High-strength anti-seepage and anti-freezing concrete electric pole

A technology of concrete and concrete layers, applied in the field of concrete poles, can solve the problems of easy corrosion of steel bars, unsuitable for use in areas with harsh environments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

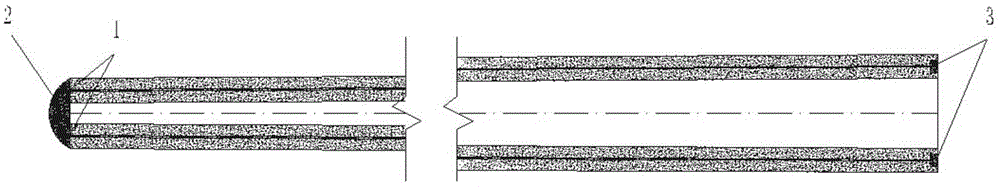

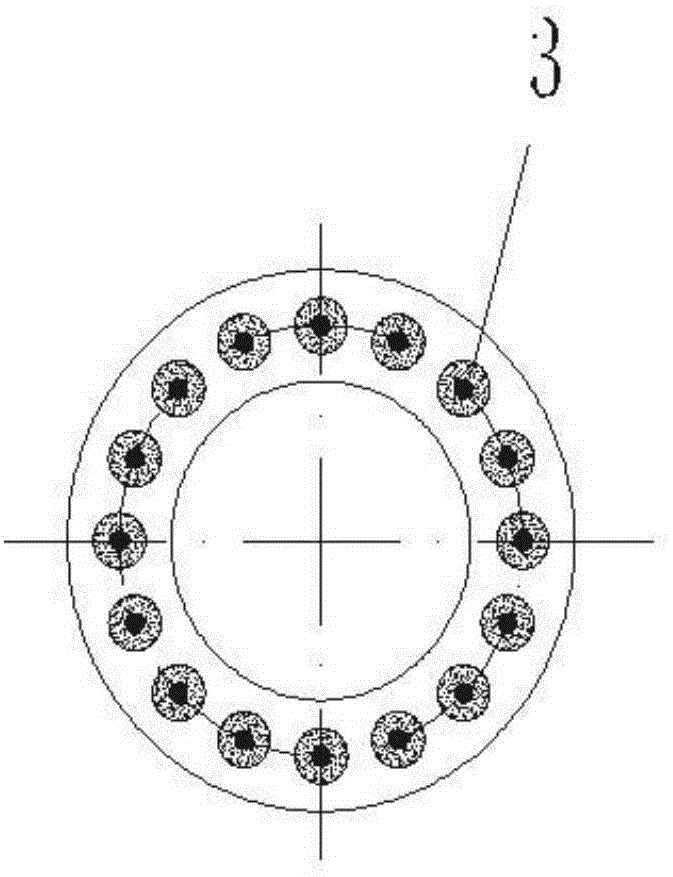

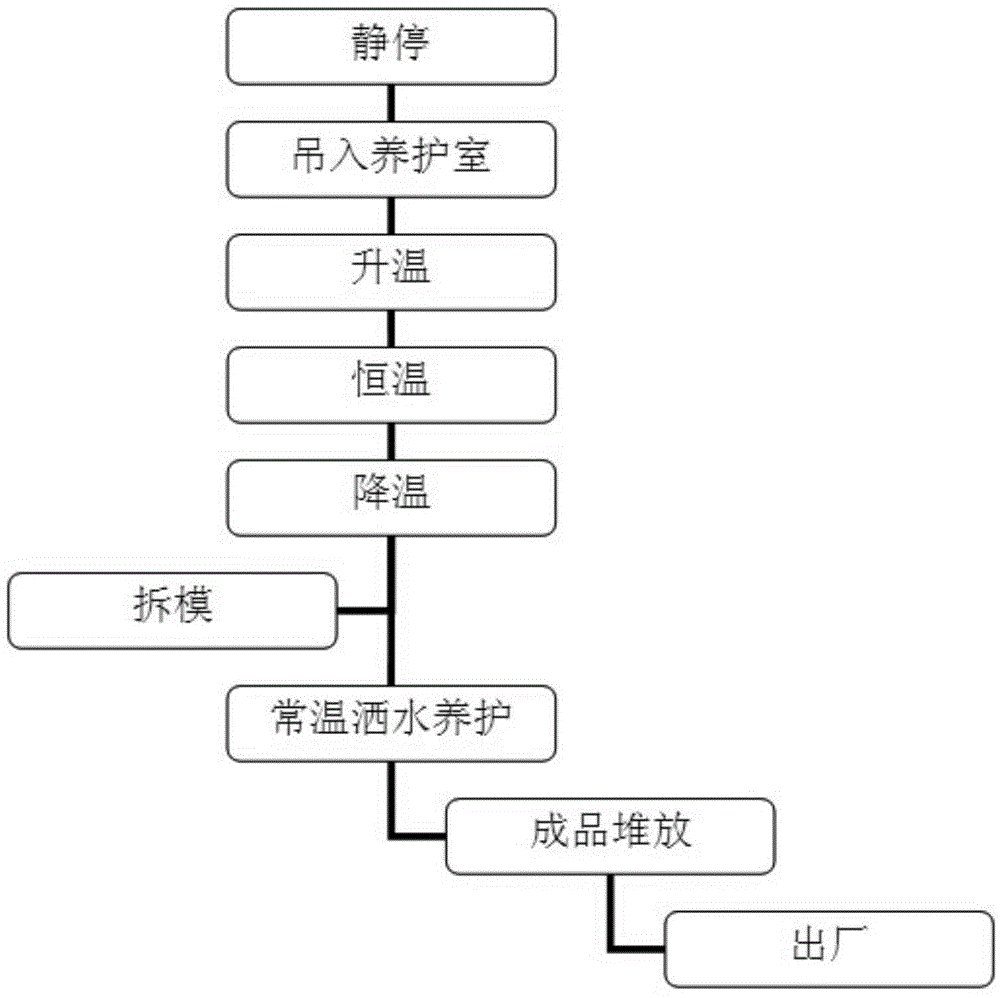

[0105] The high-strength anti-seepage and anti-freeze concrete pole includes a steel skeleton and a concrete layer. The steel skeleton includes erecting rings arranged equidistantly in the vertical direction of the pole and longitudinal prestressed steel bars wrapped with spiral bars. The top of the pole is provided with a sealing cover. The length of the longitudinal prestressed steel bar is smaller than the concrete layer covered by it, and the concrete layer at the bottom of the electric pole is provided with a circular shape coaxially filled with anti-corrosion material corresponding to each steel bar. The pole has a certain taper. The sealing cover is an arc top cover; the depth of the blind hole is 25mm. The head of the steel bar in the blind hole is 10mm, and the thickness of the anti-corrosion material layer is 15mm.

[0106] Anti-corrosion material is concrete.

[0107] Table 1 Concrete mix ratio

[0108]

[0109] No. 1 is ordinary concrete without active admixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com