A self-adding dye mechanism for the production and dyeing of intelligently manufactured garment fabrics

A technology of intelligent manufacturing and clothing, applied in the field of clothing manufacturing, can solve the problems affecting the quality of fabrics, instability, dyeing agents affecting the quality of fabrics, etc., and achieve the effect of convenient use and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

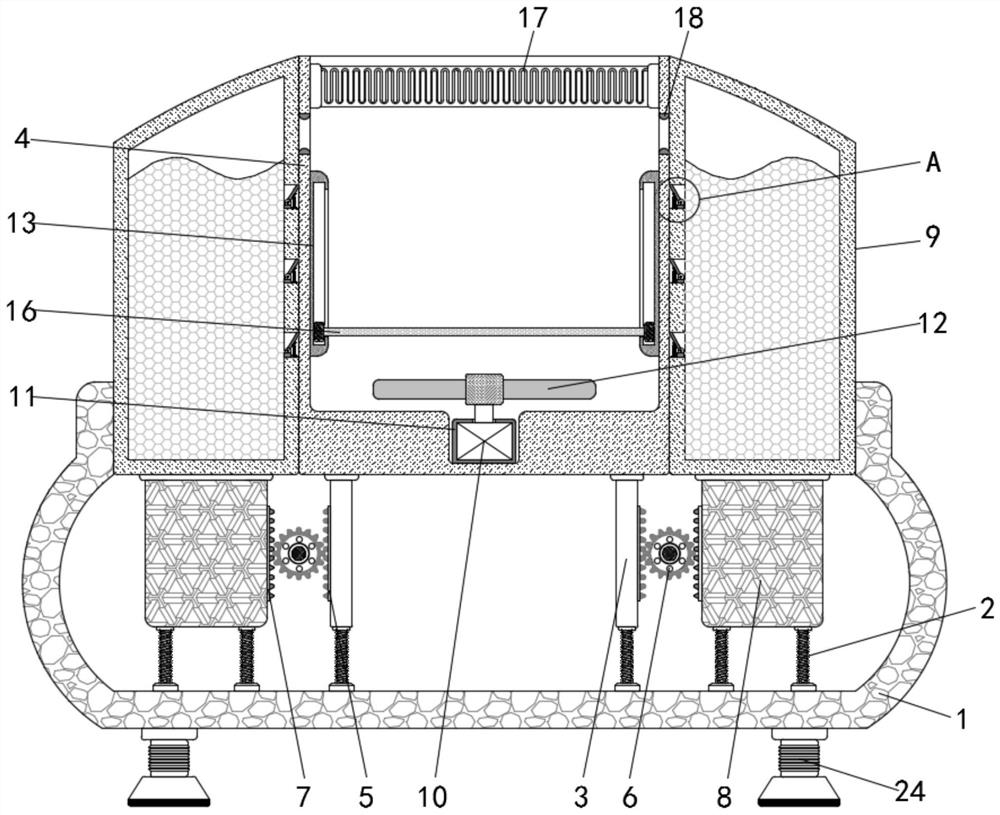

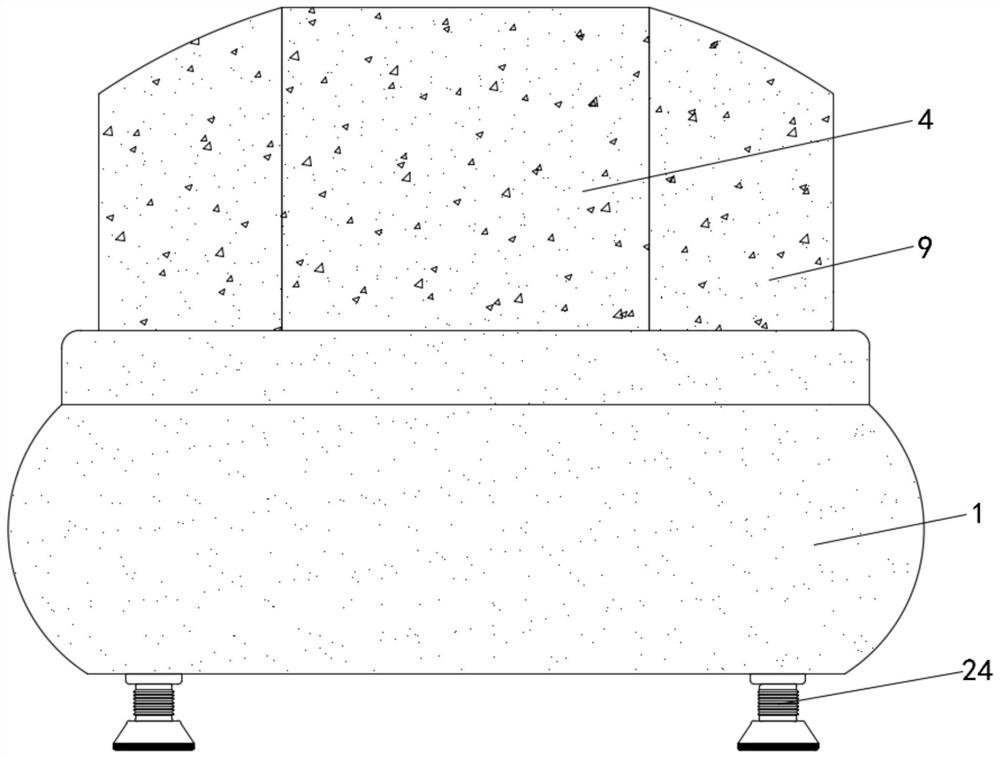

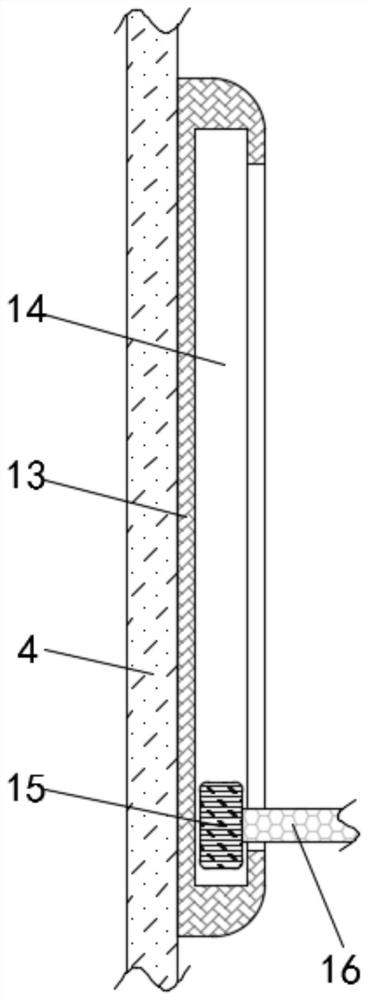

[0022] The present invention is further described below with reference to the accompanying drawings:

[0023] Append figure 1 Attachment Figure 4 Looking:

[0024] The present invention provides an intelligent manufacturing garment fabric production dyeing with self-adding dye mechanism, including the main body 1, the inner wall bottom of the main body 1 is provided with a support spring 2, and the upper end of the support spring 2 is fixedly mounted, and the upper end of the support rod 3 is provided. The dyed box 4 is fixedly mounted, and the two side of the two support rods 3 is provided with the first gear strip 5, and the outer side of the first gear strip 5 is connected to the active gear 6, the axial center of the active gear 6 is movable. There is active bearing, and both ends of the active bearing are connected to the inner wall of the body 1. By providing the active bearing to facilitate the stable mount of the active gear 6, the active gear 6 is away from one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com