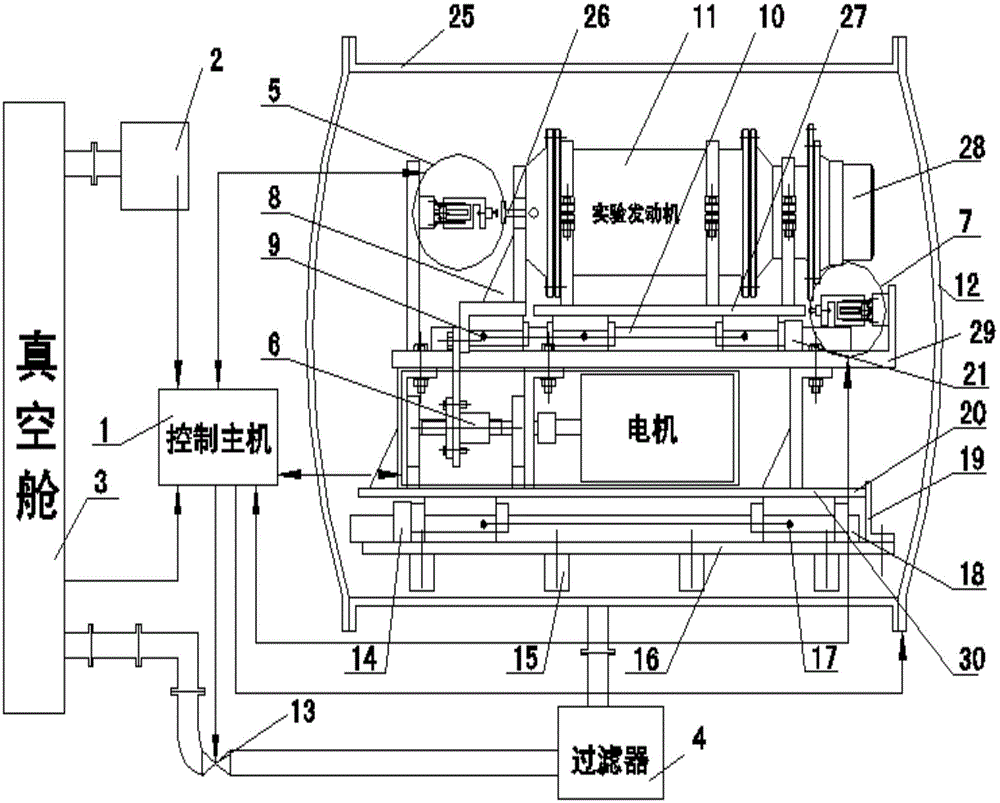

Engine post-thrust measuring device

A measuring device and engine technology, which is applied in the direction of measuring device, engine test, force/torque/power measuring instrument, etc., can solve the problem that the aftereffect thrust of the engine cannot be effectively measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] 1. Press figure 1 As shown, the engine 11 is installed and debugged outside the experimental cabin 25 , and then the engine 11 is pushed into the experimental cabin 25 along the guide rail 10 .

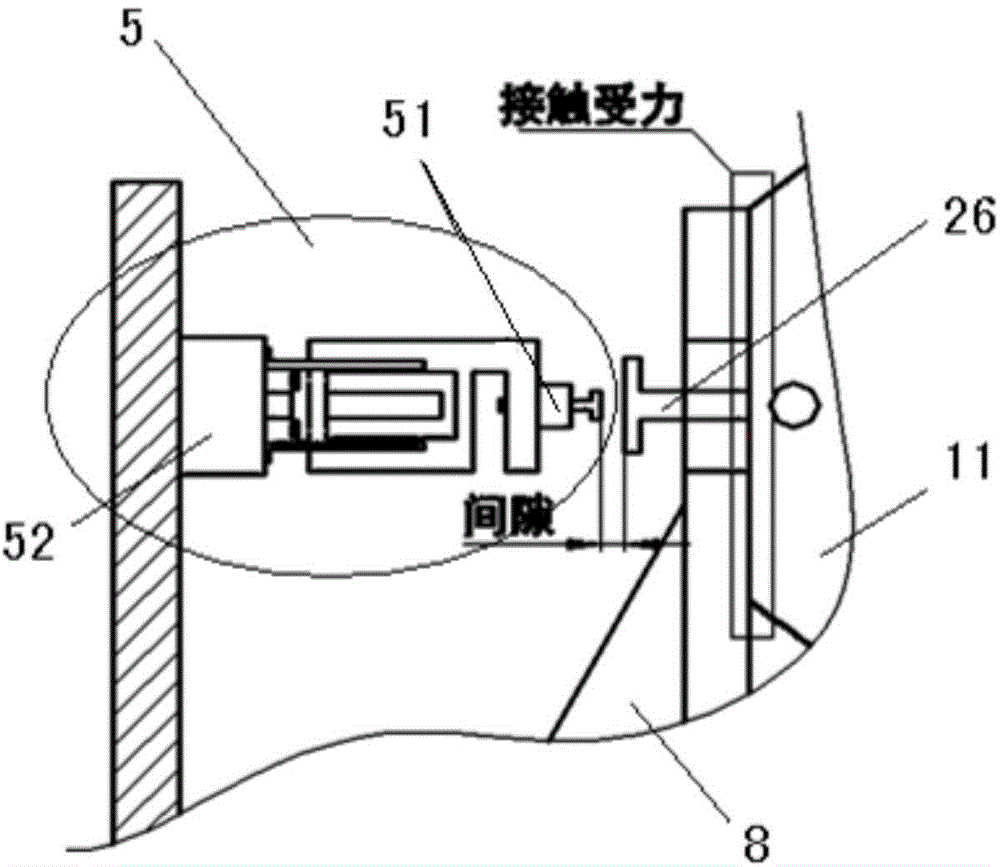

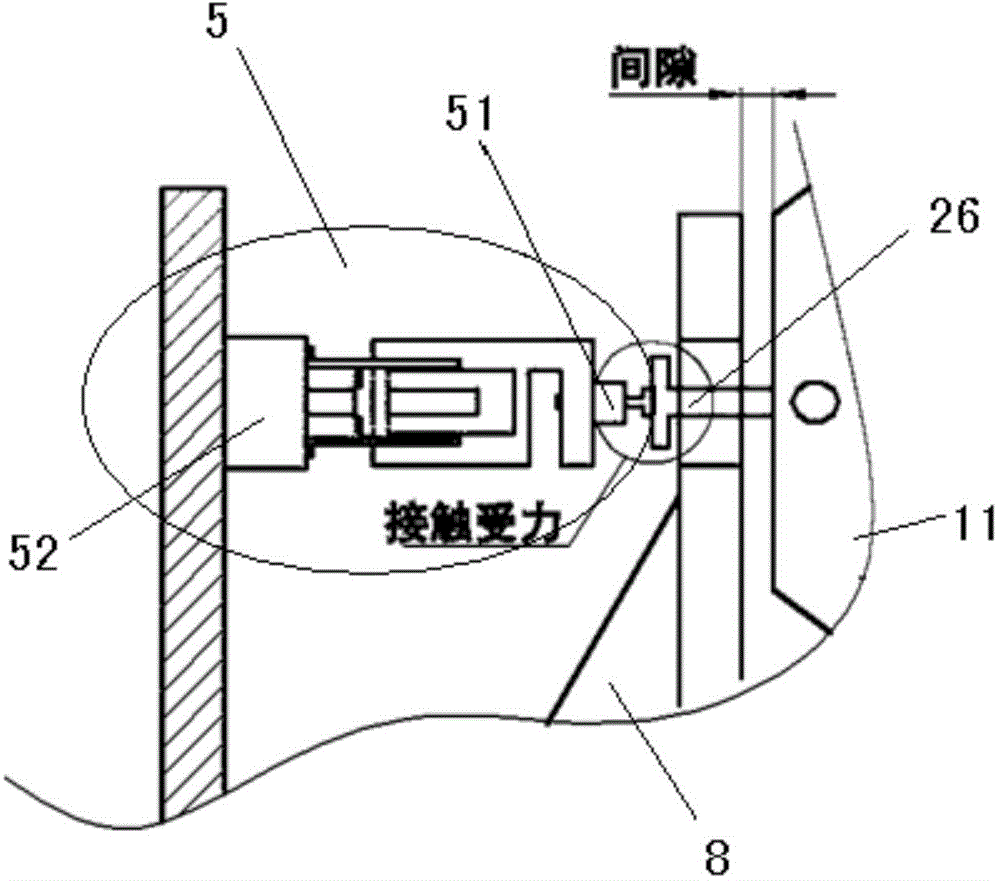

[0040] 2. Before the ignition of the experimental engine 11, close the two-way solenoid valve 13, use the vacuum pump unit 2 to reduce the pressure in the vacuum chamber 1 to 10 Pa below a certain pressure, and maintain the vacuum environment of the vacuum chamber 3. During this working process, the control host 1 monitors the real-time pressure of the vacuum chamber 3 . After the pressure of the vacuum chamber 3 is stabilized below 3000Pa, ensure that the thrust measuring device 5 and the thrust ejector pin 26 of the engine 11 have a certain gap distance, and are in an unstressed state. The electromechanical loading device 6 is controlled by controlling the main engine 1 to drive the thrust pier 8 to be in close contact with the engine 11 . Use slider locking device 21 to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com