Capacitance type touch panel

A capacitive touch and panel technology, applied in electrical digital data processing, instruments, calculations, etc., can solve problems such as malfunction and inability to operate, and achieve the effects of improving reliability, expanding application scope, and improving resolution accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

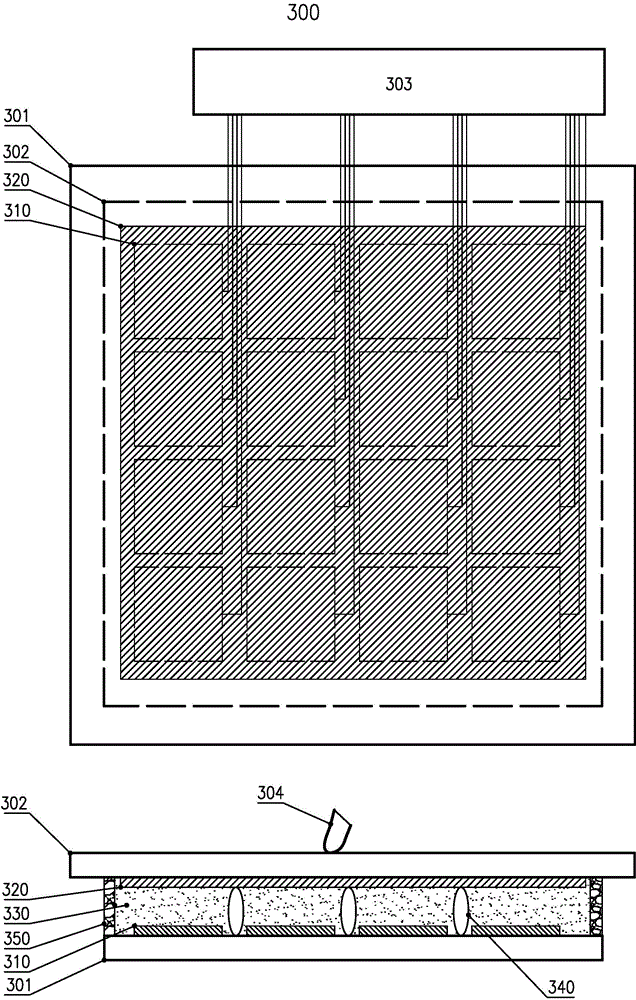

[0035] Such as figure 1 A capacitive touch panel 100 shown includes a touch sensing electrode substrate 101, a touch common electrode substrate 102 and a touch circuit 103; a touch sensing electrode 110 is arranged on the touch sensing electrode substrate 101 , the touch sensing electrode 110 is composed of a plurality of touch sensing electrode units arranged in a single-layer array, each touch sensing electrode unit has an independent lead-out electrode line, and the lead-out electrode line of each touch-sensing electrode unit is connected to the touch sensor circuit 103; the touch common electrode substrate 102 is provided with a touch common electrode 120, the touch common electrode 120 is a single-layer electrode, and the touch common electrode 120 is connected to the touch circuit 103; the touch sensing electrode substrate 101 is On the top, the touch common electrode substrate 102 is on the bottom, the touch common electrode 120 and the touch sensing electrode 110 face ...

specific Embodiment approach 2

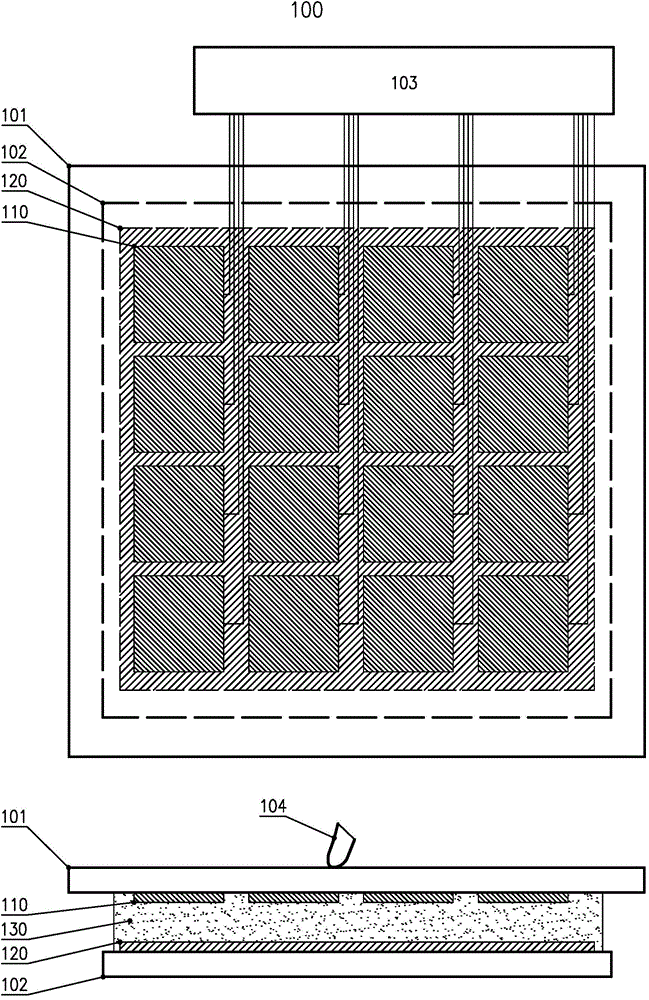

[0040] Such as figure 2 A capacitive touch panel 200 shown includes a touch sensing electrode substrate 201, a touch common electrode substrate 202 and a touch circuit 203; a touch sensing electrode 210 is arranged on the touch sensing electrode substrate 201 , the touch sensing electrode 210 is composed of several touch sensing electrode units arranged in a single-layer array, each touch sensing electrode has an independent lead-out electrode line, and the lead-out electrode line of each touch-sensing electrode unit is connected to the touch circuit 203; the touch common electrode 220 is provided on the touch common electrode substrate 202, the touch common electrode 220 is a planar electrode, and the touch common electrode 220 is connected to the touch circuit 203; the touch sensing electrode substrate 201 is on top, The touch common electrode substrate 202 is below, and the touch common electrode 220 is arranged on the surface of the touch common electrode substrate 202 fa...

specific Embodiment approach 3

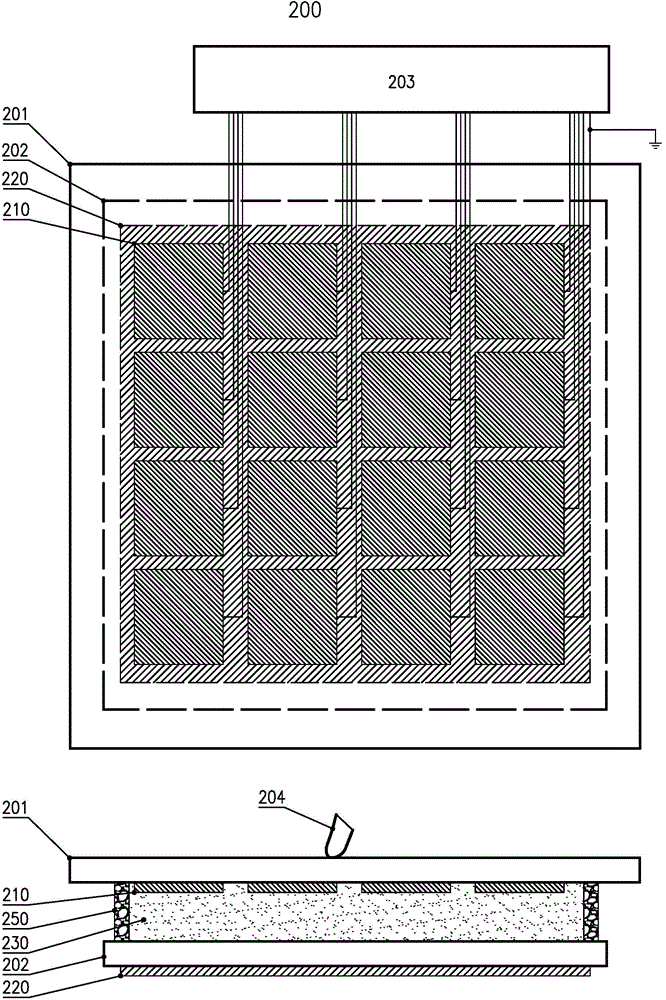

[0045] Such as image 3 A capacitive touch panel 300 shown includes a touch sensing electrode substrate 301, a touch common electrode substrate 302 and a touch circuit 303; a touch sensing electrode 310 is arranged on the touch sensing electrode substrate 301 , the touch sensing electrode 310 is composed of a plurality of touch sensing electrode units arranged in an array, each touch sensing electrode unit has an independent lead-out electrode line, and the lead-out electrode line of each touch-sensing electrode unit is connected to the touch circuit 303 ; Touch common electrode substrate 302 is provided with touch common electrode 320, and touch common electrode 320 is planar electrode, and touch common electrode 320 is connected with touch circuit 303; The sensing electrode substrate 301 is below, and the touch common electrode 320 and the touch sensing electrode 310 face each other, that is, the touch common electrode is arranged on the surface of the touch common electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com