Piezoelectric ceramic with piezoelectric coefficient of d36 and preparation method thereof

A piezoelectric ceramic and piezoelectric coefficient technology, applied in the field of piezoelectric ceramics, can solve the problems of inability to produce, restricting industrial application, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples, but the scope of the present invention is not limited in any way.

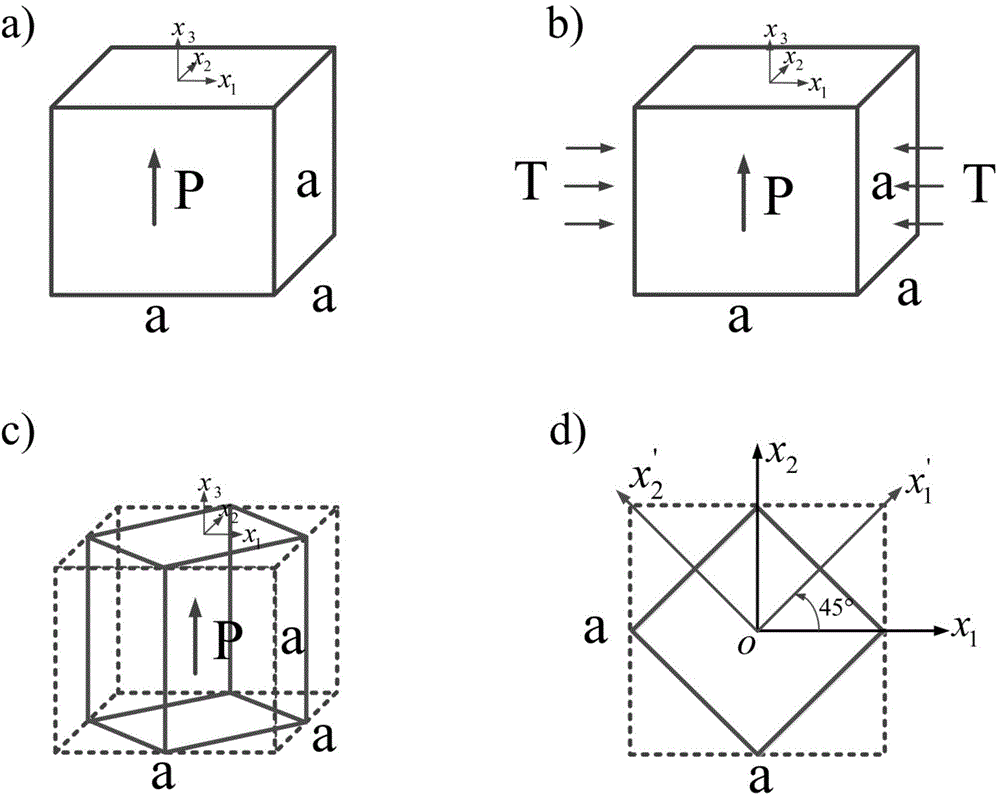

[0038] see figure 1 , follow the steps below to generate the piezoelectric coefficient d in the piezoelectric ceramic 36 :

[0039] (1) if figure 1 As shown in a), the polarized piezoelectric ceramic material is cut into a cube of a×a×a, the polarization direction is as shown, and its coordinate system is x 1 x 2 x 3 . The cube meets international standards for compression test pieces.

[0040] (2) if figure 1 As shown in b), for the cubic piezoelectric ceramic of a×a×a along x 1 direction for uniform compression. The compressive stress T is loaded quasi-statically from zero to 2 to 4 times the coercive stress of piezoelectric ceramics, and kept for about 24 hours, and then slowly unloaded to zero. Aging the compressed ceramics at room temperature for 2-3 days.

[0041] (3) if figure 1 As shown in mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com