A kind of denim fabric processing equipment with frying snowflake device

A technology for denim fabrics and processing equipment, which is applied in the direction of fabric surface trimming, textile material processing, textile and papermaking, etc. The effect of color adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

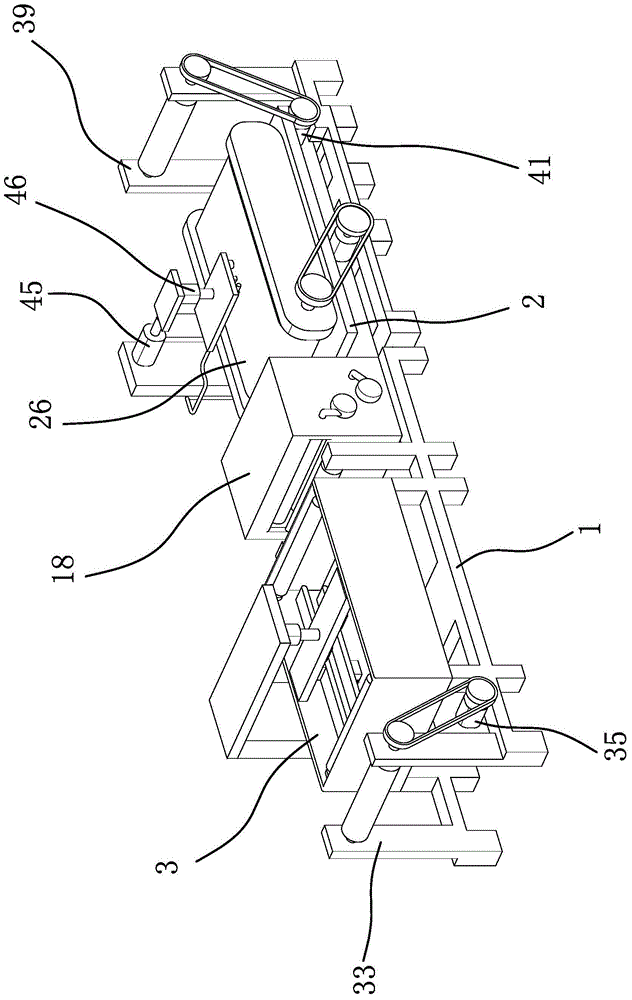

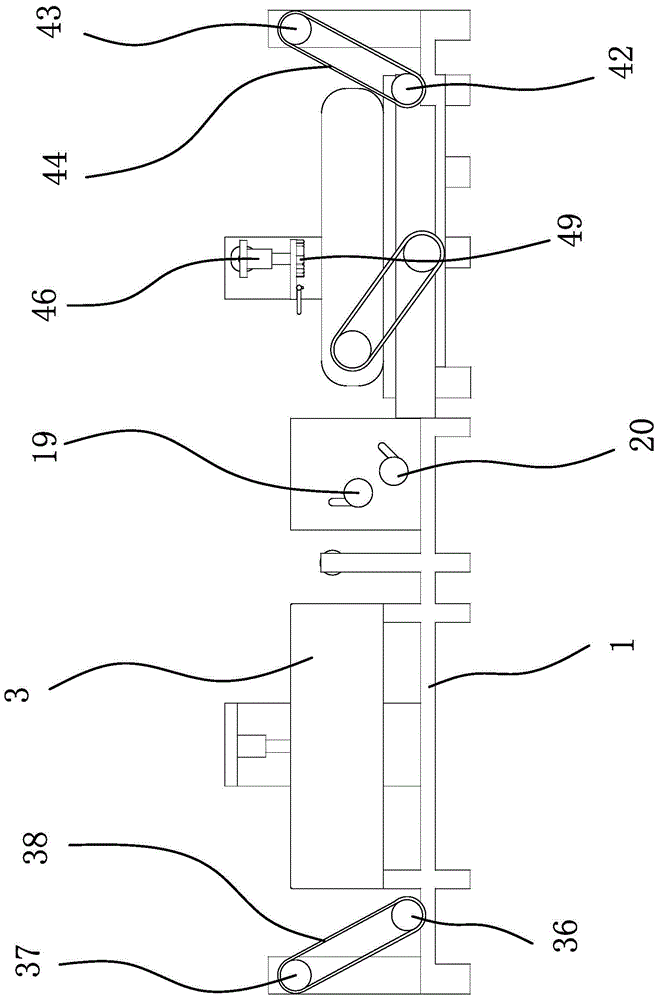

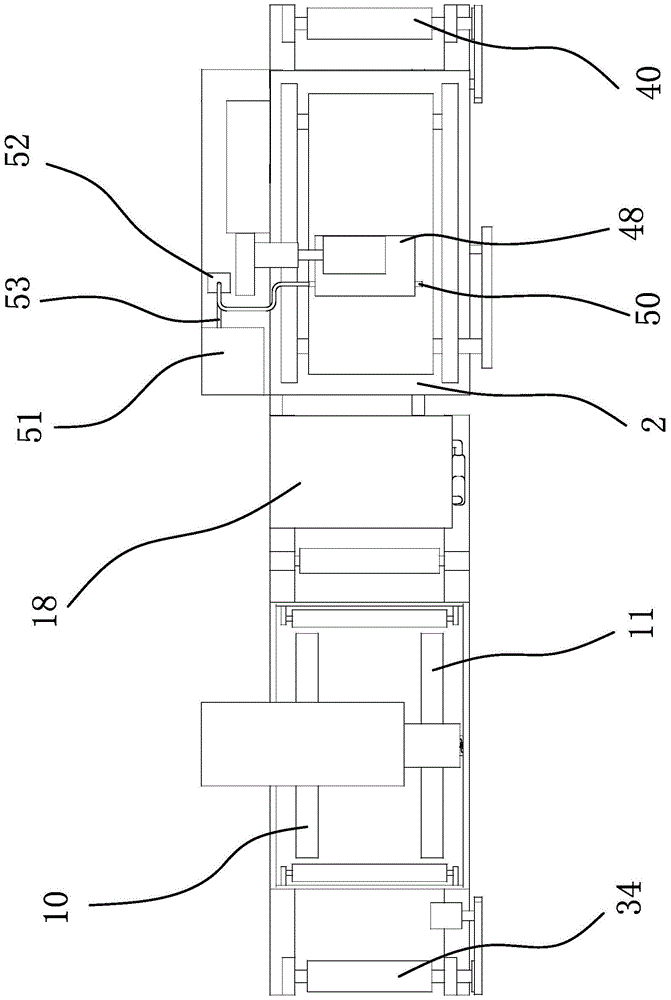

[0030] Such as figure 1 , figure 2 and image 3 As shown, a denim fabric processing equipment with a frying snowflake device includes a frame 1, and two ends of the frame 1 are respectively provided with a feeding mechanism capable of releasing the denim fabric and a material receiving mechanism for winding the denim fabric. A workbench 2 is fixed on the frame 1, and the workbench 2 is between the discharging mechanism and the receiving mechanism, and a dyeing tank 3 and a drying box 18 are arranged successively between the discharging mechanism and the workbench 2. A guide roller is also arranged on the side wall of the inner cavity of the dyeing tank 3, and the guide roller is perpendicular to the transmission directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com