The control method of anti-blocking and anti-lost steps of stepping motor

A technology of stepping motors and control methods, applied in heating/cooling equipment, air handling equipment, transportation and packaging, etc., can solve problems such as excessive stalling, inability to judge damper, damper deformation, etc., to improve image and reduce three guarantees Claims and the effect of improving reputation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The specific implementation of the control method for anti-locking and anti-lost steps of the stepping motor of the present invention will be given below in conjunction with the accompanying drawings. However, it should be noted that the implementation of the present invention is not limited to the following embodiments.

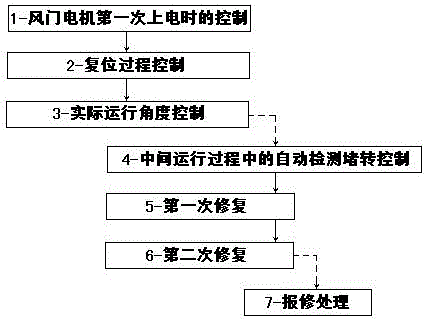

[0072] see figure 1 . A control method for anti-blocking and anti-lost steps of a stepping motor, comprising the following control steps:

[0073] (1) Control when the damper motor is powered on for the first time

[0074] When the HVAC vehicle is powered on for the first time, no matter what the current position is, the damper control should be reset and cleared to make the damper run to the initial position specified by the program; the time of the stall signal can be detected to confirm whether the reset is in place.

[0075] (2) Reset process control

[0076] Carry out unilateral blockage and zero reset calculation on the damper, and zero rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com