A coupling structure terahertz directional coupler

A technology of directional coupler and coupling structure, which is applied to waveguide-type devices, electrical components, connecting devices, etc., can solve the problem of inability to meet the transmission characteristics of terahertz wave transmission lines, surface accuracy and shape and position tolerance requirements are getting higher and higher, performance indicators It is difficult to obtain guarantee and other problems, so as to reduce the processing difficulty and cost, reduce the requirements of dimensional tolerance, and reduce the difficulty and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

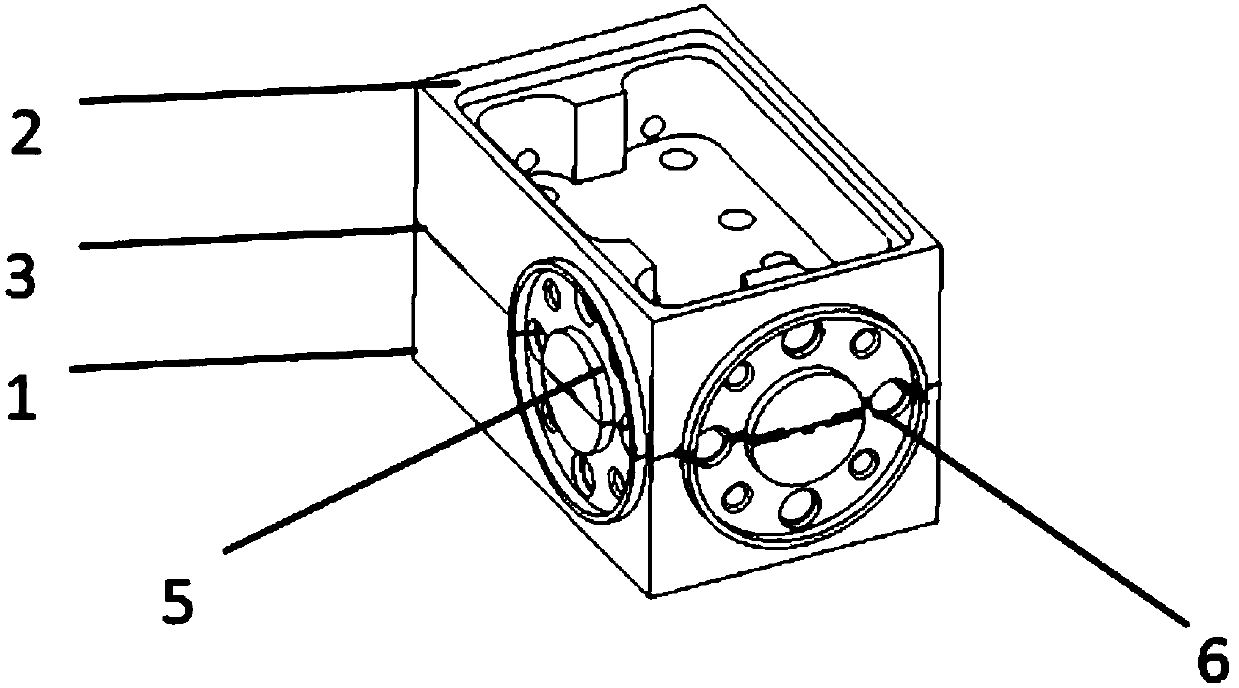

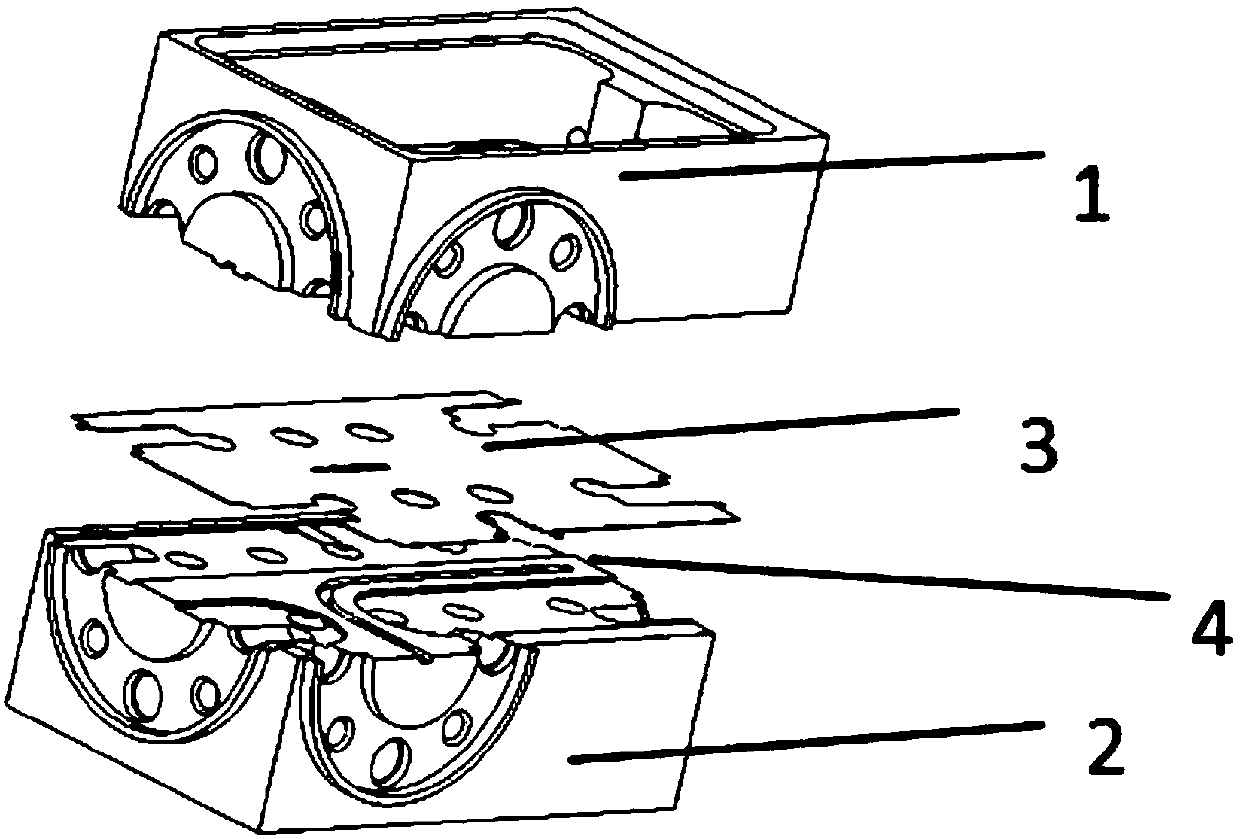

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] Terahertz directional couplers are key devices for signal incidence, reflection and transmission, and are widely used in radar, radiometer, imaging, astronomical observation, environmental detection and security inspection. How to solve the flatness and broadband characteristics of the coupler, as well as the processability and ease of realization in the special frequency band of terahertz, are the primary problems faced by the terahertz directional coupler.

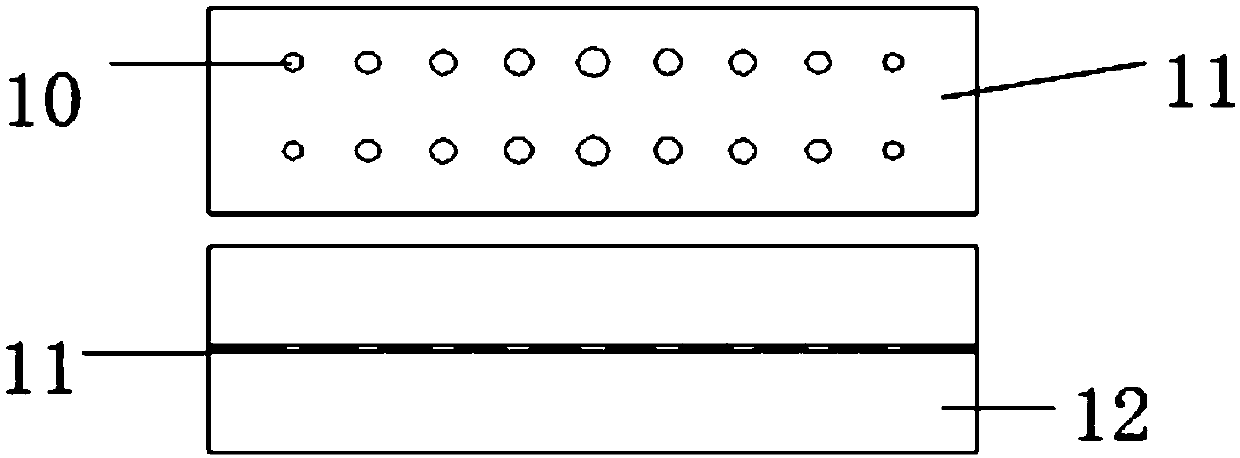

[0026] In the terahertz band, coupling methods such as circular hole coupling, elliptical hole coupling, cross hole coupling and rectangular hole coupling are often used. As the frequency becomes higher and higher, the size of the coupling hole becomes smaller and smaller, which affects the surface accuracy and shape tolerance. The requirements are getting higher and higher, the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com