length of the four lifting fixed rods 11 is controlled by adjusting the screw rods, because the fixed rods 11 include a first hollow sleeve and a second hollow sleeve, and a row of wires is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com