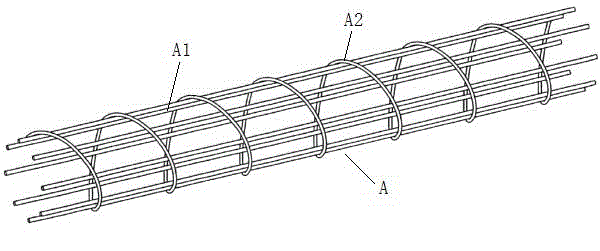

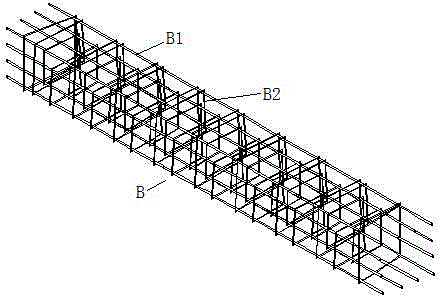

Main rebar bracket of variable spiral continuous stirrup rebar framework forming machine

A steel skeleton and variable helix technology, applied in metal processing equipment and other directions, can solve the problems affecting the overall quality of the steel skeleton, the bending deformation of the main bar, and the shaping of the remaining steel skeleton, and achieve increased adjustment adaptability, effective support, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

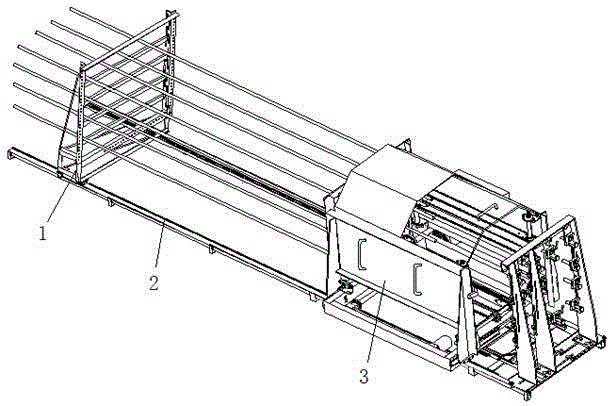

[0018] Such as image 3 As shown, the main reinforcement bracket 1 of the variable spiral continuous stirrup steel frame forming machine of the present invention is installed on the steel frame machine guide rail 2 and is positioned at the rear side of the stirrup box 3 to support the main reinforcement. The device can be set according to the length of the main reinforcement. a.

[0019] Such as Figure 4 As shown, the main reinforcement bracket 1 is mainly composed of a walking frame 4, which is provided with rollers 5 and several brackets 6 for supporting the main reinforcement, and the rollers 5 cooperate with the guide rails 2 laid horizontally by the steel frame machine. The walking frame 4 also includes a main frame and a movable adjustment frame; the main frame is composed of a fixed vertical adjustment frame 9, a fixed horizontal adjustment frame 14 and a balance frame 7, and the three are vertically intersected, wherein the two vertical end faces of the fixed vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com