High-precision downhole electromagnetic thickness-measuring caliper

A high-precision, caliper technology, used in wellbore/well components, measurement, earth-moving drilling and production, etc., can solve problems such as single-shot and single-receipt, and achieve the effect of improving resolution, high precision, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

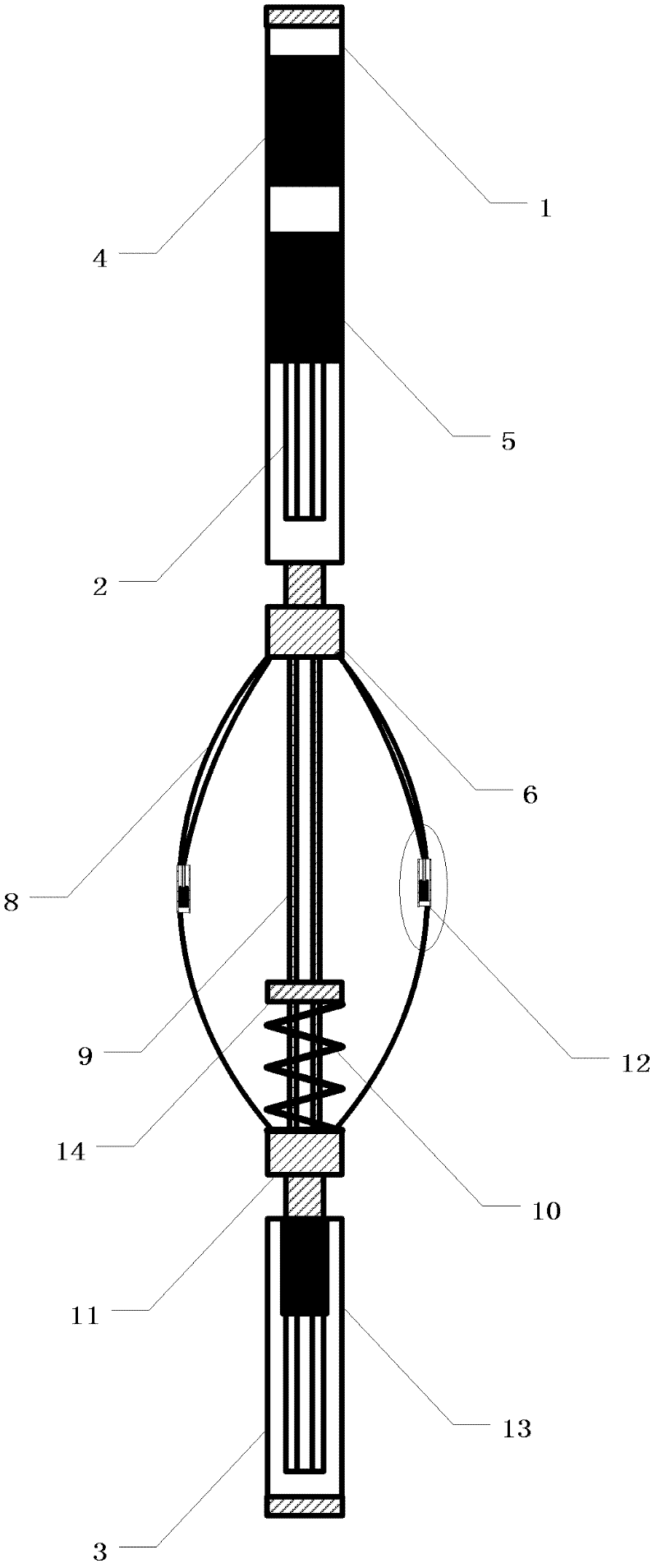

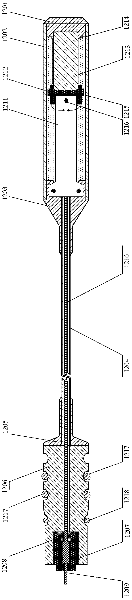

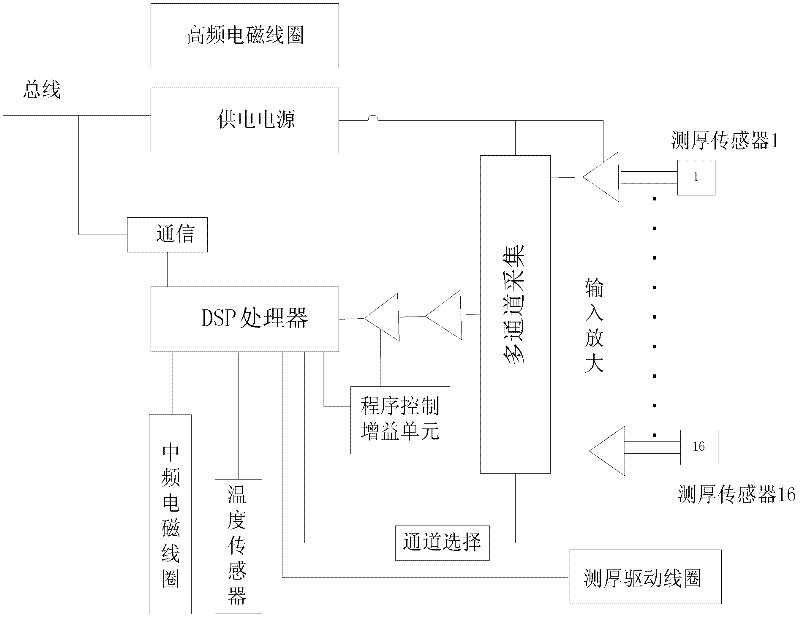

[0030] Such as figure 1 , figure 2 As shown, the high-precision downhole electromagnetic thickness measuring caliper includes a magnetic protection casing 1, a coil assembly, a control unit 2, a thickness measurement unit, a fixed assembly, and a thickness measurement drive unit. The coil assembly and the control unit are both located in the magnetic protection casing. The thickness unit is arranged on the fixed assembly, and the fixed assembly is connected with the magnetic protection cover and the thickness measurement driving unit. The thickness measurement unit includes a plurality of thickness measurement sensors, and the coil assembly includes a high frequency electromagnetic coil and an intermediate frequency electromagnetic coil. Above the coil 5, the intermediate frequency electromagnetic coil 5 is located above the control unit 2, the control unit 2 is connected to the thickness measuring unit through a fixed assembly, and the thickness measuring driving unit is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com