A Prestressed Piezoelectric Vibrator Jacquard Yarn Guide Needle

A piezoelectric vibrator and yarn guide needle technology, which is applied in knitting, warp knitting, textiles and papermaking, and can solve the problems of yarn guide needle offset displacement and small output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

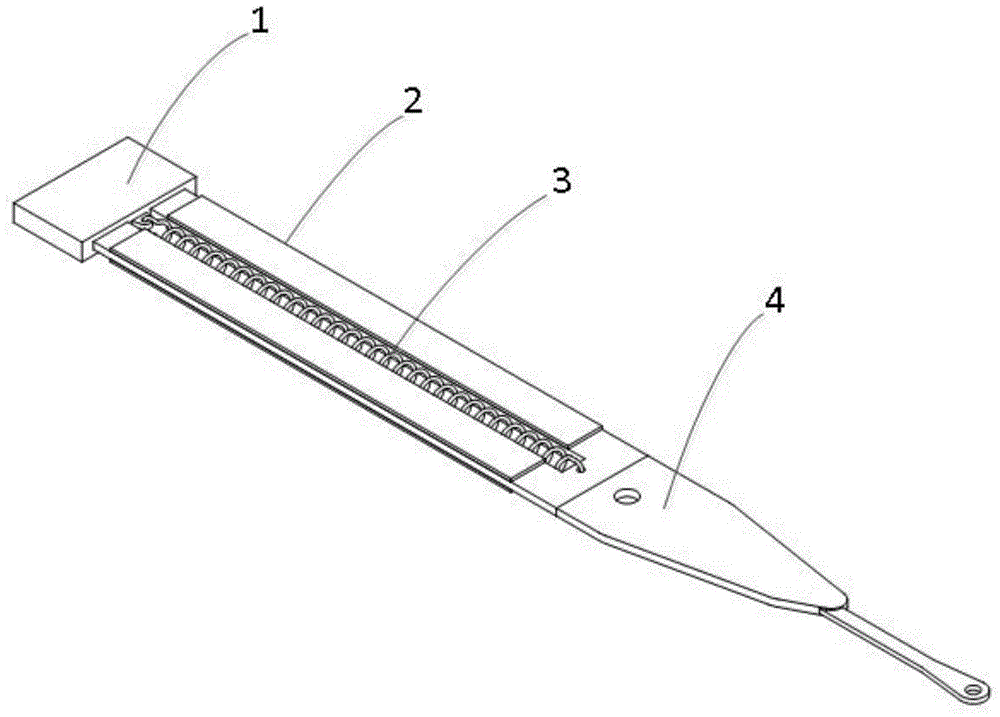

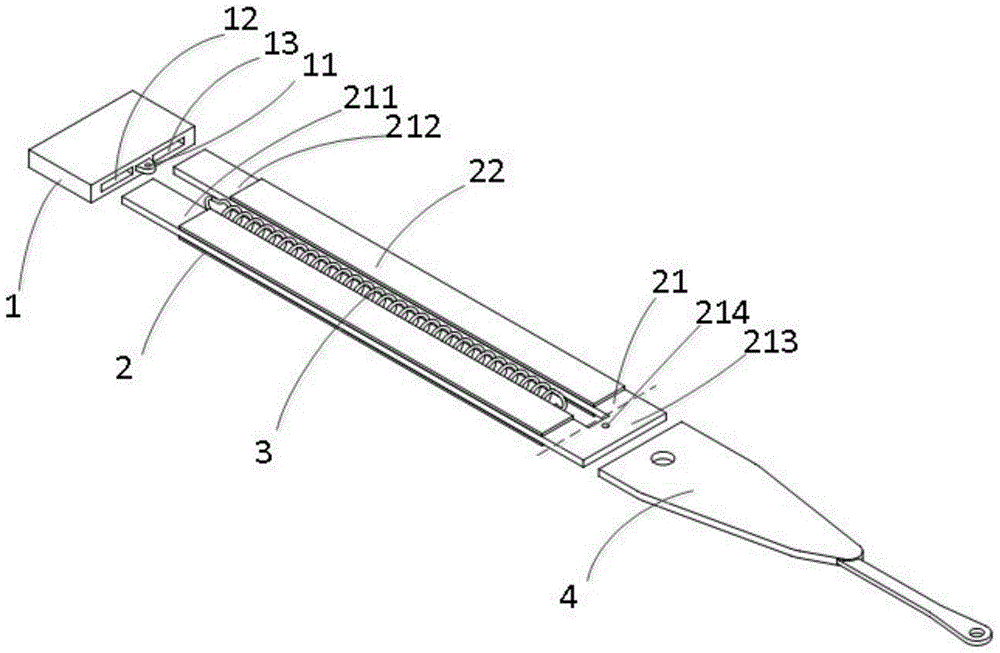

[0013] refer to figure 1 , figure 2 with image 3 , a prestressed piezoelectric vibrator jacquard guide needle of the present invention is composed of a base 1, a piezoelectric vibrator 2, a pretension spring 3 and a needle head 4, wherein:

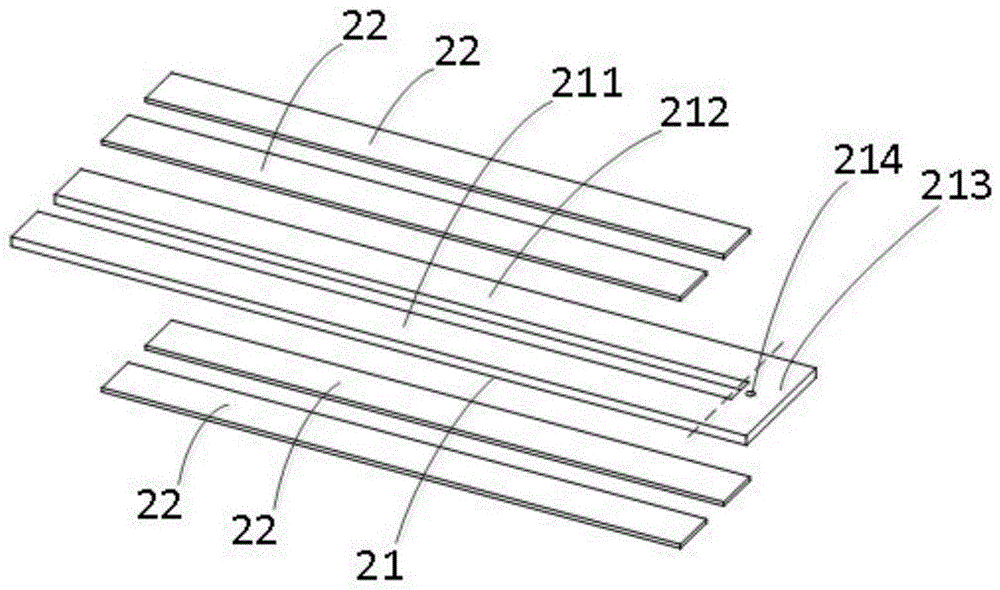

[0014] One side of the base 1 is arranged with a spring mounting ring 11, a first vibrator mounting groove 12 and a second vibrator mounting groove 13; the first vibrator mounting groove 12 and the second vibrator mounting groove 13 have the same size and are about the spring The mounting ring 11 is symmetrically arranged; the piezoelectric vibrator 2 is composed of a U-shaped elastic substrate 21 and a piezoelectric sheet material 22; the U-shaped elastic substrate 21 is a sheet-shaped symmetrical structure, including a first cantilever 211, a second cantilever 212 and Cantilever connection area 213; a spring installation hole 214 is arranged on the cantilever connection area 213, and the spring installation hole 214 is located on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com